Introduction

This article provides an overview of the Water Inlet Connection 3920352, a component manufactured by Cummins. It explains the function, purpose, key features, and benefits of this part within the context of commercial truck operations.

Basic Concepts of Water Inlet Connection

A water inlet connection is a component used in the cooling system of an engine. It facilitates the entry of coolant into the engine block, ensuring efficient heat dissipation. The connection is typically made of durable materials to withstand high temperatures and pressures 1.

Function and Purpose of Water Inlet Connection 3920352

The Water Inlet Connection 3920352 plays a role in the engine cooling system by allowing coolant to enter the engine block. This part ensures that the coolant circulates properly, maintaining optimal engine temperature and preventing overheating 2.

Key Features

- Constructed from high-quality materials to ensure durability and resistance to corrosion.

- Designed to fit specific engine models, ensuring proper alignment and function.

- Features precise threading and sealing surfaces to prevent coolant leaks.

- Engineered to withstand high temperatures and pressures typical in heavy-duty truck engines 3.

Benefits

- Enhances the efficiency of the engine cooling system by ensuring proper coolant flow.

- Contributes to the longevity of the engine by maintaining consistent operating temperatures.

- Reduces the risk of engine damage due to overheating.

- Designed for easy installation and replacement, minimizing downtime for maintenance.

Troubleshooting and Maintenance

Regular inspection of the Water Inlet Connection 3920352 is recommended to identify any signs of wear or damage. Common issues include leaks, corrosion, and blockages. Maintenance tips include:

- Checking for coolant leaks around the connection.

- Ensuring the sealing surfaces are clean and free from debris.

- Replacing the connection if there are signs of significant wear or damage.

- Following the manufacturer’s guidelines for maintenance intervals and procedures 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Known for its commitment to quality and innovation, Cummins serves commercial, industrial, and automotive markets worldwide.

Compatibility with Cummins Engines

-

6B5.9 and B5.9 G Engines

The Water Inlet Connection part 3920352 is designed to fit seamlessly with the 6B5.9 and B5.9 G engines. These engines are known for their robust performance and reliability, and the water inlet connection plays a vital role in their cooling system by ensuring that water flows correctly into the engine block.

-

B5.9 GAS PLUS CM556 and ISB CM550 Engines

Similarly, the part 3920352 is also compatible with the B5.9 GAS PLUS CM556 and ISB CM550 engines. These engines benefit from the precise fit and function of the water inlet connection, which is essential for maintaining the engine’s cooling efficiency. The CM556 and CM550 models are part of Cummins’ advanced engine lineup, known for their power and efficiency, and the water inlet connection is a key component in their cooling systems.

Role of Part 3920352 Water Inlet Connection in Engine Systems

The part 3920352 Water Inlet Connection is an essential component in the cooling system of various engine setups. Its primary function is to facilitate the entry of coolant into the engine block, ensuring that the engine operates within optimal temperature ranges.

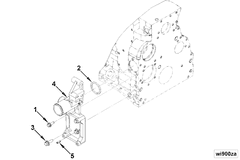

Integration with Engine Components

-

Engine Block: The water inlet connection is directly attached to the engine block. It allows coolant to flow into the water jackets surrounding the cylinders. This helps in dissipating heat generated during combustion.

-

Thermostat Housing: Often, the water inlet connection is part of the thermostat housing assembly. This setup ensures that the coolant flow is regulated based on the engine temperature, maintaining efficiency and preventing overheating.

-

Coolant Hoses: The connection point for the upper and lower radiator hoses is typically integrated into the water inlet. This allows for a seamless flow of coolant between the engine and the radiator, enhancing the cooling process.

-

Water Pump: The water inlet connection works in conjunction with the water pump to circulate coolant throughout the engine. The pump draws coolant from the radiator and pushes it through the engine block via the inlet connection.

-

Radiator: The connection plays a role in the coolant’s journey to the radiator, where heat is dissipated. The efficient design of the inlet ensures that coolant flow is consistent, aiding in the radiator’s effectiveness.

-

Heater Core: In systems where the engine’s coolant also services the vehicle’s heater, the water inlet connection ensures that warm coolant is available for the heater core, providing cabin heating.

-

Pressure Cap: The water inlet connection often interfaces with the pressure cap of the cooling system. This cap helps maintain system pressure, which raises the boiling point of the coolant and improves overall cooling efficiency.

Conclusion

By understanding the role of the water inlet connection within these components, engineers and mechanics can better appreciate its significance in maintaining engine health and performance.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

David C Barton and John D Fieldhouse, Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, Elsevier, 2009.

↩ -

Cummins Inc., Marine QSB6.7 CM2250, Bulletin Number 4310612, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.