This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

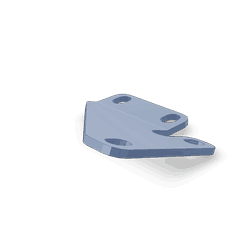

The Water Tube Bracket, identified by part number 4959403, is a component manufactured by Cummins, a leading name in the commercial truck industry. This bracket plays a role in the cooling systems of heavy-duty truck engines. Its design and functionality are tailored to meet the demanding requirements of commercial trucking, ensuring efficient engine operation under various conditions.

Function and Operation

This Cummins part serves a function within the engine’s cooling system. It provides structural support to the water tubes, which are responsible for circulating coolant throughout the engine. By securing the water tubes in place, the bracket helps maintain the integrity of the cooling system, ensuring that coolant flows efficiently to regulate engine temperature. This role is particularly important in heavy-duty applications, where engines operate under high loads and temperatures.

Key Features

The Water Tube Bracket is engineered with several key features that enhance its performance and durability. It is typically made from high-strength materials, such as cast iron or steel, to withstand the rigors of heavy-duty use. The design of the bracket includes precise mounting points and alignment features to ensure a secure fit and proper function within the engine assembly. Additionally, the bracket may incorporate corrosion-resistant coatings or treatments to extend its service life in harsh operating environments.

Benefits

Incorporating the Water Tube Bracket into an engine’s cooling system offers several advantages. It contributes to improved engine efficiency by ensuring that the cooling system operates as intended, which can lead to better overall performance and fuel economy. The bracket’s robust construction and secure mounting also enhance the cooling system’s reliability, reducing the risk of failures that could lead to engine overheating or damage. Furthermore, the use of high-quality materials and precise engineering in the bracket’s design supports its durability and longevity, providing value to fleet operators and maintenance professionals.

Installation and Compatibility

Proper installation of the Water Tube Bracket is crucial for its effective function within the engine’s cooling system. Installation guidelines typically include ensuring the bracket is correctly aligned with the engine’s mounting points and that all fasteners are securely tightened to the manufacturer’s specifications. Compatibility with various Cummins engine models and other relevant truck makes and models is an important consideration, ensuring that the bracket fits and functions as intended across a range of applications.

Maintenance and Troubleshooting

Routine maintenance of the Water Tube Bracket is relatively straightforward but important for ensuring its optimal performance. Regular inspections for signs of wear, corrosion, or damage are recommended, along with checking the tightness of all fasteners. Common issues that may arise with the bracket include corrosion due to exposure to coolant or environmental factors, and mechanical wear from vibrations or thermal cycling. Troubleshooting steps may involve cleaning or replacing corroded components, tightening loose fasteners, or, in more severe cases, replacing the bracket to restore the cooling system’s integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and customer satisfaction in the commercial truck industry. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its extensive product portfolio and the performance of its components, like the Water Tube Bracket 1.

Compatibility with Cummins Engines

This part is a critical component in the engine cooling system. It is designed to securely hold water tubes in place, ensuring efficient heat transfer and maintaining optimal engine temperature.

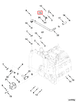

QSK19 and CM850 Engines

The QSK19 and CM850 engines, both part of Cummins’ QSK series, are high-performance engines designed for heavy-duty applications. The Water Tube Bracket fits seamlessly into these engines, providing a robust mounting solution that withstands the rigors of demanding environments. Its precision engineering ensures that the water tubes remain aligned and secure, contributing to the overall reliability and longevity of the engine.

MCRS Engines

The MCRS engines, another variant within Cummins’ lineup, are engineered for marine applications. The Water Tube Bracket is specifically designed to meet the unique requirements of these marine engines. Its durability and resistance to corrosion make it an ideal choice for environments where exposure to saltwater and other harsh conditions is common. This bracket ensures that the water tubes are properly positioned, facilitating efficient cooling and protecting the engine from overheating.

Grouping of Engines

The QSK19, CM850, and MCRS engines share common design principles and engineering standards, which allows the Water Tube Bracket to be used across these models. This compatibility simplifies maintenance and repair processes, as technicians can use a single part for multiple engine types, reducing inventory costs and ensuring consistent performance.

Role of Part 4959403 in Engine Systems

This Cummins part is an essential component in the integration and functionality of various engine systems, particularly in the context of plumbing and aftercooler water systems.

Integration with Plumbing Systems

In plumbing systems associated with engine operations, the Water Tube Bracket secures and supports water tubes that facilitate the flow of coolant or water. This bracket ensures that the tubes are held firmly in place, minimizing the risk of vibrations or movements that could lead to leaks or inefficiencies in the coolant flow. Its role is significant in maintaining the structural integrity of the plumbing system, allowing for consistent and reliable coolant distribution throughout the engine.

Function in Aftercooler Water Systems

In aftercooler water systems, the Water Tube Bracket plays a key role in supporting the water tubes that are integral to the cooling process of compressed air. After the air has been compressed, it is typically very hot, and the aftercooler is designed to reduce its temperature before it enters the engine. The Water Tube Bracket ensures that the water tubes within the aftercooler are properly aligned and secured. This alignment is vital for the efficient transfer of heat from the compressed air to the water, enhancing the overall performance and efficiency of the engine.

By securing the water tubes, the Water Tube Bracket contributes to the stability and effectiveness of both the plumbing and aftercooler water systems. It ensures that these systems operate smoothly, with minimal risk of component failure or performance degradation.

Conclusion

The Water Tube Bracket (Part #4959403) by Cummins is a testament to the company’s dedication to providing reliable and efficient solutions for the commercial trucking sector. Its role in the engine cooling system, combined with its durable construction and precise engineering, underscores the value of using genuine Cummins parts for optimal engine performance and longevity 23.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.