This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

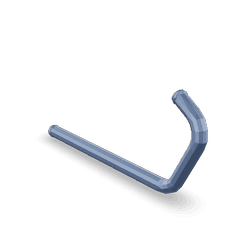

The Water Transfer Tube, identified by Part #3058373, is a component manufactured by Cummins, a well-established name in the automotive industry. This tube is integral to the cooling system of heavy-duty trucks, facilitating the efficient transfer of coolant between various components to maintain optimal engine temperature 1.

Function and Operation

The Water Transfer Tube operates within the truck’s cooling system by channeling coolant from the engine to the radiator and other cooling components. Its role is to ensure a consistent flow of coolant, which absorbs heat from the engine and dissipates it through the radiator. This process is vital for maintaining engine temperature within safe operating limits, thereby supporting overall engine performance and longevity 2.

Key Features

The Water Transfer Tube is designed with specific characteristics to enhance its functionality and durability. Constructed from high-quality materials, it is resistant to corrosion and capable of withstanding the high pressures and temperatures typical of heavy-duty truck engines. Its design ensures a secure fit and reliable connection between components, minimizing the risk of leaks and ensuring efficient coolant transfer 3.

Benefits

Incorporating the Water Transfer Tube into a truck’s cooling system offers several advantages. It promotes improved coolant flow, which enhances the cooling efficiency of the system. This efficient cooling contributes to maintaining engine performance and can potentially extend the engine’s operational life by preventing overheating. The tube’s robust construction also ensures reliability under demanding conditions, reducing the likelihood of system failures 4.

Installation and Compatibility

Proper installation of the Water Transfer Tube is crucial for ensuring optimal performance. It should be fitted according to the manufacturer’s guidelines, which may include specific torque settings for connections and ensuring all seals are intact. Compatibility with various truck models should be verified to ensure the tube meets the specific requirements of the cooling system it is intended to serve 5.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube involves regular inspections for signs of wear, corrosion, or leaks. Ensuring connections are tight and free from debris can prevent common issues such as coolant leaks. If a leak is detected, it is important to address it promptly to avoid potential engine damage due to insufficient cooling. Regular maintenance contributes to the longevity and efficiency of the cooling system 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to delivering high-quality components for commercial vehicles. Their products are known for reliability, performance, and durability, making them a preferred choice for heavy-duty truck manufacturers and operators 7.

Role of Part 3058373 Water Transfer Tube in Engine Systems

The Part 3058373 Water Transfer Tube is an integral component in the efficient operation of several engine systems, particularly those involving coolant circulation and temperature regulation.

Integration with Coolant Heater Starting System

In the coolant heater starting system, the Water Transfer Tube facilitates the movement of heated coolant from the coolant heater to the engine block. This ensures that the engine reaches optimal operating temperature more quickly during startup, especially in colder environments. The efficient transfer of heated coolant reduces the strain on the engine during startup and enhances overall engine performance and longevity 8.

Function within the Coolant Heater System

Within the coolant heater system, the Water Transfer Tube plays a significant role in maintaining consistent coolant temperature. By ensuring a steady flow of heated coolant, it helps prevent thermal stress on engine components and promotes uniform temperature distribution throughout the engine block. This consistent temperature management is essential for the reliable operation of the engine, particularly in varying climatic conditions 9.

Contribution to Coolant Heater Plumbing

In the context of coolant heater plumbing, the Water Transfer Tube is a key element that connects various components of the coolant system. It ensures that the coolant flows seamlessly from the heater to the engine and other critical areas that require temperature regulation. The tube’s design and material are tailored to withstand the pressures and temperatures associated with coolant systems, ensuring durable and efficient performance 10.

Conclusion

The Water Transfer Tube part number 3058373, manufactured by Cummins, is a vital component in the cooling systems of various engines. Its role in facilitating efficient coolant transfer and temperature regulation is crucial for maintaining engine performance and longevity. Proper installation, maintenance, and understanding of its function within different engine systems are essential for ensuring optimal engine operation.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSB6.7 CM2150 B109. Bulletin Number 4326166.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.