This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

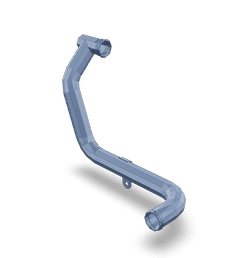

The Cummins 4296727 Water Transfer Tube is a component designed to facilitate the efficient operation of commercial trucks. Its role in the engine cooling system is significant, contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a component within the cooling system of an engine. Its function is to circulate coolant between various parts of the engine, ensuring that heat is evenly distributed and managed. This circulation helps maintain optimal engine temperature, which is vital for efficient operation and longevity of the engine components 2.

Purpose of the 4296727 Water Transfer Tube

The 4296727 Water Transfer Tube plays a role in the engine cooling system by directing coolant flow to critical areas of the engine. This ensures that all parts of the engine remain at an optimal temperature, which contributes to the overall performance and efficiency of the truck. Proper coolant circulation helps prevent overheating, which can lead to engine damage and reduced vehicle performance 3.

Key Features

The 4296727 Water Transfer Tube is constructed from durable materials that are resistant to corrosion and high temperatures. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to withstand the pressures of the cooling system, enhancing its performance and durability 4.

Benefits

Using the 4296727 Water Transfer Tube offers several benefits. It contributes to improved engine cooling efficiency, which can lead to better overall vehicle performance. The tube’s durable construction ensures longevity, even in demanding operating conditions. Its reliable performance helps maintain engine temperature within optimal ranges, reducing the risk of overheating and associated engine damage 5.

Installation Process

Installing the 4296727 Water Transfer Tube requires careful attention to detail. Preparatory steps include ensuring the engine is cool and the cooling system is drained. Tools such as wrenches and sealant may be required. The tube should be fitted according to the manufacturer’s instructions, ensuring all connections are secure and free from leaks. Proper installation is key to ensuring the tube functions correctly within the cooling system 6.

Common Issues and Troubleshooting

Common issues with the 4296727 Water Transfer Tube may include leaks or blockages. Leaks can often be traced to loose connections or damaged fittings, while blockages may result from debris within the cooling system. Troubleshooting steps include inspecting all connections for tightness, checking for signs of corrosion or damage, and ensuring the cooling system is free from contaminants. Addressing these issues promptly can help maintain the efficiency of the cooling system 7.

Maintenance Tips

Regular maintenance of the 4296727 Water Transfer Tube is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, checking connections for tightness, and ensuring the cooling system is clean and free from debris. Following the manufacturer’s recommended maintenance schedule can help prevent issues and ensure the tube continues to function effectively 8.

Compatibility and Application

The 4296727 Water Transfer Tube is designed for use in specific types of trucks and engines. It is important to verify compatibility with the vehicle’s make and model to ensure proper fit and function. This component is commonly used in certain Cummins engine models, contributing to their efficient operation 9.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a broad product range that includes engines, filtration systems, and powertrain components, Cummins has established a reputation for reliability and performance. The company’s history of developing advanced technologies underscores its dedication to meeting the needs of the commercial trucking sector 10.

Role of Part 4296727 Water Transfer Tube in Engine Systems

The 4296727 Water Transfer Tube is an essential component in the efficient operation of various engine systems, particularly those involving fluid dynamics and thermal management. This component is integral in the following systems:

Cooler Systems

In cooler systems, the Water Transfer Tube facilitates the movement of coolant between the engine and the cooler. This ensures that the engine maintains optimal operating temperatures, preventing overheating and potential damage. The tube’s design allows for efficient heat exchange, enhancing the overall performance and longevity of the engine 11.

Torque Converter Oil Systems

Within torque converter oil systems, the Water Transfer Tube plays a significant role in managing the temperature of the torque converter fluid. By transferring coolant to and from the torque converter, it helps maintain the fluid at an ideal temperature, which is essential for smooth operation and efficient power transmission. This, in turn, contributes to the durability and reliability of the torque converter 12.

Plumbing Systems

In the context of plumbing systems, the Water Transfer Tube is used to route coolant through various pathways within the engine compartment. Its precise fitting and sealing properties ensure that there are no leaks, which could lead to inefficient cooling and potential engine damage. The tube’s robust construction also withstands the pressures and temperatures inherent in these systems 13.

Torque Converter Cooler Systems

When integrated into torque converter cooler systems, the Water Transfer Tube enhances the cooling process by efficiently transferring coolant to the torque converter cooler. This setup ensures that the torque converter operates within its specified temperature range, which is vital for maintaining transmission efficiency and preventing thermal stress on the converter components 14.

Conclusion

The 4296727 Water Transfer Tube is a critical component in the cooling systems of several engine models, ensuring that the engine maintains optimal operating temperatures. Its role in various engine systems, including cooler systems, torque converter oil systems, plumbing systems, and torque converter cooler systems, underscores its importance in maintaining engine performance and longevity. Regular maintenance and proper installation are essential to ensure the tube functions effectively within these systems.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.