This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

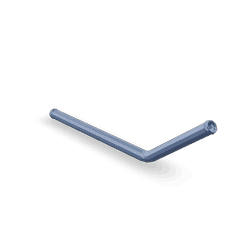

The Water Transfer Tube (Part #3056693) manufactured by Cummins is a component designed to play a significant role in the cooling system of heavy-duty trucks. It contributes to maintaining engine efficiency and longevity by ensuring that the engine operates within optimal temperature ranges 1.

Basic Concepts of Water Transfer Tubes

Water transfer tubes are integral to the engine cooling system. They function by circulating coolant throughout the engine, which absorbs heat and transfers it away from critical components. This process helps maintain the engine’s temperature, ensuring it operates efficiently and extends its lifespan 2.

Purpose and Functionality

The Water Transfer Tube serves a vital function in the operation of a truck by circulating coolant. This circulation helps maintain optimal engine temperature and prevents overheating, which can lead to engine damage. By ensuring a consistent flow of coolant, the tube supports the engine’s performance and reliability 3.

Key Features

The Cummins Water Transfer Tube is characterized by its durable construction and precise engineering. It is designed to be compatible with specific truck models, ensuring a secure fit and effective performance. The tube’s materials and design contribute to its reliability and efficiency in the cooling system.

Benefits

Using the Cummins Water Transfer Tube offers several benefits. It enhances engine cooling efficiency, which is crucial for maintaining optimal engine performance. The tube’s durable construction reduces the risk of coolant leaks, contributing to the overall reliability of the cooling system. Additionally, its precise engineering ensures compatibility and effective operation within the specified truck models.

Installation Process

Installing the Water Transfer Tube requires following a step-by-step procedure to ensure a secure and effective fit. The process involves using the necessary tools, observing precautions, and adhering to best practices. Proper installation is key to ensuring the tube functions correctly within the cooling system.

Maintenance and Troubleshooting

Routine maintenance practices can help prolong the lifespan of the Water Transfer Tube. Regular inspections for signs of wear or damage are recommended. Troubleshooting common issues such as leaks or blockages involves identifying the source of the problem and taking appropriate corrective actions to restore the tube’s functionality.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality engine components. With a strong reputation for reliability and performance, Cummins continues to innovate and provide solutions that meet the demands of heavy-duty applications. The company’s commitment to quality is evident in its product offerings, including the Water Transfer Tube.

Water Transfer Tube (Part 3056693) Compatibility with Cummins Engines

The Water Transfer Tube, identified by part number 3056693, is a critical component in the cooling systems of various Cummins engines. This part is designed to facilitate the transfer of coolant between different parts of the engine, ensuring efficient thermal management and preventing overheating.

K19 Engines

The K19 engine series, known for its robust performance and reliability, incorporates the Water Transfer Tube to maintain optimal coolant flow. This part is essential in managing the thermal dynamics of the engine, ensuring that the coolant is evenly distributed and that the engine operates within safe temperature limits.

KTA19GC CM558 Engines

Similarly, the KTA19GC CM558 engine benefits from the Water Transfer Tube’s role in coolant management. This engine, often used in heavy-duty applications, relies on the efficient transfer of coolant to maintain performance and longevity. The Water Transfer Tube ensures that the coolant reaches all necessary areas, preventing localized overheating and extending the engine’s operational life.

Grouping of Engines

The K19 and KTA19GC CM558 engines, while distinct in their specific applications, share a commonality in their need for efficient coolant management. The Water Transfer Tube (part 3056693) is integral to both engine types, ensuring that the coolant is effectively circulated throughout the engine. This part’s compatibility with these engines underscores its importance in maintaining the thermal balance and overall health of the engine.

Role of Part 3056693 Water Transfer Tube in Engine Systems

The part 3056693 Water Transfer Tube is an essential component in the efficient operation of various engine systems, particularly those involving coolant management and heating functionalities.

Integration with Coolant Heater Starting System

In the coolant heater starting system, the Water Transfer Tube facilitates the movement of coolant from the coolant heater to the engine block. This ensures that the engine reaches optimal operating temperature more quickly, reducing wear and tear during startup and enhancing overall engine performance. The tube’s precise fit and durable construction are designed to withstand the pressures and temperatures associated with this system, ensuring reliable operation.

Function within Coolant Heater System

Within the coolant heater system, the Water Transfer Tube plays a key role in circulating heated coolant throughout the engine. This is particularly important in colder climates where maintaining engine temperature is vital for efficient operation and longevity. The tube ensures that the heated coolant is distributed evenly, preventing hotspots and ensuring consistent temperature across the engine components.

Role in Coolant Heater Plumbing

In the context of coolant heater plumbing, the Water Transfer Tube is integral to the overall coolant flow management. It connects various components of the coolant system, including the coolant heater, thermostat, and engine block. This interconnection ensures that the coolant is effectively circulated, maintaining the engine’s thermal stability. The tube’s design allows for minimal resistance to coolant flow, enhancing the efficiency of the heating system and contributing to the engine’s reliable performance.

Auxiliary Integration with Aid Systems

Additionally, the Water Transfer Tube may be utilized in auxiliary systems designed to aid in engine performance, such as pre-heating systems or supplementary cooling circuits. In these applications, the tube ensures that coolant is efficiently transferred to and from these auxiliary components, supporting the primary coolant system and enhancing overall engine reliability and performance.

Conclusion

The Cummins Water Transfer Tube (Part #3056693) is a critical component in the cooling systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in circulating coolant ensures that the engine operates within optimal temperature ranges, enhancing performance and longevity. The tube’s durable construction, precise engineering, and compatibility with specific engine models make it a reliable and efficient solution for coolant management. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the engine’s thermal stability and overall health.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.