This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

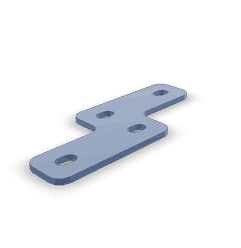

Understanding the Cummins 4917248 Water Tube Bracket

Introduction

Water tube brackets are essential components in the cooling systems of commercial truck engines, ensuring efficient heat dissipation and maintaining optimal engine temperature. Cummins, a leader in the heavy-duty truck parts industry, manufactures high-quality components designed to enhance engine performance and longevity. Among these components is the Cummins 4917248 water tube bracket, a vital part of the engine cooling system.

Basic Concepts Related to Water Tube Brackets

A water tube bracket is a structural component that supports and secures water tubes within the engine cooling system. These brackets are integral to maintaining the proper alignment and positioning of water tubes, which carry coolant between the engine block and the radiator. Typically, water tube brackets are made from durable materials such as cast iron or high-grade steel to withstand the high temperatures and pressures within the engine compartment 1.

Purpose of the Cummins 4917248 Water Tube Bracket

The Cummins 4917248 water tube bracket is specifically designed to support the water tubes in Cummins engines, ensuring they remain in the correct position. This bracket plays a critical role in maintaining the integrity of the cooling system by preventing water tube misalignment, which could lead to coolant leaks and inefficient cooling. Proper installation of the bracket is essential for ensuring efficient engine cooling and preventing overheating.

Functionality and Operation

The Cummins 4917248 operates by securely holding the water tubes in place as they connect the engine block to the radiator. This ensures a consistent flow of coolant, which is vital for dissipating heat generated by the engine. The bracket interacts with other components such as the water tubes, radiator, and engine block, forming a cohesive cooling system. A malfunctioning water tube bracket can lead to coolant leaks, reduced cooling efficiency, and potential engine damage, highlighting the importance of its proper function.

Troubleshooting Common Issues

Common signs of a failing water tube bracket include coolant leaks, unusual engine noises, and overheating. To diagnose bracket issues, mechanics should inspect the bracket for signs of wear, corrosion, or damage. If a problem is detected, the bracket should be replaced promptly to prevent further complications. Troubleshooting involves checking the alignment of the water tubes, ensuring the bracket is securely fastened, and verifying that there are no obstructions or damage to the cooling system components.

Maintenance and Preventive Measures

Regular maintenance of the Cummins 4917248 is essential for ensuring its longevity and performance. Recommended practices include periodic inspections for signs of wear or damage, cleaning the bracket to remove any buildup, and lubricating moving parts to prevent corrosion. Ensuring the bracket remains in optimal condition will contribute to the overall efficiency of the engine cooling system.

Cummins: A Leader in Heavy-Duty Truck Parts

Cummins has established a strong reputation in the industry for manufacturing high-quality, durable truck parts. With a history of innovation and commitment to performance, Cummins continues to lead the way in providing reliable components that enhance engine efficiency and longevity. Their products are designed with durability in mind, ensuring that fleets can operate smoothly and efficiently.

Expert Insights and Best Practices

Industry experts emphasize the importance of water tube brackets in maintaining engine cooling efficiency. Best practices for engineers and mechanics include regular inspections, prompt replacement of worn or damaged brackets, and ensuring proper installation. Real-world examples demonstrate that consistent maintenance of water tube brackets can significantly impact fleet performance, reducing downtime and enhancing engine reliability.

Conclusion

The Cummins 4917248 water tube bracket is a critical component in the engine cooling system, playing a vital role in maintaining efficient engine operation. Regular maintenance and troubleshooting are essential for ensuring the bracket remains in optimal condition. By referring to Cummins resources for detailed specifications and compatibility information, mechanics and engineers can ensure their fleets operate at peak performance.

-

Hilgers, Michael. Commercial Vehicle Technology: The Drivers Cab. Springer Vieweg, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.