This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

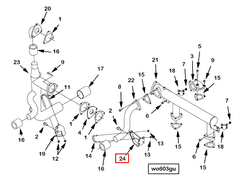

The Water Tube Bracket (Part #4927852) manufactured by Cummins is a component designed to support the efficient operation of the cooling system in heavy-duty trucks. This part contributes to maintaining engine efficiency and performance by ensuring proper coolant circulation and thermal management 1.

Basic Concepts of Water Tube Brackets

A Water Tube Bracket is a structural component that supports and secures the water tubes within the engine cooling system. Its function is to facilitate the circulation of coolant through the engine, aiding in the dissipation of heat generated during operation. This contributes to the overall thermal management of the engine, helping to maintain optimal operating temperatures 2.

Purpose of the Water Tube Bracket

This Cummins part plays a specific role in the operation of a truck by supporting the water tubes that carry coolant throughout the engine. This ensures that coolant is effectively circulated, which is vital for maintaining the engine at an optimal temperature. Proper coolant circulation helps prevent overheating, which can lead to engine damage and reduced performance 3.

Key Features

The 4927852 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design of the bracket is engineered to provide a secure fit for the water tubes, minimizing the risk of leaks and ensuring efficient coolant flow. Additionally, the bracket may include features such as reinforced mounting points and precise alignment guides to facilitate easy and accurate installation 4.

Benefits

Using this part offers several benefits. It contributes to improved engine cooling efficiency by ensuring secure and stable water tube connections. This enhances the reliability of the cooling system, potentially leading to extended engine lifespan. The robust construction of the bracket also adds to the overall durability of the cooling system, reducing the likelihood of maintenance issues 5.

Installation Process

Installing the Water Tube Bracket involves several steps to ensure correct fitting and functionality. Begin by ensuring the engine is cool and the cooling system is depressurized. Remove the old bracket if replacing, and clean the mounting area. Position the new bracket over the water tubes and secure it in place using the provided fasteners. Ensure all connections are tight and there are no gaps that could lead to leaks. Finally, refill the cooling system with the appropriate coolant and check for any leaks after the engine has reached operating temperature 6.

Troubleshooting Common Issues

Common issues with the Water Tube Bracket may include leaks or corrosion. To troubleshoot these problems, first, inspect the bracket and water tubes for any signs of damage or wear. Check the connections for tightness and ensure there are no gaps that could allow coolant to escape. If corrosion is present, it may be necessary to clean the affected areas or replace the bracket to prevent further issues. Regular inspections can help identify potential problems before they lead to more significant issues 7.

Maintenance Tips

To maintain the 4927852, regular inspection procedures should be followed. Check the bracket and water tubes for signs of wear, corrosion, or leaks during routine maintenance checks. Clean the bracket as needed to remove any buildup that could affect its performance. If any damage or significant wear is detected, consider replacing the bracket to ensure the continued efficiency of the cooling system 8.

Compatibility and Application

The 4927852 is designed for use with specific Cummins engine models and is applicable in various types of heavy-duty trucks. Its compatibility ensures that it fits securely and functions effectively within the intended engine systems 9.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins serves the automotive and heavy-duty truck industries, among others. The company is known for its robust product offerings and dedication to advancing technology in the power generation sector 10.

Water Tube Bracket 4927852 Compatibility with Cummins Engines

The Water Tube Bracket 4927852, manufactured by Cummins, is a component in the engine cooling system. This part is designed to securely hold water tubes in place, ensuring efficient heat transfer and maintaining optimal engine temperatures.

QSK60 and CM850 Engines

The Water Tube Bracket 4927852 is compatible with the QSK60 and CM850 engines. These engines are part of Cummins’ high-performance lineup, often used in heavy-duty applications such as marine and industrial settings. The bracket’s robust design ensures it can withstand the demanding conditions these engines operate under, providing reliable support for the water tubes 11.

MCRS Engines

The MCRS engines also benefit from the Water Tube Bracket 4927852. These engines are typically used in military and defense applications, where durability and reliability are paramount. The bracket’s precision engineering ensures it fits seamlessly into the MCRS engine’s cooling system, contributing to the engine’s overall performance and longevity 12.

Grouping of Engines

The QSK60, CM850, and MCRS engines share a common requirement for efficient cooling systems, making the Water Tube Bracket 4927852 a versatile component across these engine types. Its compatibility with these engines underscores its importance in maintaining the integrity of the cooling system, ensuring that the engines operate at peak efficiency 13.

Role of Part 4927852 Water Tube Bracket in Engine Systems

The 4927852 Water Tube Bracket is a component in the integration and functionality of various engine systems. Its primary role is to securely hold the water tube in place, ensuring a stable connection between the water outlet and other critical components of the cooling system.

When installed, the Water Tube Bracket facilitates the proper alignment and attachment of the water tube to the water outlet. This connection is vital for maintaining the integrity of the coolant flow path, which is necessary for efficient heat dissipation from the engine. The bracket’s design allows for precise positioning, reducing the risk of leaks and ensuring that the water tube remains firmly in place under operational conditions.

Additionally, the Water Tube Bracket contributes to the overall structural stability of the cooling system. By providing a robust mounting point for the water tube, it helps to withstand the vibrations and stresses that occur during engine operation. This stability is important for the longevity and reliability of the cooling system components.

In summary, the 4927852 Water Tube Bracket plays a role in the effective functioning of the engine’s cooling system by ensuring secure and stable connections between the water tube and the water outlet 14.

Conclusion

The Water Tube Bracket (Part #4927852) is a vital component in the cooling systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its design and construction ensure efficient coolant circulation, which is critical for maintaining optimal engine temperatures and preventing overheating. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall reliability and performance of the engine.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.