This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3005882 Water Outlet Connection is a critical component in heavy-duty truck engines, designed to facilitate the efficient transfer of coolant from the engine to the radiator. This part ensures the engine operates within safe temperature ranges, playing a vital role in the engine cooling system 4.

Basic Concepts of Water Outlet Connections

A water outlet connection directs coolant flow from the engine to the radiator, ensuring the coolant, after absorbing heat, is efficiently transported to the radiator for cooling. This continuous circulation is essential for maintaining the engine’s temperature within a specified range, preventing overheating and ensuring efficient engine operation 1.

Purpose of the Cummins 3005882 Water Outlet Connection

The Cummins 3005882 is engineered to direct coolant flow from the engine to the radiator in heavy-duty trucks. It ensures a consistent and efficient flow of coolant, maintaining the engine’s temperature, which is crucial for performance and longevity. This component is built to withstand the high pressures and temperatures typical of heavy-duty engine environments 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, contributing to its durability and performance. It is designed to fit securely, ensuring a leak-free seal that maintains the integrity of the cooling system. Its construction allows it to withstand the rigors of heavy-duty use, including exposure to high temperatures and pressures 3.

Benefits

Utilizing the Cummins 3005882 offers several advantages. It contributes to improved engine efficiency by ensuring optimal coolant flow, which helps in maintaining the engine’s temperature. Its durable construction ensures reliable performance under various operating conditions, reducing the likelihood of failures. Additionally, its design enhances the overall efficiency of the cooling system, potentially leading to extended engine life 4.

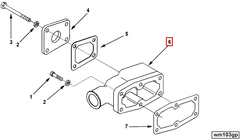

Installation Process

Installing the Water Outlet Connection requires careful attention to ensure a secure and effective fit. The process involves preparing the engine area, ensuring the surface is clean and free of debris. The connection should be aligned correctly with the engine and radiator components before being secured in place. It is important to follow manufacturer guidelines for torque specifications to avoid over-tightening, which could damage the component or lead to leaks 3.

Common Issues and Troubleshooting

Common issues with the Water Outlet Connection may include leaks or blockages. Leaks can often be traced to improper installation or wear and tear over time. Blockages may occur due to debris in the coolant system. Troubleshooting involves inspecting the connection for signs of wear, ensuring it is properly installed, and checking the coolant system for debris. Regular maintenance can help prevent these issues 1.

Maintenance Tips

To prolong the lifespan of the Water Outlet Connection, regular inspections are recommended. This includes checking for signs of wear or damage and ensuring there are no leaks. Cleaning the connection and the surrounding area can prevent debris from entering the cooling system. Following recommended maintenance intervals for coolant changes and system inspections can also contribute to the component’s longevity and performance 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance automotive components. The company’s commitment to quality and customer satisfaction is evident in its wide range of products, including the Cummins 3005882 Water Outlet Connection 3.

Integration with Engine Components

The Water Outlet Connection, identified as part 3005882, is integral to the efficient operation of various engine systems by facilitating the controlled flow of coolant. This component interfaces with several key elements within the engine’s cooling system, ensuring optimal performance and longevity of the engine.

-

Connection Water Header: The Water Outlet Connection is designed to link directly with the Connection Water Header, allowing for a seamless transition of coolant from the engine block to the header. This connection is vital for maintaining consistent coolant flow, which is essential for regulating engine temperature.

-

Cover Water Header and Water Header Cover: Once coolant exits the engine block via the Water Outlet Connection, it often passes through the Cover Water Header or Water Header Cover. These components help in directing the coolant towards the radiator or other cooling elements, ensuring that the engine remains within its optimal operating temperature range.

-

Water Manifold: In systems where multiple cylinders or components require cooling, the Water Outlet Connection plays a role in distributing coolant to the Water Manifold. This manifold then channels the coolant to various parts of the engine, ensuring uniform cooling across all critical areas.

-

Wtr Hdr Cover: Similar to the Water Header Cover, the Wtr Hdr Cover is another point of interface for the Water Outlet Connection. This cover helps in sealing the system, preventing leaks and ensuring that the coolant remains within the designated pathways.

-

Plumbing: The Water Outlet Connection is a key component in the overall plumbing of the engine’s cooling system. It ensures that the coolant pathways are correctly aligned and that there are no obstructions or leaks in the system.

-

Oil Cooler Water: In engines where an oil cooler is employed, the Water Outlet Connection may also interface with the Oil Cooler Water system. This integration allows for the efficient transfer of heat from the engine oil to the coolant, enhancing the overall cooling efficiency of the engine.

By understanding the role of the Water Outlet Connection within these systems, engineers and mechanics can better appreciate its importance in maintaining engine health and performance. Proper installation and maintenance of this component are essential for the reliable operation of the engine’s cooling system 4.

Conclusion

The Cummins 3005882 Water Outlet Connection is a vital component in the engine cooling system of heavy-duty trucks. Its role in facilitating efficient coolant flow ensures the engine operates within safe temperature ranges, contributing to engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Steve Rendle, Martynn Randall, Haynes Diesel Engine Systems and Data Book, Haynes Publishing, 2000.

↩ ↩ -

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice, CRC Press, 2011.

↩ ↩ -

Cummins Inc., Service Manual (6396899), B6.7 CM2350 B198C.

↩ ↩ ↩ -

Kirk T Van Gelder, Fundamentals of Automotive Technology Principles and Practice, Jones Bartlett Learning, 2018.

↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.