This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Water Transfer Tube (Part #3039283) manufactured by Cummins is a component designed to facilitate the efficient transfer of coolant within the engine cooling system of heavy-duty trucks. Its role is significant as it helps maintain the optimal operating temperature of the engine, ensuring reliable performance and longevity 4.

Basic Concepts and Functionality

The Water Transfer Tube operates on the fundamental principle of fluid dynamics, allowing coolant to circulate between different parts of the engine cooling system. This circulation is vital for dissipating heat generated by the engine, thereby preventing overheating. The tube connects various components within the cooling system, ensuring a continuous flow of coolant that absorbs heat from the engine and transfers it to the radiator for dissipation 1.

Purpose and Role in Truck Operation

In the operation of a heavy-duty truck, this Cummins part ensures that coolant is evenly distributed throughout the engine. This distribution is necessary for efficient combustion and to prevent thermal stress on engine components. By facilitating the movement of coolant, the tube contributes to the overall stability and performance of the truck’s engine 2.

Key Features

The Water Transfer Tube is constructed from durable materials that can withstand the high temperatures and pressures within the engine cooling system. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance its durability and resistance to wear and corrosion, ensuring long-term reliability in demanding operating conditions 3.

Benefits

Using the Cummins Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the efficiency of the cooling system. The durable construction of the tube contributes to its longevity, reducing the need for frequent replacements. Furthermore, by maintaining optimal engine temperature, the tube can contribute to overall engine efficiency and longevity, potentially reducing maintenance costs and downtime 4.

Installation and Integration

Proper installation of the Water Transfer Tube is important for the effective operation of the cooling system. It should be correctly positioned and securely fitted to prevent leaks and ensure efficient coolant flow. Following manufacturer guidelines during installation can help avoid common issues and ensure the tube functions as intended within the system 1.

Troubleshooting Common Issues

Common problems with Water Transfer Tubes include leaks and blockages. These issues can often be identified through visual inspection or by monitoring the performance of the cooling system. Troubleshooting may involve checking connections for tightness, inspecting the tube for signs of wear or damage, and ensuring that there are no obstructions in the coolant flow path. Addressing these issues promptly can help maintain the efficiency of the cooling system 2.

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and efficient operation of the Water Transfer Tube. This includes periodic inspections for signs of wear, corrosion, or leaks. It is also advisable to follow the manufacturer’s recommendations for replacement intervals, as prolonged use can lead to degradation of the tube’s material properties. Keeping the cooling system clean and free of contaminants can also contribute to the overall performance and lifespan of the tube 3.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer with a long history of producing high-quality automotive components. The company is particularly renowned for its contributions to the heavy-duty truck industry, offering a range of products designed to enhance performance, reliability, and efficiency. Cummins’ reputation for quality and innovation makes its components, including the Water Transfer Tube, a preferred choice for many in the industry 4.

Engine Compatibility with Water Transfer Tube Part 3039283

The Water Transfer Tube part number 3039283, manufactured by Cummins, is a component in the cooling systems of various engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient thermal management and preventing overheating.

L10 MECHANICAL Engines

The L10 MECHANICAL engine series is known for its robust design and reliability, often used in heavy-duty applications. The Water Transfer Tube part 3039283 is specifically engineered to fit seamlessly within the cooling system architecture of these engines. Its placement and design ensure optimal coolant flow, which is crucial for maintaining engine performance and longevity.

In the L10 MECHANICAL engines, the Water Transfer Tube connects the engine block to the radiator, allowing for the efficient transfer of heat from the engine to the cooling system. This part is integral to the engine’s cooling efficiency and overall operational stability 1.

Role of Part 3039283 Water Transfer Tube in Engine Systems

The Part 3039283 Water Transfer Tube is a component in the efficient operation of various engine systems, particularly in those involving aftercoolers. Its primary function is to facilitate the transfer of water within the aftercooler plumbing system, ensuring optimal cooling of the compressed air before it enters the engine.

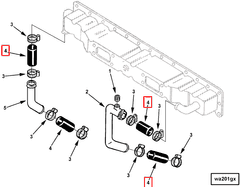

Integration with Aftercooler Plumbing

In the aftercooler plumbing system, the Water Transfer Tube connects to the aftercooler water (ACW) lines. This connection allows for the circulation of water through the aftercooler core, where it absorbs heat from the compressed air. The cooled air then proceeds to the engine, enhancing combustion efficiency and reducing the risk of overheating 2.

Contribution to Overall Plumbing System

Beyond its specific role in the aftercooler, the Water Transfer Tube is a vital link in the broader plumbing system of the engine. It ensures that water is effectively routed to and from the aftercooler, maintaining a consistent flow that is essential for the system’s performance. This component works in tandem with other plumbing elements, such as hoses, fittings, and valves, to create a cohesive water management system within the engine 3.

Enhancing Aftercooler Water Functionality

The efficiency of the aftercooler water system is significantly influenced by the Water Transfer Tube. By providing a reliable pathway for water circulation, it supports the aftercooler’s ability to regulate air temperature. This, in turn, contributes to the overall stability and performance of the engine, particularly under varying operational conditions 4.

Conclusion

The Part 3039283 Water Transfer Tube plays a key role in the aftercooler plumbing and the broader engine plumbing system. Its effective integration and function are essential for maintaining the optimal performance and longevity of the engine. Regular maintenance and proper installation are crucial to ensure the tube’s efficiency and durability, contributing to the overall reliability and performance of heavy-duty truck engines.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ ↩ ↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ ↩ ↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ ↩ ↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.