This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

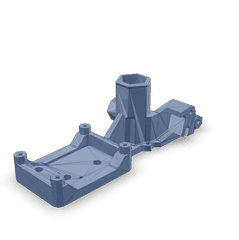

The Water Inlet Connection 3942509 is a component designed by Cummins for use in commercial trucks. This part is integral to the operation of the truck’s cooling system, facilitating the efficient flow of coolant to maintain optimal engine temperature. Its role is significant in ensuring the engine operates within safe thermal limits, thereby contributing to the overall performance and longevity of the vehicle.

Basic Concepts of Water Inlet Connection

Water inlet connections in truck cooling systems serve as conduits for coolant to enter the engine block. These connections are designed to ensure a steady and uninterrupted flow of coolant, which is vital for dissipating heat generated during engine operation. The operation of these connections involves precise engineering to handle the pressures and temperatures associated with engine cooling systems 1.

Purpose of Water Inlet Connection 3942509

The Water Inlet Connection 3942509 plays a role in the truck’s cooling system by allowing coolant to flow into the engine block. This part ensures that coolant is distributed evenly throughout the engine, which helps in maintaining consistent temperatures across all engine components. By facilitating efficient coolant flow, it contributes to the engine’s thermal management, which is crucial for preventing overheating and ensuring smooth operation 2.

Key Features

The Water Inlet Connection 3942509 is characterized by several key features that enhance its performance. Its design is engineered to withstand the high pressures and temperatures typical of commercial truck engines. The materials used in its construction are selected for their durability and resistance to corrosion, ensuring long-term reliability. Additionally, the connection may feature unique attributes such as precise threading or sealing mechanisms to ensure a secure fit and prevent leaks 3.

Benefits

The advantages provided by the Water Inlet Connection 3942509 include improved coolant flow, which enhances the engine’s cooling efficiency. This part contributes to enhanced engine protection by ensuring that all components are adequately cooled, reducing the risk of thermal damage. Furthermore, its reliable design and construction increase the overall reliability of the truck’s cooling system, leading to fewer maintenance issues and longer service intervals 4.

Installation Process

Installing the Water Inlet Connection 3942509 requires careful attention to detail to ensure proper function and longevity. The process involves several steps: first, ensuring the engine is cool and the cooling system is drained; second, removing the old connection if applicable; third, cleaning the installation area to remove any debris or old gasket material; fourth, applying a compatible sealant to the threads of the new connection; and finally, tightening the connection to the manufacturer’s specified torque settings. It is important to follow these steps meticulously to avoid leaks and ensure a secure fit.

Common Issues and Troubleshooting

Typical problems associated with water inlet connections can include leaks, corrosion, and blockages. Troubleshooting these issues involves inspecting the connection for signs of wear or damage, checking for proper torque on the connection, and ensuring that the sealing surfaces are clean and free of debris. Solutions may range from simple cleaning and re-torquing to replacement of the connection if damage is detected.

Maintenance Tips

To ensure optimal performance and longevity of the Water Inlet Connection 3942509, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the connection and its surrounding areas can prevent buildup that may impede coolant flow. Additionally, following the manufacturer’s guidelines for coolant type and change intervals can contribute to the overall health of the cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of various industries, emphasizing performance, efficiency, and sustainability.

Cummins Engine Compatibility with Water Inlet Connection Part 3942509

The Water Inlet Connection part 3942509, manufactured by Cummins, is a critical component in the cooling system of certain Cummins engines. This part ensures the proper flow of coolant into the engine, maintaining optimal operating temperatures and preventing overheating. Below is a detailed overview of the engines that are compatible with this specific part.

ISB CM550 Engine Series

The ISB CM550 engine series is known for its robust performance and reliability, making it a popular choice in various industrial and commercial applications. The Water Inlet Connection part 3942509 is designed to fit seamlessly into the cooling system of these engines, ensuring efficient coolant flow and maintaining engine integrity.

Cummins QSK Series

The Cummins QSK series, which includes models such as the QSK19, QSK45, and QSK60, are high-power diesel engines used in a variety of applications, from marine to power generation. The Water Inlet Connection part 3942509 is engineered to integrate with the cooling systems of these engines, providing a reliable connection point for the coolant inlet.

Cummins L10 Engine

The Cummins L10 engine is a high-performance, medium-speed diesel engine used extensively in marine and stationary power applications. The Water Inlet Connection part 3942509 is specifically designed to fit the L10 engine’s cooling system, ensuring that the coolant flows smoothly and efficiently, which is crucial for maintaining the engine’s operational efficiency and longevity.

Cummins K19 Engine

The Cummins K19 engine is a high-speed diesel engine known for its reliability and efficiency. It is commonly used in marine and industrial applications. The Water Inlet Connection part 3942509 is compatible with the K19 engine’s cooling system, providing a secure and efficient connection for the coolant inlet, which is essential for the engine’s cooling process.

Cummins M11 Engine

The Cummins M11 engine is a medium-speed diesel engine that is widely used in various applications, including military vehicles and industrial power generation. The Water Inlet Connection part 3942509 is designed to fit the M11 engine’s cooling system, ensuring that the coolant flows properly, which is vital for the engine’s performance and durability.

By ensuring that the Water Inlet Connection part 3942509 is correctly installed in these engines, users can maintain the efficiency and reliability of their Cummins engines, preventing potential issues related to coolant flow and engine overheating.

Role of Part 3942509 Water Inlet Connection in Engine Systems

The part 3942509 Water Inlet Connection is an essential component in the cooling system of various engine setups. Its primary function is to facilitate the entry of coolant into the engine block, ensuring that the engine maintains optimal operating temperatures.

Integration with Engine Components

-

Engine Block: The Water Inlet Connection is directly attached to the engine block. It serves as the entry point for coolant, which is vital for dissipating heat generated during combustion.

-

Thermostat Housing: Often, the Water Inlet Connection is part of the thermostat housing assembly. This allows for regulated coolant flow based on engine temperature, enhancing efficiency and performance.

-

Coolant Hoses: The connection point for coolant hoses is typically integrated into the Water Inlet Connection. These hoses transport coolant between the engine and the radiator, ensuring a continuous cooling cycle.

-

Radiator: The Water Inlet Connection plays a role in the pathway that coolant takes from the engine to the radiator. Efficient coolant flow through this connection is necessary for heat exchange in the radiator.

-

Water Pump: The connection is also part of the route that coolant takes from the water pump to the engine block. The water pump circulates coolant throughout the system, and the Water Inlet Connection ensures this circulation is uninterrupted.

-

Heater Core: In systems where the engine’s coolant also services the vehicle’s heating system, the Water Inlet Connection is part of the pathway to the heater core, allowing for efficient heat distribution inside the vehicle.

-

Pressure Cap: The Water Inlet Connection may also be involved in maintaining system pressure, often working in conjunction with a pressure cap to prevent coolant loss and ensure system integrity.

In summary, the Water Inlet Connection (part 3942509) is a pivotal component in the engine’s cooling system, ensuring that coolant is efficiently distributed to maintain engine temperature within safe operating limits.

Conclusion

The Water Inlet Connection 3942509 by Cummins is a critical component in the cooling systems of commercial trucks and various Cummins engines. Its design and features ensure efficient coolant flow, contributing to engine performance, longevity, and reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part and ensure the optimal operation of the engine cooling system.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.