This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Water Bypass Tube 4943259, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the engine manufacturing industry, produces a range of parts that contribute to the efficient operation of engines under demanding conditions. This part is significant in the context of heavy-duty truck engines as it plays a role in the engine’s cooling system, helping to maintain optimal operating temperatures 1.

Basic Concepts of Water Bypass Tubes

A Water Bypass Tube is a component found in engine cooling systems. Its general function is to regulate the flow of coolant within the engine. By controlling the coolant flow, the tube helps maintain the engine’s temperature within a specified range, which is important for efficient engine operation and longevity. The tube operates by allowing coolant to bypass the thermostat under certain conditions, ensuring that the engine does not overheat 2.

Purpose of the 4943259 Water Bypass Tube

This Cummins part is specifically designed to regulate coolant flow in truck engines. It plays a role in the engine’s cooling system by providing an alternative path for coolant when the thermostat is closed. This function is vital during engine warm-up and under high-load conditions, where maintaining optimal engine temperature is particularly important 3.

Key Features

The 4943259 is constructed from durable materials that can withstand the high temperatures and pressures within an engine cooling system. Its design includes precise engineering to ensure efficient coolant flow and reliable operation. Unique characteristics of this tube may include enhanced sealing mechanisms to prevent leaks and a robust construction to endure the rigors of heavy-duty use 4.

Benefits

The advantages provided by the Water Bypass Tube include improved engine efficiency through consistent temperature regulation. This consistent regulation contributes to the engine’s longevity by reducing thermal stress. Additionally, the tube’s reliable performance under various operating conditions enhances the overall reliability of the engine cooling system 1.

Installation Process

Installing this part requires careful attention to ensure correct fitting and function. Preparatory steps include ensuring the engine is cool and the cooling system is drained to a safe level. Tools required may include wrenches and sealants. Best practices during installation involve following the manufacturer’s guidelines for torque specifications and ensuring all connections are secure and leak-free 2.

Troubleshooting Common Issues

Common problems associated with Water Bypass Tubes include leaks or blockages. Troubleshooting methods to diagnose these issues involve inspecting the tube and connections for signs of wear or damage. Resolving these issues may require cleaning or replacing the tube, depending on the severity of the problem 3.

Maintenance Tips

Regular maintenance of the 4943259 includes periodic inspections for signs of wear or damage. Cleaning procedures may involve flushing the cooling system to remove any debris that could affect the tube’s performance. Replacement should be considered if the tube shows significant signs of wear or if coolant leaks are detected 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the heavy-duty truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications.

Water Bypass Tube (Part 4943259) Compatibility with Cummins Engines

This part is a critical component in the cooling system of various Cummins engines. It is designed to manage the flow of coolant, ensuring efficient thermal management and preventing overheating. Below is a detailed description of the compatibility of this part with the listed Cummins engines.

B4.5 Series Engines

The Water Bypass Tube is compatible with the following B4.5 series engines:

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

These engines benefit from the precise control of coolant flow provided by the Water Bypass Tube, ensuring optimal engine performance and longevity.

D4.0 Series Engines

The Water Bypass Tube is also compatible with the following D4.0 series engine:

- D4.0 CM2620 D103B

This engine relies on the Water Bypass Tube to maintain efficient thermal management, crucial for its operational efficiency.

F3.8 Series Engines

The Water Bypass Tube fits the following F3.8 series engines:

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 F102

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- QSF3.8 CM2350 F107

These engines utilize the Water Bypass Tube to regulate coolant flow, ensuring that the engine operates within its optimal temperature range.

F4.5 Series Engines

The Water Bypass Tube is compatible with the following F4.5 series engines:

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

These engines require the Water Bypass Tube to maintain efficient thermal management, which is essential for their performance and durability.

ISF4.5 Series Engine

The Water Bypass Tube fits the following ISF4.5 series engine:

- ISF4.5 CM2220 F123

This engine benefits from the Water Bypass Tube’s role in managing coolant flow, ensuring that the engine operates efficiently and reliably.

QSF3.8 Series Engines

The Water Bypass Tube is compatible with the following QSF3.8 series engines:

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

These engines rely on the Water Bypass Tube to maintain efficient thermal management, which is crucial for their performance and longevity.

By ensuring that the Water Bypass Tube is correctly installed and functioning, these engines can maintain optimal operating temperatures, leading to improved performance and extended service life.

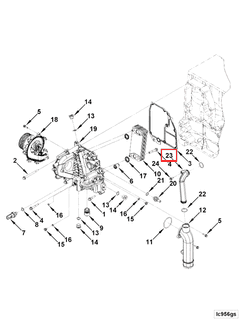

Role of Part 4943259 Water Bypass Tube in Engine Systems

This part is an essential component in the thermal management system of an engine. It is strategically positioned to facilitate the efficient circulation of coolant, ensuring optimal engine performance and longevity.

Integration with Engine Oil Cooler

The Water Bypass Tube works in conjunction with the Engine Oil Cooler to regulate the temperature of the engine oil. As the coolant flows through the bypass tube, it either directs the coolant directly to the oil cooler or bypasses it, depending on the engine’s thermal needs. This dynamic flow management helps maintain the oil at an ideal temperature, enhancing lubrication and reducing wear on engine components 1.

Interaction with Lubricating Oil Cooler Module

In systems equipped with a Lubricating Oil Cooler Module, the Water Bypass Tube plays a pivotal role. It ensures that the coolant reaching the module is at the appropriate temperature, allowing for effective heat exchange between the coolant and the lubricating oil. This interaction is vital for dissipating excess heat generated during engine operation, thereby protecting the oil from degradation and ensuring consistent viscosity for optimal lubrication 2.

Connection to Water Inlet

The Water Bypass Tube is directly connected to the Water Inlet, which is the entry point for coolant into the engine’s cooling system. This connection allows for seamless integration into the coolant circulation path. The bypass tube’s design enables it to modulate the flow of coolant, ensuring that the engine receives the right amount of cooling at any given time. This is particularly important during cold starts or when the engine is under heavy load, as it helps achieve thermal stability more rapidly 3.

Conclusion

In summary, the 4943259 Water Bypass Tube is a key component in the thermal management of engine systems. Its role in regulating coolant flow to critical components like the Engine Oil Cooler and Lubricating Oil Cooler Module, as well as its connection to the Water Inlet, underscores its importance in maintaining engine efficiency and reliability 4.

-

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ ↩ ↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ ↩ ↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ ↩ ↩ -

ElGindy, Moustafa, and Zeinab ElSayegh. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.