This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

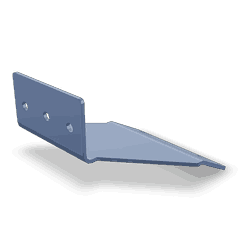

The Cummins 4101024 Water Tube Bracket is a critical component in commercial trucks, specifically designed for the QSK45 CM500 engines. This part plays a significant role in the engine cooling system, contributing to the vehicle’s overall performance and reliability. Understanding its function and importance is essential for maintaining the efficiency of commercial trucks.

Basic Concepts of Water Tube Brackets

A Water Tube Bracket is a component that supports and secures water tubes within an engine’s cooling system. Its primary function is to maintain the structural integrity of the water tubes, ensuring they remain in place and function correctly. This is vital for the cooling system’s efficiency, allowing for proper water flow and temperature regulation, which are crucial for engine performance 1.

Purpose of the 4101024 Water Tube Bracket

The 4101024 Water Tube Bracket is designed to support and secure water tubes in the engine cooling system of a truck. By holding the tubes in place, it ensures that coolant flows efficiently through the system, aiding in the dissipation of heat generated by the engine. This helps maintain optimal engine temperature, which is important for the engine’s longevity and performance 2.

Key Features

This Cummins part is constructed from durable materials, designed to withstand the high temperatures and pressures within an engine cooling system. Its design includes features that enhance its performance and durability, such as precise engineering for a secure fit and resistance to corrosion. These attributes contribute to its reliability and effectiveness in supporting the water tubes.

Benefits

Using the 4101024 Water Tube Bracket can lead to improved engine cooling efficiency, as it ensures that the water tubes are properly positioned and secured. This can enhance the overall performance of the truck’s engine by maintaining optimal cooling. Additionally, its durable construction can result in long-term cost savings by reducing the need for frequent replacements.

Installation Process

Installing this part requires careful attention to ensure it is properly secured and aligned with the water tubes. The process involves using the appropriate tools to fasten the bracket in place, following manufacturer guidelines for torque specifications and alignment. Taking these steps helps ensure the bracket functions correctly and contributes to the efficiency of the cooling system.

Troubleshooting Common Issues

Common issues with the 4101024 Water Tube Bracket may include leaks or structural damage. Troubleshooting these problems involves inspecting the bracket and water tubes for signs of wear or misalignment. Solutions may include tightening connections, repairing leaks, or replacing damaged components to restore the cooling system’s efficiency.

Maintenance Tips

To prolong the lifespan of the 4101024 Water Tube Bracket, regular inspection and cleaning are recommended. This includes checking for signs of wear, corrosion, or damage and ensuring that all connections are secure. Following these maintenance practices can help prevent issues and ensure the bracket continues to support the engine cooling system effectively.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine and component offerings. With a history of innovation and quality, Cummins products are designed to meet the demanding requirements of commercial vehicles, providing reliable performance and efficiency. The company’s reputation is built on a commitment to excellence and customer satisfaction.

Role of Part 4101024 Water Tube Bracket in Engine Systems

The 4101024 Water Tube Bracket is an essential component in the integration of the plumbing system with the aftercooler water system within engine setups. This bracket securely mounts the water tubes, ensuring a stable and leak-free connection between various components.

Integration with Plumbing System

In the plumbing system, the Water Tube Bracket facilitates the secure attachment of water tubes to the engine block and other critical components. This ensures that the water flow is maintained without any disruptions, which is vital for the efficient operation of the cooling system. The bracket’s design allows for easy maintenance and replacement of tubes, reducing downtime during repairs.

Connection to Aftercooler Water System

The aftercooler water system relies on the Water Tube Bracket to maintain the integrity of the water passages that cool the compressed air before it enters the engine. By providing a robust mounting solution, the bracket ensures that the water tubes remain in optimal position, enhancing the efficiency of the aftercooling process. This, in turn, contributes to better engine performance and longevity by preventing overheating.

Enhanced System Reliability

The use of the Water Tube Bracket in both the plumbing and aftercooler water systems enhances the overall reliability of the engine. It ensures that all connections are secure and that the water flow is consistent, which is essential for maintaining the engine’s operating temperature within safe limits. This reliability is particularly important in high-stress environments where engine performance is paramount.

Simplified Maintenance

Incorporating the Water Tube Bracket into the engine systems simplifies maintenance procedures. Mechanics can quickly access and replace water tubes without the need for complex disassembly, which saves time and reduces the risk of errors during reassembly. This ease of maintenance is a significant advantage in both routine servicing and emergency repairs.

Conclusion

The Cummins 4101024 Water Tube Bracket is a vital component in the engine cooling systems of commercial trucks, particularly in the QSK45 CM500 engines. Its role in securing water tubes, facilitating efficient coolant flow, and enhancing engine reliability cannot be overstated. Regular maintenance and proper installation are key to maximizing its benefits and ensuring the longevity and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.