This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

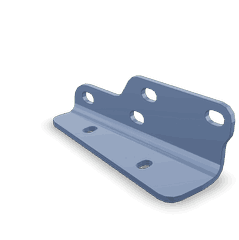

The Cummins 4917678 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its primary function is to store rotational energy and smooth out the power delivery from the engine, contributing to the overall efficiency and performance of the truck.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that uses the principle of rotational inertia to store energy. Within an engine system, it functions by maintaining a consistent rotational speed, which helps in stabilizing the engine’s operation. The flywheel’s role in storing rotational energy allows it to smooth out the power delivery from the engine, ensuring a more consistent and reliable performance 1.

Purpose of the 4917678 Flywheel

The Cummins 4917678 Flywheel is specifically engineered to enhance the operation of commercial trucks. It contributes to engine performance by ensuring smooth power delivery, which is crucial for the efficient operation of the drivetrain. Additionally, it plays a role in improving fuel efficiency by reducing the fluctuations in engine speed, thereby optimizing the engine’s operation. The flywheel also helps in reducing wear on other components by providing a stable rotational force, which is vital for the longevity and reliability of the truck’s drivetrain 2.

Key Features

The Cummins 4917678 Flywheel is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. Its design ensures optimal balance, which is critical for minimizing vibrations and ensuring smooth operation. The weight of the flywheel is carefully calibrated to provide the necessary inertia without adding excessive load to the engine. These features, combined with its construction, make the 4917678 Flywheel a reliable component for commercial truck applications 3.

Benefits

Using the Cummins 4917678 Flywheel offers several benefits. It contributes to improved engine performance by ensuring a smooth and consistent power delivery. This results in enhanced fuel efficiency, as the engine operates more efficiently with reduced fluctuations in speed. Additionally, the flywheel helps in reducing wear on other components, such as the clutch and transmission, by providing a stable rotational force. Its durability and reliability also contribute to the overall reliability of the truck’s drivetrain 4.

Installation Considerations

Proper installation of the Cummins 4917678 Flywheel is crucial for ensuring its optimal performance and longevity. It is important to follow guidelines for alignment and torque specifications to ensure that the flywheel is securely and correctly installed. Any prerequisites or additional components required for installation should be carefully considered and properly installed to ensure the flywheel functions as intended 5.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 4917678 Flywheel include vibration, noise, and failure symptoms. These issues can often be traced back to improper installation, wear and tear, or other mechanical problems. Troubleshooting steps may involve checking the alignment and torque specifications, inspecting for wear or damage, and addressing any underlying mechanical issues that may be contributing to the problem 6.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4917678 Flywheel, regular maintenance is recommended. This includes periodic inspections to check for wear or damage, cleaning to remove any debris or contaminants, and following manufacturer guidelines for when to consider replacement. Proper maintenance not only ensures the flywheel’s performance but also contributes to the overall reliability of the truck’s drivetrain 7.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history and a broad product range, Cummins is renowned for its commitment to quality and innovation in the commercial truck industry. The company’s dedication to excellence is evident in its engine components, including the Cummins 4917678 Flywheel, which is designed to meet the demanding requirements of commercial truck applications 8.

Cummins Flywheel Part 4917678 Compatibility

The Cummins flywheel part number 4917678 is a critical component in the engine’s operation, ensuring smooth power delivery and efficient engine performance. This flywheel is designed to fit seamlessly with several Cummins engine models, enhancing their reliability and performance.

QSK60 Engine

The QSK60 engine, known for its robust design and high power output, benefits from the 4917678 flywheel. This part ensures that the engine’s crankshaft and transmission components work in harmony, providing a stable and reliable power transfer.

CM850 Engine

In the CM850 engine, the 4917678 flywheel plays a pivotal role in maintaining the engine’s balance and smooth operation. This engine, often used in heavy-duty applications, relies on the flywheel to manage the rotational forces effectively, contributing to its durability and efficiency.

MCRS Engine

The MCRS engine, another high-performance model from Cummins, is also compatible with the 4917678 flywheel. This part is engineered to handle the specific demands of the MCRS engine, ensuring optimal performance and longevity.

Grouping of Engines

The QSK60, CM850, and MCRS engines share common design principles and operational requirements, making the 4917678 flywheel a versatile component across these models. This compatibility allows for easier maintenance and part replacement, streamlining the service process for these engines.

Role of Part 4917678 Flywheel in Engine Systems

The 4917678 Flywheel is an integral component in the operation of various engine systems. Its primary function is to store rotational energy and smooth out the power delivery from the engine’s combustion cycles. This stored energy helps maintain engine momentum between power strokes, ensuring consistent operation.

Interaction with Heat Exchanger

In systems where a heat exchanger is employed, the flywheel’s consistent rotational energy aids in maintaining a stable flow of coolant. This stability is essential for efficient heat transfer, ensuring that the engine operates within optimal temperature ranges. The flywheel’s smooth operation reduces fluctuations in engine speed, which can otherwise affect the performance of the heat exchanger.

Contribution to Plumbing Systems

Within the engine’s plumbing system, the flywheel plays a supportive role by providing a steady rotational force. This steadiness is particularly important for components like the water pump, which relies on consistent engine speed to circulate coolant effectively. The flywheel helps minimize pulsations in the plumbing system, leading to more reliable coolant flow and reduced stress on hoses and connections.

Influence on Thermostat Housing

The thermostat housing, which regulates the flow of coolant based on engine temperature, benefits from the flywheel’s smooth operation. Consistent engine speed ensures that the thermostat can open and close at the correct times, maintaining engine temperature stability. The flywheel’s role in providing a uniform power delivery helps prevent abrupt changes in engine speed that could disrupt the thermostat’s function.

Conclusion

The Cummins 4917678 Flywheel enhances the performance and reliability of various engine systems by ensuring smooth and consistent rotational energy. This stability is vital for the efficient operation of components like the heat exchanger, plumbing system, and thermostat housing. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part, contributing to the overall efficiency and longevity of commercial truck engines.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). Service Manual (4021271) for ISBe, ISB, and QSB (Common Rail Fuel System).

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Service Manual (4021271) for ISBe, ISB, and QSB (Common Rail Fuel System).

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.