This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

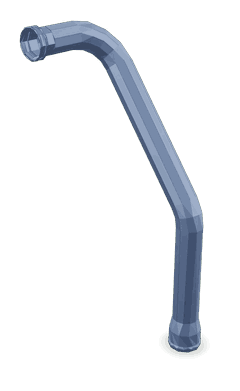

The Water Bypass Tube, identified by the part number 4308860, is a component designed for use in the engine cooling systems of heavy-duty trucks. Its purpose is to regulate the flow of coolant within the system, ensuring that the engine operates within optimal temperature ranges. This regulation is significant for maintaining engine efficiency and longevity, as it helps prevent overheating and ensures consistent performance under various operating conditions 1.

Function and Operation

The Water Bypass Tube operates by controlling the path of coolant flow within the engine cooling system. When the engine is cold, the thermostat remains closed, directing coolant through the bypass tube and back to the engine, allowing for quicker warm-up. As the engine temperature rises, the thermostat opens, allowing coolant to flow through the radiator for cooling. The bypass tube ensures that coolant circulation is maintained even when the thermostat is closed, contributing to stable engine temperatures and efficient operation 2.

Key Features

This Cummins part is constructed with durable materials to withstand the high temperatures and pressures within the engine cooling system. Its design includes precise engineering specifications to ensure a proper fit and function within the system. The tube is made from high-quality materials that offer resistance to corrosion and wear, enhancing its durability and reliability in demanding applications 3.

Benefits

The use of the Water Bypass Tube in the engine cooling system offers several advantages. It contributes to improved engine performance by ensuring that the engine reaches its optimal operating temperature more quickly. This rapid warm-up reduces the time the engine spends in less efficient temperature ranges. Additionally, the tube enhances cooling efficiency by maintaining consistent coolant flow, which helps in dissipating heat more effectively. Prolonged component lifespan is another benefit, as stable engine temperatures reduce the stress on engine components, leading to longer-lasting performance 4.

Installation and Compatibility

Proper installation of the Water Bypass Tube is crucial for its effective operation within the engine cooling system. It is designed to be compatible with specific Cummins engine models, ensuring a seamless integration into the system. During installation, it is important to follow manufacturer guidelines to ensure that the tube is correctly positioned and secured, allowing for optimal coolant flow and system performance 5.

Maintenance and Troubleshooting

Routine maintenance of the Water Bypass Tube is important to ensure its continued efficient operation. This includes regular inspections for signs of wear, corrosion, or leaks. Should any issues such as leaks or blockages arise, troubleshooting steps may involve checking for proper installation, inspecting for damage, and ensuring that all connections are secure. Addressing these issues promptly can help maintain the efficiency of the engine cooling system and prevent more significant problems 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality engine components that meet the demanding requirements of heavy-duty applications. The company’s focus on innovation, quality, and customer satisfaction has established it as a trusted name in the industry, providing reliable solutions for engine performance and efficiency 7.

Conclusion

The Water Bypass Tube (4308860) is a vital component in Cummins engines, ensuring optimal thermal performance and preventing overheating. Its integration into the engine cooling system enhances engine efficiency, extends component lifespan, and contributes to the overall reliability of the engine. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this part in heavy-duty applications.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Kazimierz Lejda and Pawel Wos, Internal Combustion Engines, InTech, 2012.

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩ -

Cummins Inc., Owners Manual for F4.5 CM2620 F139B, Bulletin Number 5579520.

↩ -

Cummins Inc., Owners Manual for F4.5 CM2620 F139B, Bulletin Number 5579520.

↩ -

Cummins Inc., Owners Manual for F4.5 CM2620 F139B, Bulletin Number 5579520.

↩ -

Cummins Inc., Owners Manual for F4.5 CM2620 F139B, Bulletin Number 5579520.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.