This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4916497 Water Transfer Tube is a component designed to facilitate the efficient circulation of coolant within the engine cooling system of heavy-duty trucks. Its role is significant in maintaining the optimal operating temperature of the engine, which is important for performance and longevity.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of the engine cooling system. Its function is to ensure that coolant is evenly distributed, which helps in dissipating heat generated by the engine. This process is vital for maintaining the engine’s temperature within a specified range, which enhances efficiency and prevents overheating 1.

Purpose of the 4916497 Water Transfer Tube

This Cummins part is integral to the operation of a truck’s engine. It plays a role in circulating coolant throughout the engine, ensuring that all components are adequately cooled. By maintaining a consistent coolant flow, it helps in stabilizing the engine temperature, which is important for the engine’s performance and durability.

Key Features

The Cummins 4916497 Water Transfer Tube is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures typical of heavy-duty engine environments. The tube’s design facilitates efficient coolant flow, and its material composition ensures durability and resistance to corrosion.

Benefits

Utilizing the Cummins 4916497 Water Transfer Tube offers several advantages. It contributes to improved engine cooling efficiency, which can lead to better overall engine performance. The tube’s durable construction ensures reliability over time, reducing the likelihood of failures. Additionally, its efficient design helps in maintaining optimal engine temperature, which is beneficial for the engine’s longevity.

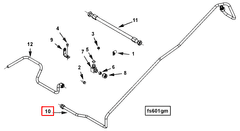

Installation Process

Installing the 4916497 Water Transfer Tube involves several steps. It is important to ensure that the engine is cool before beginning the installation. The old tube, if present, should be removed carefully to avoid damaging surrounding components. The new tube should be positioned according to the manufacturer’s guidelines, ensuring a secure fit. Tools required may include wrenches and possibly a sealant to ensure a leak-free connection.

Maintenance Tips

To ensure the long-term performance of the 4916497 Water Transfer Tube, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning to remove any buildup that could impede coolant flow, and adhering to recommended replacement intervals to prevent potential failures.

Troubleshooting Common Issues

Common issues with the 4916497 Water Transfer Tube may include leaks or blockages. If a leak is detected, it is important to identify the source and address it promptly to prevent coolant loss. Blockages can be resolved by cleaning the tube or, if necessary, replacing it. Regular maintenance can help in identifying and resolving these issues before they lead to more significant problems.

About Cummins

Cummins Inc. is a well-established name in the automotive industry, known for its high-quality engine components. With a history of innovation and commitment to excellence, Cummins has built a reputation for manufacturing reliable and efficient engine parts. Their products are designed to meet the demanding requirements of heavy-duty applications, ensuring performance and durability.

Water Transfer Tube (Part 4916497) in Cummins Engines

The Water Transfer Tube (part 4916497) is a critical component in the cooling system of various Cummins engines, including the QSK60 and CM500 series. This part is integral to maintaining the optimal operating temperature of the engine by facilitating the transfer of coolant between different parts of the engine’s cooling system.

QSK60 Series

In the QSK60 series, the Water Transfer Tube is designed to ensure efficient coolant flow, which is crucial for the engine’s performance and longevity. The QSK60 engines are known for their robust design and are often used in heavy-duty applications, such as marine and industrial settings. The Water Transfer Tube in these engines helps to maintain a consistent temperature, preventing overheating and ensuring that the engine operates within its specified parameters.

CM500 Series

Similarly, in the CM500 series, the Water Transfer Tube plays a vital role in the engine’s cooling system. The CM500 engines are typically used in on-highway and vocational applications, where reliable performance is essential. The Water Transfer Tube in these engines ensures that the coolant is distributed evenly, which helps to dissipate heat effectively and maintain the engine’s efficiency.

Integration and Functionality

The Water Transfer Tube is engineered to fit seamlessly into the cooling system architecture of both the QSK60 and CM500 engines. It is designed to withstand the high pressures and temperatures associated with these engines, ensuring durability and reliability. The tube is typically made from high-quality materials that resist corrosion and degradation, which is crucial for maintaining the integrity of the cooling system over time.

By ensuring that the coolant is transferred efficiently, the Water Transfer Tube helps to prevent hotspots and thermal stress, which can lead to engine damage. This part is a key component in the overall cooling strategy of these engines, contributing to their overall performance and longevity.

Role of Part 4916497 Water Transfer Tube in Engine Systems

The 4916497 Water Transfer Tube is an integral component in the efficient operation of various engine systems, particularly those involving cooling and fuel management.

In the context of a cooler system, the Water Transfer Tube facilitates the movement of coolant between the engine and the cooler. This ensures that the engine maintains optimal operating temperatures, preventing overheating and potential damage. The tube’s design allows for consistent coolant flow, which is essential for the cooler to effectively dissipate heat away from the engine.

When integrated into a fuel system, the Water Transfer Tube plays a role in temperature regulation of the fuel. By transferring coolant to the fuel lines or fuel cooler, it helps in maintaining the fuel at a stable temperature. This is particularly important in high-performance engines where fuel temperature can significantly affect combustion efficiency and engine performance.

In plumbing systems, the Water Transfer Tube is used to connect various components such as the radiator, thermostat housing, and water pump. Its reliable construction ensures that coolant is efficiently circulated throughout the engine bay, contributing to the overall cooling efficiency of the system.

For fuel cooler applications, the Water Transfer Tube is essential in transferring coolant to the fuel cooler. This aids in regulating the temperature of the fuel, which is critical for maintaining consistent fuel viscosity and preventing issues such as fuel gelling or waxing in extreme temperatures.

Overall, the 4916497 Water Transfer Tube is a versatile component that enhances the performance and reliability of engine systems by ensuring proper coolant circulation and temperature management.

Conclusion

The Cummins 4916497 Water Transfer Tube is a vital component in the cooling systems of heavy-duty engines, ensuring efficient coolant circulation and temperature management. Its robust design and durable construction contribute to the overall performance and longevity of the engine. Regular maintenance and prompt troubleshooting of common issues are essential for the continued reliability of this part.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.