This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

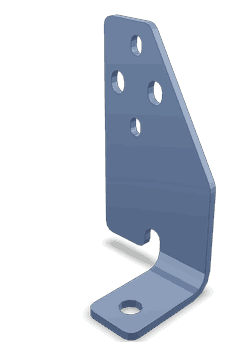

The Water Tube Bracket, identified by part number 4917261, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This bracket plays a role in the engine cooling system of heavy-duty trucks by supporting and aligning water tubes. Its design and function are important for maintaining the structural integrity and alignment of water tubes within the engine.

Purpose and Function

The Water Tube Bracket secures and aligns water tubes in the engine cooling system. By holding the water tubes in place, it ensures efficient coolant flow through the engine, aiding in the dissipation of heat generated during operation. This alignment is important for the consistent performance of the cooling system, which in turn helps maintain optimal engine temperature and performance.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, which contribute to its durability and precision engineering. Manufactured specifically for Cummins engines, it ensures compatibility and seamless integration within the engine system. The bracket’s design allows for easy installation and maintenance, while its material properties resist corrosion and wear, ensuring long-term reliability.

Benefits

Incorporating the Water Tube Bracket into the engine cooling system offers several advantages. It enhances engine performance by ensuring efficient coolant flow, which is vital for maintaining engine temperature within optimal ranges. Improved cooling efficiency leads to better overall engine reliability and longevity. Additionally, the bracket’s durable construction and precise engineering contribute to the long-term reliability of the cooling system, reducing the need for frequent replacements or repairs.

Installation and Maintenance

Proper installation of the Water Tube Bracket is important for its effective function. It should be installed according to the manufacturer’s guidelines, with attention to torque specifications and alignment checks to ensure it is securely fastened and correctly positioned. Regular maintenance checks are recommended to ensure the bracket remains in good condition. This includes inspecting for signs of wear, corrosion, or misalignment, and addressing any issues promptly to maintain optimal performance.

Troubleshooting Common Issues

Common issues associated with the Water Tube Bracket may include misalignment or corrosion. Misalignment can affect the efficiency of the cooling system, leading to potential engine overheating. Regular checks and adjustments can help prevent this issue. Corrosion, while less common due to the bracket’s material properties, can occur over time. Applying a protective coating or replacing the bracket when signs of corrosion are detected can mitigate this problem.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines and components designed for heavy-duty applications, ensuring performance, efficiency, and durability in demanding environments 1.

Water Tube Bracket 4917261 in Cummins Engines

The Water Tube Bracket 4917261 is a component in several Cummins engine models, ensuring the proper alignment and functionality of the water tubes within the engine’s cooling system. This part is integral to maintaining the engine’s operational efficiency and longevity.

KTA38GC CM558 Engines

In the KTA38GC CM558 engines, the Water Tube Bracket 4917261 plays a role in the cooling system. It secures the water tubes in place, preventing any misalignment that could lead to overheating or inefficient cooling. This bracket is designed to withstand the high pressures and temperatures typical of these engines, ensuring durability and reliability under demanding conditions 2.

Grouping of Engines

The Water Tube Bracket 4917261 is also compatible with other Cummins engines within the same series, providing a standardized solution for maintaining the integrity of the cooling system across multiple engine models. This compatibility allows for easier maintenance and repair, as the same part can be used across different engine types, reducing inventory costs and simplifying the supply chain 3.

Role of Part 4917261 Water Tube Bracket in Engine Systems

This Cummins part is an integral component in the integration and functionality of the auxiliary cooling system within various engine systems. This bracket securely mounts the water tubes, which are responsible for directing coolant flow to and from the auxiliary cooling components.

In the auxiliary cooling system, the water tube bracket ensures that the water tubes remain in the correct position and alignment. This alignment is necessary for the efficient transfer of coolant to the auxiliary heat exchanger, which helps in maintaining optimal engine temperatures under varying operational conditions.

The bracket also plays a part in the structural integrity of the cooling system. By providing a stable mounting point for the water tubes, it prevents undue stress on the tubes and connected components, which could otherwise lead to leaks or failures in the cooling system.

Furthermore, the water tube bracket facilitates the connection between the water tubes and other components such as the thermostat housing or the engine block. This connection is vital for the continuous circulation of coolant, which is necessary for dissipating heat generated by the engine.

Conclusion

In summary, the Water Tube Bracket (part number 4917261) is integral to the proper functioning of the auxiliary cooling system, ensuring that coolant is effectively circulated to manage engine temperatures and maintain system reliability. Its robust design, high-quality materials, and precise engineering contribute to the long-term reliability and efficiency of the engine cooling system.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.