This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

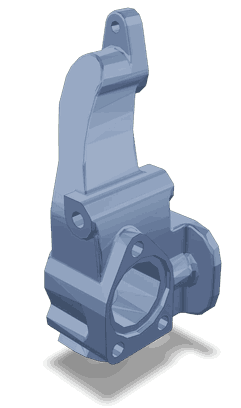

The Water Inlet Connection, part number 5443823, manufactured by Cummins, is a component designed to facilitate the flow of coolant into the engine of heavy-duty trucks. Its role is significant in maintaining the operational efficiency and longevity of the engine. Cummins, a well-established manufacturer in the automotive industry, is known for producing high-quality components that enhance the performance and reliability of heavy-duty vehicles 1.

Basic Concepts of Water Inlet Connection

Water inlet connections in heavy-duty trucks are integral to the engine cooling system. They allow coolant to enter the engine block, where it absorbs heat generated during combustion. Maintaining proper coolant flow is vital for dissipating this heat, preventing engine overheating, and ensuring consistent engine performance. The efficiency of the cooling system directly impacts the engine’s operational lifespan and performance under various conditions 2.

Purpose of the Water Inlet Connection

This Cummins part is specifically designed to play a role in the engine cooling system by ensuring a steady and efficient flow of coolant into the engine. This component contributes to maintaining optimal engine temperature, which is crucial for engine performance and longevity. By facilitating effective coolant circulation, it helps in dissipating heat away from the engine, thus supporting overall engine efficiency and reliability 3.

Key Features

The Water Inlet Connection is characterized by several design elements and materials that enhance its performance and durability. It is constructed from high-quality materials to withstand the demanding conditions of heavy-duty truck engines. Its design ensures a secure fit and efficient coolant flow, contributing to the overall effectiveness of the engine cooling system.

Benefits

Using the Water Inlet Connection offers several advantages, including improved coolant flow and enhanced engine cooling efficiency. These benefits contribute to increased reliability under demanding conditions, supporting the engine’s performance and longevity. The component’s design and materials also contribute to its durability, making it a reliable choice for heavy-duty truck applications.

Installation Process

Installing the Water Inlet Connection requires careful preparation and the use of appropriate tools. The process involves securing the connection to ensure a tight and effective fit, which is crucial for maintaining proper coolant flow and engine cooling efficiency. Following best practices during installation helps in achieving optimal performance and longevity of the component.

Maintenance Tips

To ensure the optimal performance and longevity of the Water Inlet Connection, regular inspections and maintenance are recommended. This includes checking for any signs of wear or damage, cleaning the component as necessary, and following replacement guidelines to prevent issues such as leaks or blockages that could affect engine cooling efficiency.

Troubleshooting Common Issues

Common problems associated with water inlet connections, such as leaks or blockages, can impact engine cooling efficiency. Identifying these issues early and applying appropriate troubleshooting steps can help in maintaining the effectiveness of the engine cooling system. Solutions may include tightening connections, cleaning the component, or replacing it if necessary.

Compatibility with Cummins Engines

The Water Inlet Connection part 5443823 is compatible with various Cummins engines, including the B6.7 series and the ISBE series. Its design ensures that it can effectively manage coolant flow in these engines, contributing to their overall performance and longevity.

B6.7 Series Engines

The B6.7 series includes the B6.7 CM2350 B135B and B6.7 CM2670 B153B engines. The Water Inlet Connection is designed to fit seamlessly with these engines, providing a reliable seal and ensuring efficient coolant flow.

ISBE Series Engines

The ISBE series, represented by the ISBE CM2150 and ISBE4 CM850 engines, also utilizes the Water Inlet Connection. This part is engineered to integrate perfectly with the ISBE engines, ensuring that the coolant is directed correctly into the engine block.

Role of Part 5443823 in Engine Systems

The Water Inlet Connection, identified by part number 5443823, is integral to the efficient operation of various engine systems. Its primary function is to facilitate the entry of coolant into the engine block, ensuring that the coolant can circulate effectively throughout the system.

Integration with Engine Components

- Engine Block: The water inlet connection is directly attached to the engine block, allowing coolant to enter the block’s coolant passages.

- Thermostat Housing: Often, the water inlet connection is part of the thermostat housing assembly.

- Coolant Hoses: The inlet connection interfaces with the coolant hoses, which transport coolant from the radiator to the engine.

- Water Pump: The water inlet connection works in conjunction with the water pump to ensure a consistent flow of coolant.

- Radiator: The connection plays a role in the overall coolant circulation loop, which includes the radiator.

- Coolant Reservoir: In systems with an overflow tank, the water inlet connection may also interact with the coolant reservoir.

Conclusion

The Water Inlet Connection, part number 5443823, is a critical component in the cooling system of various Cummins engines. Its design ensures the proper flow of coolant into the engine, which is essential for maintaining optimal operating temperatures and preventing overheating. By understanding the role of this part within these engine systems, engineers and mechanics can better appreciate its importance in maintaining engine health and performance.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.