This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3019999 Compression Spring is a specialized component designed for use in commercial trucks. Its purpose is to provide necessary tension and support within various truck systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its function and significance is vital for maintaining optimal truck performance.

Basic Concepts of Compression Springs

Compression springs are mechanical devices that resist compression forces. They are designed to store and release energy when compressed and released, respectively. These springs find applications in a wide range of mechanical systems, including automotive, industrial machinery, and consumer products. Their primary function is to absorb shock, maintain pressure, and ensure smooth operation of mechanical components 1.

Role of the 3019999 Compression Spring in Truck Operation

The Cummins 3019999 Compression Spring plays a specific role in the operation of commercial trucks by providing the necessary tension and support in various systems. It is typically placed within the truck’s suspension system, where it helps to absorb shocks and vibrations from the road, ensuring a smoother ride and reducing wear on other components. Additionally, it may be used in the engine system to maintain pressure and ensure the proper functioning of valves and other moving parts 2.

Key Features of the 3019999 Compression Spring

The Cummins 3019999 Compression Spring is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, such as stainless steel or spring steel, which offer excellent resistance to corrosion and fatigue. The design specifications of the spring, including its coil diameter, wire diameter, and number of coils, are meticulously engineered to meet the specific requirements of commercial truck applications. Additionally, the spring may feature unique attributes such as a specific rate of compression or a particular load capacity to ensure optimal performance under varying conditions 3.

Benefits of Using the 3019999 Compression Spring

The use of the Cummins 3019999 Compression Spring offers several benefits in truck operations. Its high-quality material composition and precise design specifications contribute to improved performance, durability, and reliability. The spring’s ability to absorb shocks and maintain pressure ensures a smoother ride and reduces wear on other components, leading to lower maintenance costs and increased vehicle lifespan. Furthermore, its resistance to corrosion and fatigue makes it suitable for use in demanding commercial environments.

Installation and Integration

Proper installation and integration of the Cummins 3019999 Compression Spring are crucial for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the spring is correctly aligned and seated within the truck’s system, using appropriate tools and techniques to avoid damage, and verifying that all connections are secure. Following these practices helps to prevent issues such as misalignment, excessive wear, or failure of the spring, ensuring it functions as intended.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 3019999 Compression Spring include compression fatigue, corrosion, and misalignment. Troubleshooting steps to address these problems effectively include regular inspection for signs of wear or damage, cleaning and lubricating the spring to prevent corrosion, and ensuring proper alignment and seating within the truck’s system. In cases where the spring shows significant signs of wear or failure, replacement with a new spring is recommended to maintain optimal performance.

Maintenance Tips

Practical maintenance tips for the Cummins 3019999 Compression Spring include regular inspection practices and recommended service intervals. Inspecting the spring for signs of wear, corrosion, or misalignment during routine maintenance checks helps to identify potential issues early and prevent more significant problems. Additionally, following recommended service intervals for replacement or reconditioning ensures the spring continues to perform efficiently and reliably over time.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and quality in the automotive industry. The company’s extensive product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ dedication to research and development ensures that its products, including the 3019999 Compression Spring, continue to evolve and provide superior performance and reliability.

Compression Spring Part 3019999 in Cummins Engines

The Compression Spring part 3019999, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to provide the necessary compression force in various engine applications, ensuring optimal performance and longevity.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Compression Spring part 3019999 plays a vital role in maintaining the integrity of the engine’s internal components. It is typically used in conjunction with valve mechanisms, ensuring that the valves operate smoothly and efficiently. This spring helps in returning the valves to their closed position after they have been actuated, which is crucial for the engine’s overall functionality.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Compression Spring part 3019999 is integral to the engine’s operation. This part is often utilized in the fuel injection system, where it ensures that the injectors return to their closed position after delivering fuel. The spring’s ability to withstand repeated compression and decompression cycles makes it an essential component for maintaining the precision and reliability of the fuel injection process.

The use of the Compression Spring part 3019999 across these engine models underscores its importance in ensuring that the engines operate efficiently and reliably. Cummins’ design and manufacturing of this part reflect their commitment to quality and performance in their engine components.

Role of Part 3019999 Compression Spring in Engine Systems

The part 3019999 Compression Spring is instrumental in various engine systems, enhancing their functionality and performance. Here’s how it integrates with several key components:

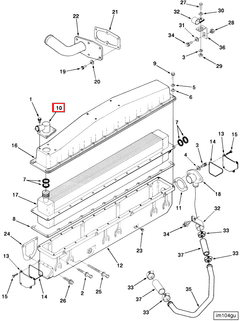

After Cooler and Aftercooler Conversion Kit

In the after cooler system, the Compression Spring assists in maintaining consistent pressure within the cooling circuit. It ensures that the compressed air is evenly distributed, which is vital for efficient cooling of the air charge before it enters the engine. In the aftercooler conversion kit, the spring helps in the smooth transition and adaptation of the new components, ensuring that the system operates seamlessly.

Aftercooler Front Plumbing

Within the aftercooler front plumbing, the Compression Spring plays a role in regulating the flow of coolant. It helps in maintaining the pressure required for optimal heat exchange, thereby enhancing the efficiency of the aftercooler.

Air Assembly Intercooler and Air Intake Manifold

In the air assembly intercooler, the Compression Spring is used to manage the pressure within the intercooler housing. This ensures that the air is cooled effectively before it is sent to the air intake manifold. In the air intake manifold, the spring helps in maintaining a consistent airflow, which is essential for the proper combustion process within the engine cylinders.

Air Intake Manifold Assembly and Air Intercooler

For the air intake manifold assembly, the Compression Spring ensures that the manifold can withstand the pressure variations without compromising the structural integrity. In the air intercooler, it aids in the efficient transfer of heat from the compressed air to the cooling medium, thus improving the overall performance of the engine.

Air Mounting Intercooler

The Compression Spring in the air mounting intercooler setup helps in securing the intercooler in place while allowing for some degree of movement. This is important for absorbing vibrations and ensuring that the intercooler remains functional under varying engine loads.

Intake Manifold and Intercooler Air

In the intake manifold, the Compression Spring ensures that the manifold can adapt to changes in pressure without failing. For the intercooler air system, it helps in maintaining the pressure differential required for effective heat exchange, thus ensuring that the air entering the engine is at the optimal temperature.

Intercooler Connection and Manifold

Finally, in the intercooler connection and manifold, the Compression Spring ensures that the connections remain tight and secure. This is important for preventing leaks and ensuring that the system operates at peak efficiency. The spring also helps in managing the pressure within the manifold, contributing to a stable and reliable engine performance.

Conclusion

The Cummins 3019999 Compression Spring is a vital component in the operation of commercial trucks and various engine systems. Its role in providing necessary tension, support, and maintaining pressure ensures optimal performance, durability, and reliability. Proper installation, regular maintenance, and timely replacement are essential practices to ensure the continued efficiency and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.