This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

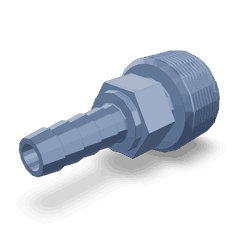

The Cummins 5315842 Water Transfer Connection is a component designed for use in commercial trucks. It facilitates the transfer of coolant within the engine cooling system, ensuring that the engine operates within optimal temperature ranges. This part is integral to maintaining the efficiency and reliability of the truck’s engine, particularly under demanding operational conditions 1.

Basic Concepts of Water Transfer Connection

Water transfer connections in commercial trucks are vital components of the cooling system. They enable the circulation of coolant between different parts of the engine and the cooling system, helping to dissipate heat generated during engine operation. These connections ensure that coolant flows efficiently, which is crucial for preventing engine overheating and maintaining performance 2.

Purpose of the 5315842 Water Transfer Connection

The 5315842 Water Transfer Connection plays a specific role in the operation of a truck by facilitating the transfer of coolant within the engine cooling system. It connects various components, allowing coolant to circulate effectively and maintain the engine’s temperature within safe limits. This ensures that the engine operates efficiently and reliably, even under heavy loads or in high-temperature environments 3.

Key Features

The 5315842 Water Transfer Connection is constructed from durable materials, ensuring it can withstand the pressures and temperatures within the engine cooling system. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, it features corrosion-resistant properties, which enhance its longevity and performance in various operating conditions.

Benefits

Using the 5315842 Water Transfer Connection offers several benefits. It contributes to improved cooling efficiency by ensuring that coolant circulates effectively throughout the engine. Its durable construction and reliable performance help to extend the lifespan of the cooling system components. Additionally, its design enhances the overall reliability of the engine cooling system, reducing the risk of overheating and related issues.

Installation Process

Installing the 5315842 Water Transfer Connection requires careful attention to detail. Begin by ensuring the engine is cool and the cooling system is drained. Use the appropriate tools to remove the old connection and clean the mating surfaces. Apply a compatible sealant to the threads of the new connection before installing it. Tighten the connection to the manufacturer’s specified torque settings to ensure a secure fit. Finally, refill the cooling system and check for leaks to confirm a proper installation.

Common Issues and Troubleshooting

Common issues with the 5315842 Water Transfer Connection may include leaks, corrosion, or blockages. To address these problems, first, inspect the connection for signs of wear or damage. If a leak is detected, ensure the connection is tightened properly or replace it if necessary. Corrosion can be mitigated by using corrosion-resistant materials and regularly inspecting the connection. Blockages may require flushing the cooling system to remove any debris.

Maintenance Tips

Regular maintenance of the 5315842 Water Transfer Connection is important for prolonging its lifespan and ensuring efficient operation. Inspect the connection during routine maintenance checks for signs of wear, corrosion, or leaks. Ensure that the cooling system is free of contaminants by regularly flushing it. Additionally, verify that the connection is tightened to the correct specifications to prevent leaks and ensure optimal performance.

Compatibility and Applications

The 5315842 Water Transfer Connection is compatible with various Cummins engines and is used in different types of commercial trucks. Its design and construction make it suitable for a range of applications, ensuring that it can meet the demands of different operating conditions and environments.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions in the commercial truck industry. With a history of providing reliable and efficient engine technologies, Cummins has established a strong reputation for excellence. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the needs of commercial truck operators.

Water Transfer Connection Part 5315842 Compatibility with Cummins Engines

The Water Transfer Connection part 5315842 is designed to integrate seamlessly with a range of Cummins engines, ensuring efficient water transfer and maintaining optimal engine performance. This part is engineered to fit the following engines:

ISB6.7 G CM2180 B118 and ISL G CM2180

Both the ISB6.7 G CM2180 B118 and ISL G CM2180 engines benefit from the precise fit and functionality of the Water Transfer Connection part 5315842. This part ensures that the water transfer system operates smoothly, contributing to the overall efficiency and longevity of these engines.

L8.9G CMOH2.0 L125B

The L8.9G CMOH2.0 L125B engine also utilizes the Water Transfer Connection part 5315842. This part is critical in maintaining the water transfer system’s integrity, ensuring that the engine operates within its optimal temperature range, thereby enhancing performance and reliability.

Each of these engines, while differing in specifications and applications, relies on the Water Transfer Connection part 5315842 to provide a reliable and efficient water transfer mechanism. This part’s compatibility with these engines underscores its importance in maintaining the engine’s cooling system integrity.

Role of Part 5315842 Water Transfer Connection in Engine Systems

The part 5315842 Water Transfer Connection is integral to the efficient operation of various engine systems. It facilitates the seamless transfer of water between components, ensuring optimal performance and longevity of the engine.

Integration with Crankcase Breather Plumbing

In the arrangement of crankcase breather plumbing, the Water Transfer Connection plays a significant role. It ensures that any moisture or condensation present in the crankcase breather is effectively managed. By connecting to the breather system, it allows for the safe and efficient removal of water vapor, preventing accumulation that could lead to corrosion or reduced efficiency.

Interaction with the Crankcase

The crankcase itself benefits from the Water Transfer Connection by maintaining a dry environment. Any water that enters the crankcase, whether through condensation or other means, is promptly transferred away. This helps in preserving the integrity of the crankcase and its components, reducing the risk of rust and other forms of degradation.

Connection to the Water Inlet

At the water inlet, the Water Transfer Connection ensures a consistent and reliable flow of water into the engine’s cooling system. This is essential for maintaining the engine’s operating temperature within safe limits. The connection point is designed to handle the pressure and flow rates typical of engine cooling systems, ensuring that the water inlet operates efficiently.

Overall System Efficiency

By effectively managing water transfer across these components, the Water Transfer Connection contributes to the overall efficiency and reliability of the engine system. It ensures that water is where it needs to be, when it needs to be there, and that any excess water is safely removed from critical areas like the crankcase and breather system. This not only enhances performance but also extends the lifespan of the engine components.

Conclusion

The Cummins 5315842 Water Transfer Connection is a critical component in the engine cooling system of commercial trucks. Its role in facilitating efficient coolant circulation ensures that the engine operates within optimal temperature ranges, enhancing both performance and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring the longevity and efficiency of the engine cooling system.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.