This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

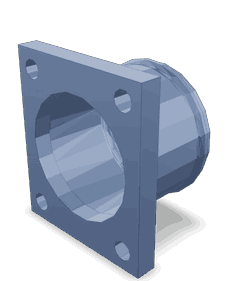

The Cummins 4310911 Water Outlet Connector is a component designed for use in commercial trucks. Its purpose is to facilitate the efficient operation of the engine cooling system. By ensuring proper coolant flow, this connector contributes to maintaining optimal engine temperature, which is vital for the performance and longevity of the engine 1.

Basic Concepts of Water Outlet Connectors

A Water Outlet Connector is a part of the engine cooling system that directs the flow of coolant from the engine to the radiator. It operates by connecting the engine’s water passages to the radiator hose. This connection allows coolant to circulate through the engine, absorbing heat, and then transporting it to the radiator where it is dissipated 2.

Purpose of the 4310911 Water Outlet Connector

The Cummins 4310911 Water Outlet Connector plays a role in the engine cooling system by directing the flow of coolant. It ensures that coolant is evenly distributed throughout the engine, which helps in maintaining consistent temperatures. This is particularly important in commercial trucks, where engines operate under heavy loads and in varying conditions 3.

Key Features

The Cummins 4310911 Water Outlet Connector is constructed from durable materials that can withstand high temperatures and pressures. Its design includes precise fittings to ensure a secure connection to the engine and radiator hose. Additionally, it may feature unique attributes such as enhanced sealing mechanisms to prevent leaks and ensure efficient coolant flow.

Benefits

Using the Cummins 4310911 Water Outlet Connector can lead to improved engine performance due to better temperature regulation. Its reliable construction contributes to the durability of the cooling system, reducing the likelihood of failures. Moreover, the efficient coolant flow it facilitates can enhance the overall reliability of the engine 4.

Installation Process

To install the Cummins 4310911 Water Outlet Connector, begin by ensuring the engine is cool and the cooling system is depressurized. Disconnect the old connector, if present, and clean the mating surfaces. Position the new connector and secure it according to the manufacturer’s instructions, using the appropriate tools. Finally, refill the cooling system with coolant and check for leaks.

Common Issues and Troubleshooting

Issues with the Water Outlet Connector may include leaks or blockages. To address leaks, inspect the connector for signs of wear or damage and replace it if necessary. For blockages, ensure that the coolant passages are clear and free from debris. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

To ensure the longevity and efficiency of the Cummins 4310911 Water Outlet Connector, regular maintenance is recommended. This includes periodic inspection for signs of wear, ensuring secure connections, and checking for leaks. Additionally, maintaining the proper coolant level and quality is important for the overall health of the engine cooling system.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer in the commercial truck industry, known for its range of high-quality engine and component products. With a history of innovation and a strong reputation for reliability, Cummins provides a variety of parts designed to enhance the performance and durability of commercial vehicles.

Compatibility with Cummins Engines

QST30 CM2350 T101 and QST30 CM552

The Water Outlet Connector part 4310911 is specifically engineered to fit the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of the Cummins QST30 series, known for their robust performance and reliability in various industrial and commercial applications. The connector’s design ensures a secure and leak-proof connection, which is essential for maintaining the integrity of the cooling system.

Integration with the Thermostat Housing

The Water Outlet Connector interfaces directly with the thermostat housing. This connection is essential for regulating the flow of coolant into and out of the engine block. The thermostat housing, equipped with a thermostat, controls the coolant flow based on the engine’s temperature. The Water Outlet Connector ensures a secure and leak-free connection, allowing the thermostat to function effectively in managing thermal conditions within the engine.

Contribution to the Cooling System

Within the cooling system, the Water Outlet Connector plays a significant role in maintaining consistent coolant flow. It connects to the engine block and radiates, facilitating the circulation of coolant that absorbs heat from the engine components. This continuous flow helps in dissipating heat, preventing overheating, and ensuring the engine operates within safe temperature ranges.

Auxiliary Cooling Systems

In engines equipped with auxiliary cooling systems, the Water Outlet Connector is equally important. These systems may include additional radiators or cooling loops designed to handle specific thermal loads, such as those from turbochargers or aftercoolers. The connector ensures that the main coolant system can interface seamlessly with these auxiliary systems, enhancing overall cooling efficiency and reliability.

Ensuring Structural Integrity in the Arrangement

The arrangement of components within the engine bay is meticulously designed to optimize performance and accessibility. The Water Outlet Connector contributes to this arrangement by providing a stable and reliable connection point. Its placement and design allow for easy maintenance and replacement, ensuring that the cooling system remains functional and efficient over the engine’s lifespan.

Conclusion

The Cummins 4310911 Water Outlet Connector is a key component in the engine’s cooling system, facilitating efficient coolant flow and ensuring the engine operates within optimal temperature ranges. Its integration with the thermostat housing, contribution to the main and auxiliary cooling systems, and role in the overall component arrangement underscore its importance in engine performance and reliability.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B3.9 CM2880 B194G. Bulletin Number 6320164.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.