This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

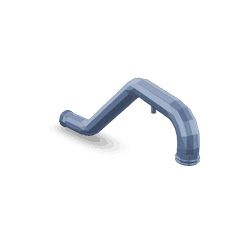

The Cummins 4990335 Water Transfer Tube is a component designed for use in heavy-duty trucks. It facilitates the efficient transfer of coolant between the engine and the radiator, ensuring that the engine operates within optimal temperature ranges for performance and longevity 1.

Basic Concepts and Functionality

Water transfer tubes are integral to the cooling systems of heavy-duty trucks. They operate on the principle of circulating coolant through the engine cooling circuit to dissipate heat. The coolant absorbs heat from the engine and transfers it to the radiator, where it is then released into the atmosphere. This part specifically plays a role in this circuit by providing a conduit for the coolant to travel from the engine to the radiator and back 2.

Purpose of the 4990335 Water Transfer Tube

This Cummins part is designed to facilitate the movement of coolant within the engine cooling system. By ensuring a consistent flow of coolant, it helps maintain the engine’s temperature, which is vital for efficient operation and preventing overheating. This component is engineered to handle the demands of heavy-duty applications, providing reliable performance under various operating conditions.

Key Features

The 4990335 is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the pressures and temperatures encountered in heavy-duty truck engines. The tube’s design includes features that enhance its performance and durability, such as precise engineering to ensure a secure fit and optimal coolant flow.

Benefits

Utilizing this part offers several advantages. It contributes to improved cooling efficiency, which is beneficial for engine performance and longevity. The tube’s durable construction ensures reliability even in demanding operating conditions, reducing the likelihood of failures and the need for frequent replacements.

Installation and Compatibility

Proper installation of this part is crucial for its effective operation. It is designed to be compatible with specific Cummins engine models, ensuring a seamless integration into the cooling system. Installation procedures should follow manufacturer guidelines to ensure the tube is correctly positioned and secured, allowing for optimal coolant flow and system performance.

Troubleshooting and Maintenance

Common issues with this part may include leaks or blockages, which can affect coolant flow and engine cooling efficiency. Regular inspections and maintenance are recommended to identify and address these issues promptly. Maintenance tips include checking for signs of wear or damage, ensuring connections are secure, and replacing the tube according to manufacturer recommendations or when signs of degradation are observed.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industries, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins’ reputation is built on its dedication to producing reliable and high-performance components, ensuring that its customers receive products that meet their demanding needs.

Water Transfer Tube (Part 4990335) in Cummins Engines

The Water Transfer Tube, identified by part number 4990335, is a component in the cooling system of Cummins engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

K38 Engine Group

In the K38 engine series, the Water Transfer Tube plays a pivotal role in the engine’s cooling system. It connects the water pump to the engine block, allowing coolant to flow from the pump to the engine’s core, where it absorbs heat. This tube is engineered to withstand high temperatures and pressures, ensuring durability and reliability under demanding conditions.

The K38 engines, known for their robustness and efficiency, benefit significantly from the precise engineering of the Water Transfer Tube. This part ensures that the coolant circulates effectively, preventing overheating and extending the engine’s lifespan. The design of the tube is such that it minimizes the risk of leaks and blockages, which are common issues in cooling systems.

The integration of the Water Transfer Tube in the K38 engines is a testament to Cummins’ commitment to quality and performance. This part is a key element in the engine’s cooling architecture, contributing to the overall reliability and efficiency of the K38 series.

Role of Part 4990335 Water Transfer Tube in Engine Systems

This part is an essential component in the efficient operation of marine and industrial engine systems, particularly those involving raw water pumps. This tube facilitates the movement of water from the raw water intake to the pump, ensuring a consistent and reliable water flow necessary for engine cooling and other hydraulic functions.

Integration with Raw Water Pump

The Water Transfer Tube connects directly to the raw water pump, providing a dedicated pathway for water to travel from the intake source to the pump’s impeller. This direct connection minimizes the risk of leaks and ensures that the pump receives a steady supply of water, which is vital for its operation. The tube’s design allows it to handle the pressure and flow rates typical in these systems, maintaining performance under various operating conditions.

Ensuring Consistent Water Flow

By linking the raw water intake to the pump, the Water Transfer Tube plays a significant role in maintaining a consistent water flow. This is particularly important in marine environments where the engine is exposed to varying water conditions, such as changes in salinity, temperature, and debris. The tube’s robust construction helps to filter out larger particles, protecting the pump from damage and ensuring that the engine remains cool and operates efficiently.

Support for Engine Cooling Systems

In engine cooling systems, the Water Transfer Tube is a key component that supports the circulation of coolant. It works in conjunction with the raw water pump to draw in water, which is then used to cool the engine’s components. This process is essential for preventing overheating and extending the lifespan of the engine. The tube’s efficient design ensures that water is delivered promptly and in the required volume, supporting the overall cooling efficiency of the system.

Facilitation of Hydraulic Functions

Beyond cooling, the Water Transfer Tube also supports various hydraulic functions within the engine system. It ensures that the necessary water pressure and flow are maintained for components such as power steering systems, hydraulic brakes, and other auxiliary systems that rely on a consistent water supply. This integration highlights the tube’s versatility and importance in maintaining the overall functionality of the engine system.

Conclusion

The Cummins 4990335 Water Transfer Tube is a vital component in the cooling systems of heavy-duty trucks and engines. Its robust design, precise engineering, and reliable performance make it an essential part for maintaining optimal engine temperatures and ensuring efficient operation. Proper installation, regular maintenance, and understanding its role in the engine system are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.