This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Tube Bracket (4924341) is a component manufactured by Cummins, designed for use in heavy-duty trucks. This bracket supports the water tubes within the engine cooling system, ensuring reliable and efficient engine performance 1.

Function and Operation

The Water Tube Bracket operates within the engine cooling system by maintaining the structural integrity and alignment of the water tubes. It secures the water tubes in place, allowing for the efficient circulation of coolant throughout the engine. This circulation is vital for dissipating heat generated during engine operation, thereby contributing to the overall cooling efficiency of the engine 2.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the harsh conditions within an engine compartment. Its design includes precise mounting points and secure attachment mechanisms, which facilitate easy installation and reliable performance. Additionally, the bracket may feature corrosion-resistant coatings or treatments, enhancing its longevity and performance in various operating environments 3.

Benefits

The use of the Water Tube Bracket offers several advantages. It contributes to improved engine efficiency by ensuring the proper alignment and support of water tubes, which is crucial for effective coolant flow. The bracket’s durable construction enhances the overall reliability of the engine cooling system, reducing the likelihood of coolant leaks or system failures. Furthermore, its design and material composition support long-term performance, contributing to the engine’s durability and operational reliability 4.

Installation Process

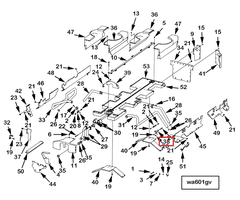

Installing the Water Tube Bracket requires careful attention to ensure proper placement and secure attachment. The process involves identifying the correct location within the engine compartment, aligning the bracket with the mounting points, and using the appropriate tools to fasten it in place. It is important to follow manufacturer guidelines for torque specifications and attachment methods to ensure the bracket is installed correctly and functions as intended 5.

Maintenance and Troubleshooting

Regular maintenance of the Water Tube Bracket includes inspecting it for signs of wear, corrosion, or damage. Ensuring that the bracket remains securely attached and that the water tubes are properly aligned are key maintenance tasks. Common issues may include loose fasteners or corrosion, which can be addressed by tightening or replacing affected components as necessary. Regular checks and timely maintenance can help prevent more significant problems and ensure the continued efficiency of the engine cooling system 6.

Safety Considerations

When working with the Water Tube Bracket, it is important to observe safety precautions to protect against injury and ensure the component’s proper function. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for installation and maintenance. Additionally, being aware of the potential for sharp edges or hot surfaces within the engine compartment can help prevent accidents during handling and installation 7.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications 8.

Role of Water Tube Bracket in Engine Systems

The Water Tube Bracket (4924341) is an essential component in various engine systems, facilitating the secure attachment and alignment of water tubes within the system. Its role is significant in ensuring the efficient operation of the plumbing, aftercooler water system, and auxiliary cooling components.

Plumbing

In the plumbing system, the Water Tube Bracket ensures that water tubes are correctly positioned and supported. This is important for maintaining the integrity of the water flow path, preventing leaks, and ensuring that water reaches all necessary components without obstruction. The bracket’s secure hold on the tubes helps in withstanding the pressure and vibrations typical in engine environments 9.

Aftercooler Water System

For the aftercooler water system, the Water Tube Bracket plays a key role in maintaining the structural stability of the water tubes that circulate cooling water through the aftercooler. This system relies on consistent and reliable water flow to effectively reduce the temperature of compressed air, enhancing engine performance and efficiency. The bracket ensures that the tubes remain in optimal alignment, facilitating uninterrupted water circulation 10.

Auxiliary Cooling

In auxiliary cooling systems, the Water Tube Bracket supports additional water tubes that may be used for cooling specific engine components or for supplementary cooling functions. This can include cooling jackets around cylinders, turbochargers, or other heat-generating parts. The bracket’s function here is to ensure that these auxiliary cooling tubes are firmly in place, allowing for effective heat dissipation and maintaining the engine’s operational temperature within safe limits 11.

Conclusion

The Water Tube Bracket (4924341) is integral to the reliable and efficient operation of engine systems, ensuring that water tubes are securely held in place and properly aligned to support the flow of cooling water where it is needed most. Its durable construction, precise design, and role in maintaining the integrity of the cooling system make it a critical component in heavy-duty truck engines.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩ -

Cummins Inc. Operation and Maintenance Manual for L9 CM2350 L129C, Bulletin Number 5579688.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.