This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding the Cummins 5268369 Water Sensor in Commercial Trucks

Introduction

Water sensors are crucial for the maintenance and performance of commercial truck engines, detecting water contamination in the engine’s cooling system to prevent severe engine damage 1. Cummins, a leader in the automotive industry, offers high-quality engine components, including the 5268369 water sensor, designed for optimal engine performance and longevity 2.

Basic Concepts Related to Water Sensors

A water sensor detects water in a system by changes in electrical resistance and conductivity. When water is present, it alters the sensor’s electrical properties, which are measured and transmitted as a signal to the engine control unit (ECU). This signal allows the ECU to take corrective actions, such as alerting the driver or adjusting engine parameters to prevent damage 3.

Purpose of the Cummins 5268369 Water Sensor

The Cummins 5268369 water sensor is designed to monitor coolant levels and detect water contamination within the engine. Its primary role is to safeguard the engine from potential damage caused by water ingress, ensuring efficient and reliable operation. Accurate water detection is crucial for maintaining engine performance and extending its lifespan 4.

How the Cummins 5268369 Water Sensor Works

The 5268369 water sensor is installed within the engine’s cooling system, continuously monitoring the coolant for water contamination. When water is detected, the sensor sends a signal to the ECU, which processes this information and may trigger alerts or take corrective actions to protect the engine. This proactive approach helps prevent costly repairs and downtime 5.

Troubleshooting the Cummins 5268369 Water Sensor

Common issues with the 5268369 water sensor include engine warning lights and poor engine performance, which may indicate a faulty sensor. To troubleshoot, begin with a visual inspection of the sensor and its connections. Electrical testing can help determine if the sensor is functioning correctly. If a fault is detected, follow the manufacturer’s guidelines for replacement to ensure proper installation and function 6.

Maintenance of the Cummins 5268369 Water Sensor

Preventive maintenance is key to ensuring the longevity and reliability of the 5268369 water sensor. Regular inspection intervals, cleaning to prevent corrosion, and proper coolant maintenance are essential practices. Avoiding coolant contamination and using high-quality coolant can significantly extend the sensor’s lifespan 7.

Cummins: A Leader in Engine Technology

Cummins has long been at the forefront of engine technology, committed to innovation and quality in every component they produce. Their dedication to excellence ensures that using genuine Cummins parts, like the 5268369 water sensor, contributes to optimal engine performance and reliability. Cummins’ expertise in engine technology underscores the importance of selecting the right components for your commercial truck 8.

Expert Insights and Best Practices

Industry experts emphasize the critical role of water sensors in maintaining engine health. Integrating water sensors into routine maintenance schedules and following best practices for their care can prevent unexpected failures and ensure smooth operation. Case studies of water sensor failures highlight the importance of vigilance and proactive maintenance in preserving engine integrity 9.

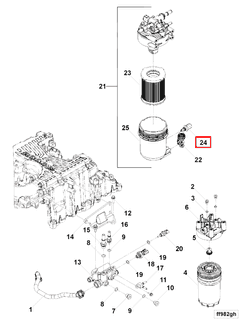

Water Sensor Part 5268369 Compatibility with ISB and ISV Engines

The Water Sensor part 5268369, manufactured by Cummins, is designed to integrate seamlessly with the ISB (Chrysler) and ISV (Nissan) engines. This sensor plays a crucial role in monitoring the coolant temperature, ensuring the engine operates within optimal thermal parameters.

For the ISB engines, the water sensor is strategically placed to provide accurate readings of the coolant temperature. This is essential for the engine control unit (ECU) to make real-time adjustments to the engine’s performance, ensuring efficiency and longevity. The sensor’s placement is designed to avoid interference with other engine components, ensuring smooth operation.

Similarly, in the ISV engines, the water sensor part 5268369 is engineered to fit precisely within the engine’s design. It is positioned to offer reliable temperature data, which is critical for maintaining the engine’s performance and preventing overheating or undercooling conditions. The sensor’s design allows for easy installation and removal, facilitating maintenance and repairs.

Both engines benefit from the precision and reliability of the water sensor part 5268369. Its compatibility with the ISB and ISV engines underscores Cummins’ commitment to providing high-quality components that enhance engine performance and reliability 10.

Role of Part 5268369 Water Sensor in Engine Systems

The 5268369 Water Sensor is an integral component in maintaining the efficiency and reliability of engine systems. It is specifically designed to detect the presence of water in the fuel system, which is essential for preventing potential damage and ensuring optimal engine performance.

Integration with Fuel System Components

-

Fuel Filter: The water sensor is often installed in close proximity to the fuel filter. Its primary function is to monitor the fuel as it passes through the filter. By detecting water early, the sensor helps in preventing water from reaching the engine, which could lead to corrosion and reduced efficiency.

-

Fuel: As fuel travels through the system, the water sensor continuously checks for any water contamination. This is particularly important in diesel engines where water can accumulate in the fuel tank and mix with the diesel, leading to issues such as poor combustion and engine damage.

-

Fuel Filter Location: The strategic placement of the water sensor near the fuel filter location ensures that any water present in the fuel is identified before it can cause harm. This proactive approach allows for timely intervention, such as draining the water from the fuel system, thereby maintaining the integrity of the fuel and the engine.

Operational Benefits

- Early Detection: The sensor’s ability to detect water early in the fuel system allows for prompt action, reducing the risk of engine wear and tear.

- System Integrity: By ensuring that the fuel remains free from water contamination, the sensor contributes to the overall integrity and longevity of the engine system.

- Performance Maintenance: Consistent monitoring and detection help in maintaining engine performance, ensuring that the fuel delivered to the engine is of the highest quality.

Conclusion

The Cummins 5268369 water sensor is a vital component in the engine systems of commercial trucks, playing a crucial role in detecting water contamination and protecting the engine from damage. Proper maintenance and timely troubleshooting are essential for ensuring the sensor’s effectiveness and the engine’s longevity. By utilizing Cummins’ expertise and high-quality components, fleet operators and mechanics can achieve reliable engine performance and reduce the risk of costly repairs 11.

-

Barton, D. C., & Fieldhouse, J. D. (n.d.). Automotive Chassis Engineering.

↩ -

Gifford, C. (n.d.). Cars Encyclopedia.

↩ -

Gilles, T. (2020). Automotive Service Inspection Maintenance Repair. Cengage Learning.

↩ -

Kluczyk, B. (n.d.). How to Rebuild Any Automotive Engine. SA Design.

↩ -

Barton, D. C., & Fieldhouse, J. D. (n.d.). Automotive Chassis Engineering.

↩ -

Gilles, T. (2020). Automotive Service Inspection Maintenance Repair. Cengage Learning.

↩ -

Kluczyk, B. (n.d.). How to Rebuild Any Automotive Engine. SA Design.

↩ -

Barton, D. C., & Fieldhouse, J. D. (n.d.). Automotive Chassis Engineering.

↩ -

Gifford, C. (n.d.). Cars Encyclopedia.

↩ -

Gilles, T. (2020). Automotive Service Inspection Maintenance Repair. Cengage Learning.

↩ -

Kluczyk, B. (n.d.). How to Rebuild Any Automotive Engine. SA Design.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.