This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

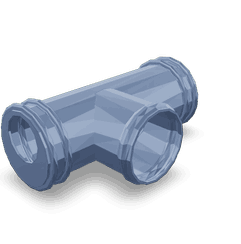

The Water Transfer Tube (Part #4970561) by Cummins is a component designed to facilitate the efficient operation of heavy-duty trucks. Its purpose is to ensure the proper circulation of coolant within the engine cooling system, which is vital for maintaining optimal engine temperature and performance 1.

Basic Concepts and Functionality

The Water Transfer Tube operates on the fundamental principle of fluid dynamics within the engine cooling system. It plays a role in the system by directing the flow of coolant from the engine block to the radiator and back. This circulation helps dissipate heat generated by the engine, ensuring that the engine operates within its designed temperature range 2.

Purpose of the Water Transfer Tube

The Water Transfer Tube is integral to the operation of a truck by maintaining the engine’s temperature. It ensures that coolant is efficiently circulated throughout the engine, which helps prevent overheating. This component contributes to the engine’s longevity and performance by ensuring that all parts of the engine are evenly cooled 3.

Key Features

The Water Transfer Tube is characterized by its durable construction and precise engineering. It is designed to withstand the high pressures and temperatures within the engine cooling system. Its compatibility with Cummins engines ensures that it integrates seamlessly into the system, providing reliable performance 4.

Benefits

The advantages of the Water Transfer Tube include improved engine performance due to consistent cooling. It enhances the reliability of the engine by ensuring that coolant is effectively circulated, reducing the risk of overheating. This component contributes to the overall efficiency and durability of the engine 5.

Installation and Integration

For the proper installation of the Water Transfer Tube, it is important to follow manufacturer guidelines. This includes ensuring that the cooling system is clean and free of debris before installation. Careful attention to the alignment and sealing of the tube within the system is necessary to prevent leaks and ensure efficient coolant flow 6.

Troubleshooting and Maintenance

Common issues with the Water Transfer Tube may include leaks or blockages, which can affect the efficiency of the cooling system. Regular inspection and maintenance, such as checking for signs of wear or damage, can help identify potential problems early. Ensuring that the cooling system is properly maintained can contribute to the longevity and performance of the Water Transfer Tube 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations 8.

Compatibility with Cummins Engines

The Water Transfer Tube (part 4970561) is a critical component in the cooling system of various Cummins engines, ensuring efficient heat transfer and maintaining optimal engine temperature. This part is designed to fit seamlessly within the engine architecture, providing a reliable pathway for coolant circulation.

KTA19GC CM558 Engines

The KTA19GC CM558 engine series is known for its robust performance and reliability in heavy-duty applications. The Water Transfer Tube (part 4970561) is specifically engineered to integrate with the cooling system of these engines, facilitating the transfer of coolant between the engine block and the radiator. This ensures that the engine operates within its optimal temperature range, enhancing longevity and performance 9.

Grouping of Engines

In the broader context, the Water Transfer Tube (part 4970561) is compatible with a range of Cummins engines that share similar design principles in their cooling systems. This part is meticulously crafted to meet the stringent requirements of these engines, ensuring a perfect fit and reliable operation. The compatibility extends to various engine models, providing a versatile solution for maintaining efficient cooling across different engine types 10.

Role of Part 4970561 Water Transfer Tube in Engine Systems

The part 4970561 Water Transfer Tube is an essential component in the cooling system of engine assemblies. It facilitates the movement of coolant between the manifold and the water pump, ensuring efficient heat dissipation from the engine block and cylinder heads.

Interaction with the Manifold

The Water Transfer Tube connects directly to the engine manifold, which is responsible for distributing the air-fuel mixture to the engine’s cylinders. As the engine operates, it generates significant heat. The manifold, being in close proximity to the combustion chambers, absorbs a portion of this heat. The Water Transfer Tube plays a significant role here by channeling coolant to and from the manifold. This helps in maintaining optimal temperatures, preventing overheating, and ensuring the manifold functions correctly without warping or cracking 11.

Connection to the Water Pump

On the other end, the Water Transfer Tube is linked to the water pump, a component that circulates coolant throughout the engine system. The water pump draws coolant from the radiator, where it has been cooled, and pushes it through the engine block, cylinder heads, and other critical components before returning it to the radiator for cooling. The Water Transfer Tube ensures a seamless flow of coolant from the water pump to the manifold and back, maintaining a consistent coolant level and pressure within the system 12.

Overall System Efficiency

By efficiently transferring coolant between these components, the Water Transfer Tube contributes to the overall efficiency and reliability of the engine’s cooling system. It helps in preventing hotspots within the engine, which can lead to premature wear, reduced performance, and potential engine damage. Moreover, it ensures that the coolant is evenly distributed, allowing for uniform cooling across all engine components 13.

Conclusion

In summary, the Water Transfer Tube is a vital link in the engine’s cooling chain, working in tandem with the manifold and water pump to maintain engine health and performance. Its role in ensuring efficient coolant circulation is crucial for the longevity and reliability of heavy-duty engines, particularly those manufactured by Cummins.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Company Overview. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual (Bulletin Number 4332769). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.