This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

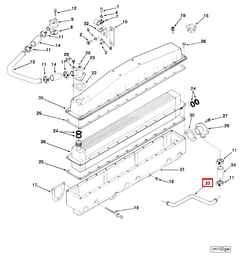

The Water Transfer Tube (Part #3037673) by Cummins is a component designed to facilitate the efficient transfer of coolant within heavy-duty truck systems. Cummins, a well-established manufacturer in the automotive industry, produces this part to enhance the performance and reliability of truck cooling systems.

Function and Operation

The Water Transfer Tube operates within the truck’s cooling system by directing coolant flow from the engine to the radiator and back. This process helps maintain optimal engine temperature, ensuring efficient operation and preventing overheating. The tube is positioned to connect critical components within the cooling system, allowing for seamless coolant circulation.

Key Features

The Water Transfer Tube is constructed from high-quality materials that ensure durability and resistance to corrosion. Its design includes precise fittings and connections that integrate smoothly with other components in the cooling system. The tube’s robust construction is tailored to withstand the high pressures and temperatures typical in heavy-duty truck engines.

Benefits

The Water Transfer Tube offers several advantages, including improved coolant flow which enhances engine performance. By ensuring consistent coolant circulation, the tube helps maintain engine temperature within safe limits, contributing to overall engine reliability. Additionally, the efficient design of the tube reduces the risk of coolant leaks, which can lead to engine damage if not addressed promptly.

Installation Process

Installing the Water Transfer Tube requires careful attention to detail to ensure proper function. Begin by locating the correct position within the cooling system, typically between the engine and the radiator. Secure the tube using the provided fittings, ensuring all connections are tight to prevent leaks. It is important to follow the manufacturer’s guidelines for torque specifications when tightening fittings to avoid over-tightening, which can damage the tube or connections.

Common Issues and Troubleshooting

Typical problems associated with the Water Transfer Tube include leaks and blockages. Leaks may occur due to loose fittings or corrosion, while blockages can result from debris within the coolant system. To diagnose issues, inspect the tube and connections for signs of wear or damage. If a leak is detected, tighten the fittings or replace any damaged sections. For blockages, flush the cooling system to remove debris and ensure smooth coolant flow.

Maintenance Tips

To ensure the longevity and optimal performance of the Water Transfer Tube, regular maintenance is recommended. This includes periodic inspection of the tube and connections for signs of wear or corrosion. It is also beneficial to flush the cooling system regularly to remove any buildup that could impede coolant flow. Additionally, monitoring the coolant level and condition can help identify potential issues before they become significant problems.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its wide range of products including engines, filtration, and power generation equipment. Founded in 1919, Cummins has built a reputation for quality and innovation, serving customers in over 190 countries. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of heavy-duty applications.

Water Transfer Tube (Part 3037673) in Cummins Engines

The Water Transfer Tube, identified by the part number 3037673, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

NH/NT 855 Engines

In the NH/NT 855 engines, the Water Transfer Tube (3037673) plays a pivotal role in the engine’s cooling mechanism. This engine series is known for its robust performance and reliability, often used in heavy-duty applications. The tube connects the water pump to the radiator, allowing coolant to flow through the system and absorb heat from the engine. Proper installation and maintenance of this part are essential to prevent overheating and ensure the longevity of the engine.

Grouping by Application

The Water Transfer Tube (3037673) is also utilized in other Cummins engine models that share similar design and operational principles. These engines, often found in industrial and commercial applications, benefit from the efficient heat transfer capabilities of this component. By ensuring a steady flow of coolant, the tube helps maintain the engine’s efficiency and reduces the risk of thermal stress.

Importance of the Water Transfer Tube

The Water Transfer Tube (3037673) is integral to the cooling system’s functionality. Its role in facilitating the movement of coolant is crucial for the engine’s overall performance. Any malfunction or degradation of this part can lead to significant issues, including engine overheating and potential damage. Regular inspection and timely replacement of the Water Transfer Tube are recommended to maintain the engine’s health and performance.

Role of Part 3037673 Water Transfer Tube in Engine Systems

The Water Transfer Tube (part 3037673) is integral to the efficient operation of several components within an engine system. It facilitates the movement of water between key parts, ensuring optimal performance and cooling.

Integration with Aftercooler Conversion Kit

When integrated with an Aftercooler Conversion Kit, the Water Transfer Tube plays a significant role in enhancing the efficiency of the aftercooling process. It ensures a consistent flow of water to the aftercooler, which is essential for reducing the temperature of the compressed air before it enters the engine. This results in improved engine performance and longevity.

Function in Aftercooler Plumbing

In the context of Aftercooler Plumbing, the Water Transfer Tube is responsible for maintaining a steady water supply to the aftercooler. This is vital for effective heat exchange, which in turn helps in maintaining the desired air temperature for combustion. Proper plumbing ensures that the water transfer is seamless, preventing any potential leaks or inefficiencies.

Connection to Aftercooler Water Outlet Tube

The Water Transfer Tube connects to the Aftercooler Water Outlet Tube, creating a continuous pathway for water circulation. This connection is essential for the aftercooler to function correctly, as it allows for the efficient removal of heat from the compressed air. The tube ensures that water is directed away from the aftercooler, preventing any buildup of heat and ensuring a consistent cooling effect.

Interaction with Intake Manifold

The Water Transfer Tube also interacts with the Intake Manifold by providing a regulated water flow that aids in the cooling of the intake air. This is particularly important in high-performance engines where the intake air temperature can significantly affect combustion efficiency. The tube ensures that the intake manifold receives a consistent supply of cool water, which helps in maintaining optimal air temperature for efficient combustion.

Conclusion

The Water Transfer Tube (Part #3037673) by Cummins is a vital component in the cooling systems of heavy-duty trucks and engines. Its role in facilitating efficient coolant flow ensures optimal engine temperature, enhancing performance and reliability. Regular maintenance and proper installation are crucial to prevent common issues such as leaks and blockages. By understanding the function and importance of this part, users can ensure the longevity and efficiency of their engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.