This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

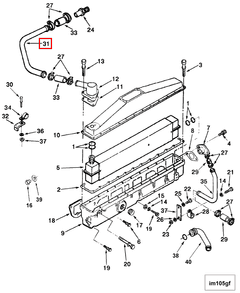

The Cummins 3036996 Water Transfer Tube is a component designed to facilitate the movement of coolant within the cooling system of heavy-duty trucks. Its purpose is to ensure efficient heat dissipation from the engine, contributing to the overall performance and longevity of the vehicle. The significance of this part lies in its ability to maintain optimal engine temperature under various operating conditions 1.

Function and Operation

The Water Transfer Tube operates by channeling coolant between different components of the truck’s cooling system. It plays a role in transferring coolant from the engine to the radiator and other cooling components, ensuring that heat is effectively managed. This process involves the circulation of coolant through the engine block, where it absorbs heat, and then through the radiator, where the heat is dissipated into the atmosphere 2.

Key Features

The design and construction of the 3036996 Water Transfer Tube include several features that enhance its performance. It is typically made from durable materials that can withstand high temperatures and pressures. The tube may feature specific connection types to ensure a secure fit within the cooling system. Additionally, it might include unique attributes such as reinforced sections to prevent leaks and ensure longevity 3.

Role in Truck Operation

The Water Transfer Tube plays a role in maintaining optimal engine temperature by ensuring consistent coolant flow throughout the system. This helps in preventing overheating, which can lead to engine damage. By facilitating efficient heat exchange, the tube contributes to the truck’s overall operational efficiency and reliability 4.

Benefits

The Cummins 3036996 Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the cooling system’s efficiency. The tube’s durable construction ensures reliability even in demanding conditions. Additionally, its design may contribute to reduced maintenance needs and longer service life 5.

Installation Considerations

When installing the Water Transfer Tube, it is important to follow guidelines and best practices to ensure proper integration within the cooling system. This includes ensuring correct alignment, using appropriate sealing methods, and verifying that all connections are secure. Proper installation is key to maintaining the efficiency and reliability of the cooling system 6.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube involves regular inspection for signs of wear, leaks, or damage. It is advisable to check the connections and seals periodically to ensure they remain intact. Troubleshooting common issues may involve identifying leaks, assessing the condition of the tube, and addressing any abnormalities in coolant flow 7.

Manufacturer Information

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality components for commercial vehicles. With a history of innovation and a strong reputation, Cummins is committed to producing reliable and efficient parts that meet the demands of heavy-duty applications. The company’s expertise in engine technology is reflected in the design and performance of components like the 3036996 Water Transfer Tube 8.

Conclusion

The Cummins 3036996 Water Transfer Tube is a vital component in the cooling system of heavy-duty trucks, ensuring efficient heat dissipation and maintaining optimal engine temperature. Its durable construction, key features, and role in truck operation contribute to the vehicle’s performance and longevity. Proper installation, maintenance, and understanding of its function are essential for the efficient operation of the cooling system.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2350 X101, Bulletin Number 4310640.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2350 X101, Bulletin Number 4310640.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2350 X101, Bulletin Number 4310640.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2350 X101, Bulletin Number 4310640.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2350 X101, Bulletin Number 4310640.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.