This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

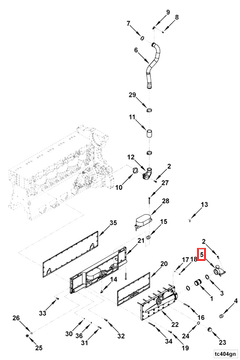

The Water Outlet Connector 3200211 by Cummins is a component designed to facilitate the efficient operation of the engine cooling system in commercial trucks. Its purpose is to ensure that coolant is effectively distributed throughout the engine, helping to maintain optimal operating temperatures and enhance engine performance and longevity.

Basic Concepts of Water Outlet Connectors

A Water Outlet Connector is a part of the engine cooling system that directs coolant flow from the engine block to other parts of the cooling system, such as the radiator. It plays a role in maintaining optimal engine temperature by ensuring that coolant circulates efficiently, absorbing heat from the engine and dissipating it through the radiator 1.

Purpose of the 3200211 Water Outlet Connector

The 3200211 Water Outlet Connector is specifically designed to fit into the cooling system of commercial trucks, where it connects the engine block to the upper radiator hose. This connector ensures a secure and leak-free connection, allowing coolant to flow from the engine to the radiator, where it is cooled before returning to the engine. Its position in the cooling system is critical for the effective operation of the engine, as it ensures that coolant is evenly distributed and that the engine remains at an optimal temperature 2.

Key Features

The 3200211 Water Outlet Connector is constructed from durable materials that are resistant to corrosion and high temperatures, ensuring long-lasting performance. It features a precise sealing mechanism that prevents coolant leaks, maintaining the integrity of the cooling system. Additionally, its design allows for easy installation and removal, facilitating maintenance and repair processes.

Benefits

The 3200211 Water Outlet Connector offers several advantages, including improved coolant flow due to its efficient design, enhanced sealing that prevents leaks and maintains system pressure, and a contribution to engine longevity and efficiency by ensuring optimal coolant circulation. These benefits help to protect the engine from overheating and extend its operational life 3.

Installation Process

Installing the 3200211 Water Outlet Connector involves several steps to ensure a secure and effective fit. Preparatory steps include cleaning the mating surfaces on the engine block and ensuring that all old gasket material is removed. The connector should be aligned with the engine block and secured according to the manufacturer’s specifications, using the appropriate tools to avoid damage. It is important to follow best practices, such as torquing bolts to the specified settings, to ensure a leak-free connection.

Troubleshooting Common Issues

Common problems associated with Water Outlet Connectors include leaks and blockages. Leaks can often be traced to improper installation, damaged gaskets, or corrosion. Blockages may result from debris in the cooling system or a malfunctioning thermostat. Troubleshooting steps include inspecting the connector and its connections for signs of damage or wear, checking for proper installation, and ensuring that the cooling system is free of debris.

Maintenance Tips

Regular maintenance of the 3200211 Water Outlet Connector is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the connector and its connections to remove any buildup, and replacing gaskets or seals as needed. Adhering to recommended inspection intervals and following proper cleaning procedures will help to maintain the efficiency of the cooling system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of engine components, including the 3200211 Water Outlet Connector, which is designed to meet the demanding requirements of commercial truck engines.

Water Outlet Connector Part 3200211 Compatibility with Cummins Engines

The Water Outlet Connector part 3200211, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for the proper functioning of the engine’s cooling system, ensuring that coolant flows efficiently and maintains optimal engine temperature.

K19 Series Engines

The K19 series engines, including the K19, KTA19GC, KTA19GC CM558, QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, all utilize the Water Outlet Connector part 3200211. This part is engineered to fit seamlessly into the cooling system architecture of these engines, providing a reliable connection point for the water outlet.

K19 and KTA19GC Engines

For the K19 and KTA19GC engines, the Water Outlet Connector part 3200211 is a critical component that ensures the coolant exits the engine block and enters the radiator or cooling system. This part is designed to withstand the high temperatures and pressures typical of these engines, ensuring durability and longevity.

KTA19GC CM558 Engine

The KTA19GC CM558 engine also relies on the Water Outlet Connector part 3200211. This specific model is often used in heavy-duty applications, and the connector’s robust design helps maintain the integrity of the cooling system under demanding conditions.

QSK19 CM2350 Series Engines

The QSK19 CM2350 K105, QSK19 CM2350 K114, and QSK19 CM2350 K144G engines are part of the QSK19 series, which are known for their high performance and reliability. The Water Outlet Connector part 3200211 is essential for these engines, providing a secure and efficient connection for the coolant flow.

QSK19 CM500 and QSK19 CM850 MCRS Engines

The QSK19 CM500 and QSK19 CM850 MCRS engines are designed for demanding applications, and the Water Outlet Connector part 3200211 is a key component in their cooling systems. This part ensures that the coolant is directed properly, maintaining the engine’s optimal operating temperature.

QSK19G Engine

The QSK19G engine, part of the QSK19 series, also utilizes the Water Outlet Connector part 3200211. This engine is known for its efficiency and power, and the connector plays a vital role in its cooling system, ensuring that the engine operates smoothly and reliably.

Role of Part 3200211 Water Outlet Connector in Engine Systems

The part 3200211 Water Outlet Connector is integral to the efficient operation of various engine systems by facilitating the connection and regulation of coolant flow. This component ensures that the coolant is distributed effectively across multiple cooling systems, enhancing the overall performance and longevity of the engine.

Integration with Cooling Systems

-

Cooler and Engine Oil Cooler: The Water Outlet Connector plays a significant role in the cooler and engine oil cooler systems. It ensures that the coolant is properly directed to these components, allowing for the effective dissipation of heat generated by the engine oil. This helps maintain optimal oil viscosity and prevents overheating, which can lead to engine damage.

-

Torque Converter Oil Cooler: In systems equipped with a torque converter, the Water Outlet Connector is responsible for routing coolant to the torque converter oil cooler. This is essential for maintaining the temperature of the transmission fluid, ensuring smooth operation and preventing thermal degradation of the fluid.

-

Keel Cooling System: For engines with a keel cooling system, the Water Outlet Connector is vital in directing coolant to the lower parts of the engine, where keel cooling is employed. This helps in evenly distributing the cooling effect, reducing hotspots, and enhancing the engine’s thermal efficiency.

Plumbing and Flow Regulation

-

Plumbing Systems: The Water Outlet Connector is a key component in the plumbing systems of engine cooling circuits. It ensures that the coolant flows seamlessly from the engine block to the various coolers and back, maintaining a consistent cooling loop. This is essential for the reliable operation of the engine under varying loads and conditions.

-

Oil Cooler Water Plumbing: In systems where oil coolers are water-cooled, the Water Outlet Connector facilitates the connection between the engine’s water cooling system and the oil cooler. This integration ensures that the oil remains at an optimal temperature, reducing the risk of sludge formation and enhancing lubrication efficiency.

-

Torque Converter Cooler Plumbing: Similarly, for torque converter coolers, the Water Outlet Connector ensures that the coolant is effectively routed to and from the cooler. This maintains the temperature of the transmission fluid within safe limits, contributing to the durability and performance of the transmission system.

Conclusion

In summary, the part 3200211 Water Outlet Connector is a fundamental component in the coolant distribution network of engine systems. Its proper function ensures that all critical components receive adequate cooling, thereby supporting the engine’s efficiency, reliability, and longevity.

-

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ -

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.