This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

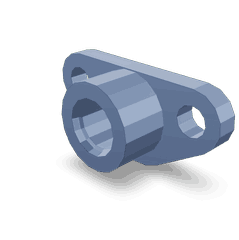

The Cummins 4951905 Water Transfer Connection is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its purpose is to ensure that the engine maintains optimal operating temperatures, thereby contributing to the overall performance and longevity of the vehicle 3.

Basic Concepts of Water Transfer Connection

Water transfer connections in commercial trucks are integral to the cooling system. They enable the circulation of coolant between various components, such as the engine block, radiator, and other heat exchangers. This circulation helps dissipate heat generated during engine operation, preventing overheating and potential damage 1.

Purpose of the 4951905 Water Transfer Connection

The 4951905 Water Transfer Connection plays a specific role in the truck’s cooling system by providing a conduit for coolant flow. It ensures that coolant is efficiently transferred from the engine to the radiator and back, maintaining a consistent temperature. This component is designed to handle the pressures and temperatures within the cooling system, ensuring reliable performance 3.

Key Features

The 4951905 Water Transfer Connection is characterized by several key features that enhance its performance. Its design incorporates robust materials that can withstand high temperatures and pressures. The connection is engineered to provide a secure fit, minimizing the risk of leaks. Additionally, it may include features such as integrated gaskets or O-rings to ensure a tight seal 2.

Benefits

The advantages of the 4951905 Water Transfer Connection include improved coolant flow, which contributes to more effective engine cooling. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Enhanced coolant circulation can also contribute to overall engine efficiency, potentially leading to better fuel economy and reduced wear on engine components 3.

Installation Process

Installing the 4951905 Water Transfer Connection involves several steps to ensure proper fitting and function. Begin by draining the coolant system to prevent spills. Locate the connection point on the engine and clean the area to remove any debris. Apply a compatible sealant to the threads of the connection, if necessary. Carefully thread the water transfer connection into place, ensuring it is snug but not overtightened. Refill the coolant system and check for leaks 2.

Common Issues and Troubleshooting

Common problems with water transfer connections can include leaks, blockages, or corrosion. To troubleshoot these issues, first, inspect the connection for visible signs of damage or wear. Check for leaks around the connection point and ensure that the seals are intact. If a blockage is suspected, flush the cooling system to remove any debris. Corrosion can be addressed by replacing the affected components and ensuring that the coolant is properly maintained 1.

Maintenance Tips

To ensure the longevity and optimal performance of the 4951905 Water Transfer Connection, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, ensuring that seals and gaskets are in good condition, and maintaining the proper coolant level and quality. Following the manufacturer’s guidelines for coolant replacement intervals can also contribute to the component’s durability 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. Their product range includes engines and components designed to meet the demanding requirements of heavy-duty applications 3.

Cummins Engine Part 4951905: Water Transfer Connection

The Cummins part 4951905, identified as a Water Transfer Connection, is a critical component in the cooling systems of various Cummins engines. This part is integral to the efficient operation of the engine by ensuring proper water flow between different parts of the cooling system 3.

K19 Engines

In the K19 engines, the Water Transfer Connection part 4951905 plays a crucial role in maintaining the optimal temperature of the engine. This part facilitates the transfer of coolant between the engine block and the radiator, ensuring that the engine operates within its specified temperature range 3.

QSK19 CM2350 and QSK19 CM500

For the QSK19 CM2350 and QSK19 CM500 engines, the Water Transfer Connection part 4951905 is essential for the seamless transfer of coolant. These engines, known for their robust performance, rely on this part to maintain consistent coolant flow, which is vital for preventing overheating and ensuring longevity 3.

QSK19 CM850 MCRS

The QSK19 CM850 MCRS engine also benefits from the Water Transfer Connection part 4951905. This part ensures that the coolant is efficiently circulated throughout the engine, which is critical for maintaining the engine’s performance and reliability, especially in demanding applications 3.

Grouping of Engines

The engines K19, QSK19 CM2350, QSK19 CM500, and QSK19 CM850 MCRS all share a common requirement for the Water Transfer Connection part 4951905. This part is designed to fit seamlessly into the cooling systems of these engines, ensuring that they operate efficiently and reliably. The consistent use of this part across these engines highlights its importance in maintaining the integrity of the cooling system 3.

Role of Part 4951905 Water Transfer Connection in Engine Systems

The part 4951905 Water Transfer Connection is integral to the efficient operation of several engine components. Its primary function is to facilitate the seamless transfer of water between various parts of the engine system, ensuring optimal performance and longevity 3.

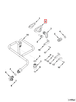

Interaction with the Compressor

In compressor systems, the 4951905 Water Transfer Connection plays a significant role in managing the flow of water to and from the compressor. This is essential for maintaining the compressor’s temperature within safe operating limits. The connection ensures that the compressor receives a consistent supply of coolant, which is vital for its efficient operation and protection against overheating 3.

Air and Plumbing Systems

Within the air and plumbing systems of an engine, the 4951905 Water Transfer Connection acts as a bridge, allowing for the smooth transit of water through these components. This is particularly important in systems where air cooling is supplemented by water cooling. The connection helps in balancing the thermal loads across different parts of the engine, thereby enhancing overall system efficiency 1.

Compressor Coolant Management

The management of compressor coolant is another area where the 4951905 Water Transfer Connection is indispensable. It ensures that the coolant is distributed evenly throughout the compressor, preventing hotspots and ensuring uniform cooling. This not only protects the compressor but also contributes to the stability and reliability of the entire engine system 3.

Water Inlet Tube Mounting

Finally, the connection is crucial in the mounting of the water inlet tube. It provides a secure and leak-proof interface between the water inlet tube and the engine block or other components. This ensures that water enters the system at the correct pressure and flow rate, which is essential for the effective cooling of engine components 2.

Conclusion

The 4951905 Water Transfer Connection is a key component in the intricate network of an engine’s cooling system. Its role in facilitating the efficient transfer of water across various engine components is fundamental to the engine’s performance, durability, and reliability 3.

-

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ ↩ ↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ ↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.