This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

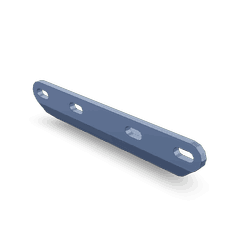

The Water Tube Bracket, identified by Part #4916576, is a component manufactured by Cummins, a leader in the commercial truck industry. This bracket is integral to the cooling system of truck engines, ensuring efficient operation and longevity of the engine. Cummins, known for its robust and reliable engine parts, designs the Water Tube Bracket to meet the demanding requirements of commercial trucking 1.

Function and Operation

The Water Tube Bracket plays a role in the engine cooling system by supporting the water tubes. These tubes are responsible for circulating coolant through the engine to dissipate heat. The bracket ensures that the tubes are securely held in place, allowing for optimal coolant flow and heat exchange. By maintaining the structural integrity of the water tubes, the bracket contributes to the overall efficiency of the cooling system, which is vital for engine performance and longevity 2.

Key Features

The Water Tube Bracket is designed with specific characteristics to ensure durability and effectiveness. Constructed from high-quality materials, it exhibits resistance to high temperatures and corrosion, which are common in the harsh environments of commercial trucking. Its design is tailored to fit Cummins engines precisely, ensuring compatibility and reliable performance. The bracket’s robust construction supports the water tubes under various operating conditions, enhancing the cooling system’s reliability 3.

Benefits

Utilizing the Water Tube Bracket offers several advantages. It contributes to improved engine performance by ensuring efficient coolant circulation, which helps maintain optimal engine temperatures. The bracket’s durable construction enhances the longevity of the cooling system components, reducing the need for frequent replacements. Additionally, its reliable operation supports consistent cooling system performance, which is crucial for the overall efficiency and reliability of the truck engine 4.

Installation and Maintenance

Proper installation of the Water Tube Bracket is crucial for its effective operation. It should be securely fastened to the engine, following the manufacturer’s guidelines to ensure it is correctly positioned and tightened. Regular maintenance checks are recommended to ensure the bracket remains in good condition. This includes inspecting for any signs of wear, corrosion, or damage and addressing these issues promptly to prevent potential cooling system failures.

Troubleshooting Common Issues

Typical problems associated with the Water Tube Bracket may include leaks or structural damage. If leaks are detected, it is important to inspect the bracket and water tubes for any signs of wear or misalignment. Structural damage may require replacement of the bracket to ensure the integrity of the cooling system. Regular inspections and maintenance can help identify and address these issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable engine components. Their product range includes a variety of engines and parts designed to meet the needs of different applications, ensuring optimal performance and durability in demanding environments.

Water Tube Bracket 4916576 Compatibility with Cummins Engines

The Water Tube Bracket part number 4916576, manufactured by Cummins, is a critical component in the engine cooling system. This part is designed to securely hold water tubes in place, ensuring efficient heat transfer and maintaining optimal engine temperatures.

QSK60 and CM850 Engines

The QSK60 and CM850 engines, both high-performance diesel engines, benefit from the precise engineering of the 4916576 Water Tube Bracket. These engines are known for their robust construction and reliability, often used in heavy-duty applications such as marine and industrial sectors. The bracket’s design ensures that water tubes are properly aligned and secured, which is crucial for the efficient operation of these powerful engines.

MCRS Engines

The MCRS engines, another series of Cummins engines, also utilize the 4916576 Water Tube Bracket. These engines are typically employed in medium-duty applications, providing a balance between power and efficiency. The bracket’s role in these engines is to maintain the integrity of the water tube system, which is essential for preventing overheating and ensuring consistent performance.

Grouping of Engines

The QSK60 and CM850 engines, due to their similar high-performance nature, can be grouped together when discussing the application of the 4916576 Water Tube Bracket. Both engines demand a high level of precision in their cooling systems, and the bracket’s design meets these stringent requirements. On the other hand, the MCRS engines, while also benefiting from the bracket, represent a slightly different application scenario, focusing more on medium-duty performance and reliability.

Role of Part 4916576 Water Tube Bracket in Engine Systems

The part 4916576 Water Tube Bracket is an essential component in the efficient operation of engine systems, particularly in relation to the plumbing and thermostat housing.

Integration with Plumbing

In engine systems, the plumbing network is responsible for circulating coolant throughout the engine to maintain optimal operating temperatures. The Water Tube Bracket, part 4916576, plays a significant role in this network by securely holding water tubes in place. These tubes are integral to the coolant flow path, ensuring that coolant is efficiently directed from the water pump to various parts of the engine, including the cylinder heads and blocks. The bracket’s secure mounting prevents tube displacement or disconnection, which could lead to coolant leaks or inefficient coolant circulation.

Connection to Thermostat Housing

The thermostat housing is a key component that houses the thermostat, which regulates the flow of coolant based on engine temperature. The Water Tube Bracket, part 4916576, often interfaces with the thermostat housing by supporting water tubes that connect to it. This connection ensures a stable and leak-free pathway for coolant to enter and exit the thermostat housing. The bracket’s role in maintaining the structural integrity of this connection is vital for the consistent performance of the thermostat, thereby ensuring that the engine operates within its designed temperature range.

By facilitating secure and efficient connections within the engine’s coolant system, the Water Tube Bracket, part 4916576, contributes to the overall reliability and performance of the engine.

Conclusion

The Water Tube Bracket, part 4916576, is a vital component in the cooling systems of Cummins engines. Its role in supporting water tubes ensures efficient coolant circulation and heat dissipation, contributing to the engine’s performance and longevity. The bracket’s durable construction and precise design make it compatible with various Cummins engines, enhancing the reliability of the cooling system. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩ -

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.