This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

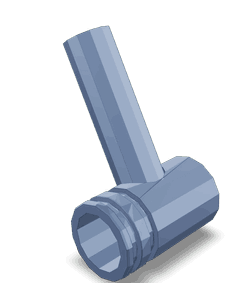

The Water Transfer Connection 4956470, manufactured by Cummins, is designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. This part is integral to maintaining optimal engine temperature, ensuring the engine operates within safe thermal limits 1. Cummins is known for producing reliable and high-quality components that enhance the performance and durability of truck engines 2.

Basic Concepts of Water Transfer Connection

A Water Transfer Connection allows for the circulation of coolant between different parts of a truck’s cooling system. Its function is to ensure that coolant is evenly distributed, which helps in dissipating heat generated by the engine. This process is vital for maintaining engine temperature within a specified range, which is important for engine longevity and performance 3.

Purpose of the 4956470 Water Transfer Connection

The 4956470 Water Transfer Connection serves to connect various components within the truck’s cooling system, facilitating the smooth flow of coolant. Its role is to ensure that coolant reaches all necessary areas of the engine, promoting uniform cooling. This connection enhances the efficiency of heat dissipation, which in turn supports the engine’s performance and reliability 4.

Key Features

The 4956470 Water Transfer Connection is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design of this component includes precise fittings and seals that prevent leaks, ensuring a secure connection within the cooling system. Additionally, its unique characteristics, such as the ability to withstand high pressure and temperature fluctuations, make it a reliable choice for commercial truck applications 5.

Benefits

The benefits of using the 4956470 Water Transfer Connection include improved cooling efficiency, which contributes to better engine performance and longevity. Its durable construction leads to reduced maintenance needs and potential cost savings for fleet operators. By ensuring a consistent and efficient flow of coolant, this component plays a role in preventing engine overheating, which can lead to costly repairs and downtime. Furthermore, its reliable performance under various operating conditions makes it a valuable asset for maintaining the overall efficiency of the truck’s cooling system 6.

Installation Process

Installing the 4956470 Water Transfer Connection requires careful attention to detail to ensure a secure and effective fit. The process involves preparing the connection points, applying the appropriate sealant to prevent leaks, and using the correct tools to tighten the connections without over-torquing. It is important to follow the manufacturer’s guidelines for installation to ensure compatibility and performance. Best practices include inspecting the connection for any signs of damage before installation and ensuring that all components are clean and free of debris 7.

Troubleshooting Common Issues

Common issues associated with Water Transfer Connections, such as leaks or blockages, can often be traced back to improper installation or wear and tear. Troubleshooting these problems involves inspecting the connection for signs of damage, checking the seals for integrity, and ensuring that the connection is properly tightened. In cases of blockages, it may be necessary to flush the cooling system to remove any debris that could be obstructing the flow of coolant. Regular inspections and maintenance can help in identifying and resolving these issues before they lead to more significant problems 8.

Maintenance Tips

Regular maintenance of the 4956470 Water Transfer Connection is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or leaks, and cleaning the connection points to remove any buildup that could impede coolant flow. It is also important to follow the manufacturer’s recommendations for inspection intervals and to replace the component if any significant wear or damage is detected. Keeping the cooling system clean and free of contaminants will also contribute to the efficient operation of the Water Transfer Connection 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and durability of commercial vehicles. Cummins’ commitment to excellence is reflected in the design and manufacturing of components like the 4956470 Water Transfer Connection, ensuring that fleet operators can rely on their equipment for consistent and reliable performance 10.

Role of Part 4956470 Water Transfer Connection in Engine Systems

The 4956470 Water Transfer Connection is integral to the efficient operation of engine systems, particularly in ensuring the proper circulation of coolant. This component facilitates the connection between the manifold and the water system, enabling a seamless flow of coolant throughout the engine.

Interaction with the Manifold

The manifold is a key component in the engine system, responsible for distributing air or fluid to different parts of the engine. The Water Transfer Connection interfaces directly with the manifold to ensure that coolant is effectively channeled to areas requiring temperature regulation. This connection helps maintain optimal engine temperature by allowing coolant to reach the manifold and subsequently be distributed to critical engine components 11.

Integration with the Water System

The water system within an engine is designed to manage the temperature of the engine by circulating coolant. The Water Transfer Connection plays a significant role in this system by providing a reliable link between various water passages and the manifold. This ensures that coolant is consistently circulated, preventing overheating and enhancing the overall performance and longevity of the engine 12.

Conclusion

In summary, the 4956470 Water Transfer Connection is essential for maintaining the integrity of the coolant flow within engine systems. Its proper installation and function are necessary for the effective operation of both the manifold and the water system, contributing to the engine’s stability and efficiency.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩ -

Richard Viskup, Diesel and Gasoline Engines, IntechOpen, 2020.

↩ -

Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Wiley-ISTE, 2014.

↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak, Critical Component Wear in Heavy Duty Engines, John Wiley & Sons, 2011.

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩ -

Cummins Inc., X12 CM2350 X144C Service Manual (5659745).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.