This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

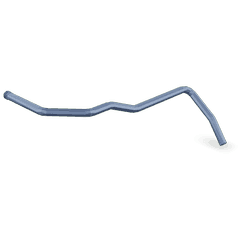

The Cummins 4917465 Water Transfer Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the efficient transfer of coolant within the truck’s cooling system. This part plays a role in maintaining optimal engine temperature, which is vital for the performance and longevity of the engine 1.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit within a truck’s cooling system that allows coolant to circulate between the engine and the radiator. This circulation is important for dissipating heat generated by the engine. By maintaining a consistent coolant flow, the tube helps to regulate engine temperature, preventing overheating and ensuring efficient operation 2.

Purpose of the Cummins 4917465 Water Transfer Tube

The Cummins 4917465 Water Transfer Tube is specifically engineered to enhance the coolant circulation within the truck’s cooling system. It connects key components, allowing coolant to move from the engine to the radiator and back. This continuous flow is important for heat management, as it ensures that the engine does not overheat during operation 3.

Key Features

The Cummins 4917465 Water Transfer Tube is characterized by its robust design and the materials used in its construction. It is made from durable materials that can withstand the high temperatures and pressures within the cooling system. The tube’s design includes precise fittings and connections that ensure a secure and leak-free installation. These features contribute to the tube’s performance and durability in demanding conditions 4.

Benefits

The use of the Cummins 4917465 Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the engine’s thermal management. This results in better engine protection against overheating. Additionally, the tube’s reliable design contributes to increased system reliability, even under strenuous operating conditions 1.

Installation and Compatibility

Proper installation of the Cummins 4917465 Water Transfer Tube is important for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure secure connections and efficient coolant flow. Specific requirements may include the use of compatible gaskets and seals to prevent leaks 2.

Maintenance and Troubleshooting

To ensure the longevity and performance of the Cummins 4917465 Water Transfer Tube, regular maintenance is recommended. This includes checking for signs of wear or damage and ensuring that all connections are secure. Common issues such as leaks or blockages can often be addressed by inspecting the tube and its connections, and making necessary repairs or replacements 3.

Performance in Various Conditions

The Cummins 4917465 Water Transfer Tube is designed to perform effectively under a range of operating conditions. Whether facing extreme temperatures or heavy loads, the tube’s durable construction and efficient design help to maintain consistent coolant flow. Considerations for maximizing its effectiveness may include regular maintenance and ensuring that the cooling system is free from contaminants 4.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a reputation for producing high-quality automotive components. The company has a history of innovation and commitment to excellence in the industry. Cummins’ products, including the 4917465 Water Transfer Tube, are designed with a focus on reliability and performance, reflecting the brand’s dedication to quality 1.

Role of Part 4917465 Water Transfer Tube in Engine Systems

The Water Transfer Tube, identified by part number 4917465, is an integral component in the efficient operation of engine systems, particularly within the auxiliary cooling system. This tube facilitates the movement of coolant between various parts of the engine, ensuring that all components maintain optimal operating temperatures 2.

In the auxiliary cooling system, the Water Transfer Tube connects the main coolant passages to the auxiliary cooler. This setup allows for additional cooling capacity, especially under high-stress conditions or in high-performance applications. The tube ensures that coolant is effectively circulated through the auxiliary cooler, which helps in dissipating excess heat and maintaining stable engine temperatures 3.

Furthermore, the Water Transfer Tube plays a significant role in the overall thermal management of the engine. By providing a dedicated pathway for coolant flow, it helps prevent hotspots and ensures uniform cooling across critical engine components. This consistent coolant flow is essential for the longevity and reliability of the engine, as it reduces the risk of thermal stress and potential damage 4.

Conclusion

The Cummins 4917465 Water Transfer Tube is a critical component in the cooling systems of commercial trucks and various engine models. Its role in facilitating efficient coolant circulation ensures optimal engine temperature management, contributing to the performance and longevity of the engine. Proper installation, regular maintenance, and understanding its function in different engine systems are key to maximizing the benefits of this Cummins part.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ ↩ ↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ ↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ ↩ ↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.