This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

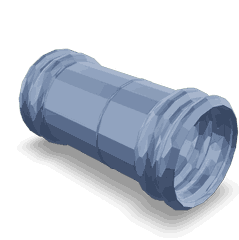

The Cummins 3049174 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the engine 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between various components of the engine cooling system. Its function is to ensure that coolant is evenly distributed, which helps in dissipating heat generated by the engine. The tube operates by channeling coolant from the radiator, through the thermostat, and into the engine block, where it absorbs heat before returning to the radiator for cooling 2.

Purpose of the 3049174 Water Transfer Tube

The 3049174 Water Transfer Tube plays a role in the cooling system by connecting the radiator to the engine block and thermostat. This connection ensures that coolant circulates effectively, absorbing heat from the engine and transferring it to the radiator where it can be dissipated. The tube’s design allows for seamless integration with these components, contributing to the overall efficiency of the cooling process 3.

Key Features

The 3049174 Water Transfer Tube is constructed from durable materials that resist corrosion and withstand high temperatures. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to handle the pressure of the cooling system, enhancing its performance and reliability.

Benefits

The 3049174 Water Transfer Tube offers several benefits, including improved cooling efficiency due to its design and material composition. Its durability ensures long-term performance, even in demanding operating conditions. The tube’s reliability contributes to the overall stability of the engine cooling system, reducing the risk of overheating and related engine issues.

Installation Process

Installing the 3049174 Water Transfer Tube requires careful preparation and the use of appropriate tools. The process involves disconnecting the old tube, cleaning the connection points, and securely fitting the new tube into place. It is important to follow manufacturer guidelines to ensure a proper fit and to prevent leaks. Torque specifications for fastening should be adhered to for a secure installation.

Common Issues and Troubleshooting

Common issues with the 3049174 Water Transfer Tube may include leaks, blockages, or corrosion. Troubleshooting these issues involves inspecting the tube for signs of wear or damage, ensuring connections are tight, and checking for proper coolant flow. Solutions may range from cleaning and repairing minor damage to replacing the tube if it is severely compromised.

Maintenance Tips

Regular maintenance of the 3049174 Water Transfer Tube is important for prolonging its lifespan. This includes periodic inspections for signs of wear or leaks, cleaning the tube and connections to prevent blockages, and following manufacturer recommendations for replacement intervals. Proper maintenance ensures the cooling system operates efficiently and reduces the risk of engine overheating.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its components, including the 3049174 Water Transfer Tube.

Role of Part 3049174 Water Transfer Tube in Engine Systems

The 3049174 Water Transfer Tube is an integral component in the efficient operation of various engine systems, particularly those involving the circulation of coolant. This component facilitates the smooth transfer of water between several key components, ensuring optimal engine performance and temperature regulation.

Integration with Manifold and Water Systems

The Water Transfer Tube connects to the manifold and water system, allowing for the consistent flow of coolant. This connection is essential for maintaining the engine’s temperature, as it ensures that the coolant is evenly distributed throughout the engine block and cylinder heads. The tube’s precise fit and secure connection prevent leaks and ensure that the coolant system operates under the correct pressure.

Interaction with Thermostat Housing

In conjunction with the thermostat housing, the Water Transfer Tube plays a significant role in temperature control. The thermostat housing regulates the flow of coolant based on the engine’s temperature. The tube ensures that coolant reaches the thermostat housing efficiently, allowing for accurate temperature readings and appropriate coolant flow adjustments.

Mounting and Plumbing Connections

The Water Transfer Tube is also designed to interface with the thermostat housing mounting, water manifold, water manifold mounting, and water manifold plumbing. These connections are vital for the structural integrity and functional efficiency of the coolant system. The tube’s role in these mountings and plumbing setups ensures that coolant is directed correctly through the engine, preventing hotspots and ensuring even cooling across all engine components.

Water Mounting Manifold and Plumbing Manifold

Finally, the tube connects to the water mounting manifold and water plumbing manifold. These manifolds distribute coolant to various parts of the engine, including the radiator and other cooling components. The Water Transfer Tube’s reliable performance in these connections is essential for the overall effectiveness of the engine’s cooling system, contributing to prolonged engine life and enhanced performance.

Conclusion

The Cummins 3049174 Water Transfer Tube is a vital component in the cooling systems of commercial trucks, ensuring efficient coolant circulation and temperature regulation. Its durable construction, precise design, and reliable performance contribute to the overall efficiency and longevity of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018.

↩ -

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014.

↩ -

Electrical Systems and Mechatronics, Second Edition, Michael Hilgers, Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.