This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4917482 Water Transfer Tube is a critical component in heavy-duty trucks, specifically designed for the QSK60 CM500 and QSK60 CM850 MCRS engines. This part ensures efficient coolant circulation within the engine’s cooling system, contributing to optimal engine temperature regulation and performance 1.

Basic Concepts of Water Transfer Tubes

Water Transfer Tubes are integral to a vehicle’s cooling system, facilitating the movement of coolant between the engine and radiator. This process is essential for dissipating heat generated by the engine, maintaining a stable operating temperature 2.

Purpose of the Cummins 4917482 Water Transfer Tube

This Cummins part ensures efficient coolant circulation in the truck’s cooling system. By facilitating smooth coolant transfer, it prevents engine overheating and ensures operation within the optimal temperature range, enhancing engine efficiency and reliability 3.

Key Features

The 4917482 is characterized by its durable material composition, designed to withstand high temperatures and pressures. Its design elements, including shape and connection points, ensure a secure fit and efficient coolant flow. Unique attributes like reinforced sections or specialized coatings further enhance its resilience in demanding conditions.

Benefits

The benefits of the 4917482 include improved engine efficiency, longevity, and reliability. Efficient coolant circulation maintains optimal engine temperature, leading to enhanced performance and fuel efficiency. Its durable construction reduces the need for frequent replacements, ensuring consistent engine cooling.

Installation and Integration

Installing the 4917482 requires careful consideration of compatibility with specific truck models and proper alignment within the cooling system. Ensuring a secure fit is crucial for effective tube function.

Maintenance and Care

Regular inspection and cleaning of the 4917482 are essential for optimal performance. Flushing the cooling system removes contaminants, and following recommended service intervals ensures the tube and cooling system remain in good condition.

Troubleshooting Common Issues

Common issues with Water Transfer Tubes include leaks, blockages, or damage. Troubleshooting involves inspecting for visible damage, checking alignment and fitting, and ensuring the cooling system is free from contaminants.

Performance in Various Conditions

The 4917482 is designed to perform under extreme temperatures and heavy-duty usage. Regular maintenance and inspection are necessary for optimal performance under these conditions.

Cummins Overview

Cummins Inc. is renowned in the automotive and heavy-duty truck industry for its quality and reliability. The company’s commitment to innovation and excellence is evident in its wide range of products, including the 4917482 Water Transfer Tube.

Role of 4917482 in Engine Systems

Plumbing Systems

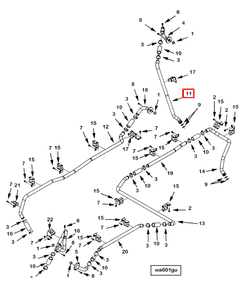

In engine plumbing systems, the 4917482 facilitates coolant movement between engine sections, ensuring optimal operating temperatures. It connects to the water pump and extends to various engine components, providing a consistent pathway for coolant.

Intercooler Water Systems

For engines with intercoolers, the 4917482 is crucial in the intercooler water system. It transfers water to the intercooler, cooling compressed air from the turbocharger before it enters the combustion chamber. This results in more efficient combustion and reduced thermal stress on engine components.

Conclusion

The Cummins 4917482 Water Transfer Tube is a vital component in maintaining engine performance and longevity. Its role in efficient coolant circulation and temperature regulation is crucial for the optimal functioning of heavy-duty truck engines.

-

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.