This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

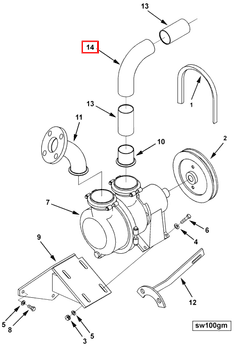

Introduction

The Cummins 3060827 Water Transfer Tube is designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. It ensures that the engine maintains optimal operating temperatures, which is essential for the longevity and performance of the engine. This part is integral to the cooling system, helping to dissipate heat generated during engine operation 1.

Function and Operation

The Water Transfer Tube directs coolant flow from the engine block to the radiator or other cooling components. As the engine runs, it generates heat, which is absorbed by the coolant circulating through the engine passages. This tube provides a conduit for the coolant to travel from the engine to the radiator, where the heat is dissipated into the air. This continuous circulation helps maintain a stable engine temperature, preventing overheating and ensuring efficient engine operation 2.

Key Features

The Cummins 3060827 Water Transfer Tube is constructed from durable materials, typically a combination of metal and rubber, which allows it to withstand the high temperatures and pressures within the engine cooling system. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance durability and resist wear over time. These features contribute to the tube’s ability to perform reliably under demanding conditions 3.

Benefits

The advantages of the Water Transfer Tube include improved coolant flow, which enhances the engine’s cooling efficiency. By ensuring a consistent and uninterrupted flow of coolant, the tube helps protect the engine from overheating, which can lead to severe damage. Furthermore, the tube’s robust construction and design contribute to increased reliability, making it suitable for use in heavy-duty applications where durability is paramount.

Installation and Compatibility

Proper installation of the Water Transfer Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and that the tube is properly aligned within the cooling system. Compatibility with specific engine models and systems should be verified to ensure optimal performance and integration within the existing cooling infrastructure.

Maintenance and Troubleshooting

Routine maintenance of the Water Transfer Tube involves regular inspection for signs of wear, leaks, or damage. It is advisable to check the tube during scheduled engine maintenance intervals and replace it if any issues are detected. Common problems may include coolant leaks, which can often be traced to deteriorated connections or a compromised tube. Addressing these issues promptly can prevent more significant problems and ensure the continued efficiency of the cooling system.

Performance Impact

The Water Transfer Tube contributes to overall engine performance by playing a role in the cooling system’s ability to maintain consistent operating temperatures. Efficient coolant flow facilitated by the tube helps prevent overheating, which can adversely affect engine performance and longevity. By ensuring that the engine operates within its optimal temperature range, the tube supports the engine’s efficiency and reliability.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its extensive product range, which is designed to meet the demanding requirements of various applications.

Role of Part 3060827 Water Transfer Tube in Engine Systems

The 3060827 Water Transfer Tube is an integral component in the efficient operation of marine and industrial engine systems. Its primary function is to facilitate the movement of raw water from the sea water pump to various engine components that require cooling.

Integration with the Sea Water Pump

The sea water pump is responsible for drawing in raw water from the surrounding environment. The Water Transfer Tube connects directly to the outlet of this pump, ensuring a seamless transition of water flow. This connection is essential for maintaining the pump’s efficiency, as it prevents backflow and ensures that the water is directed precisely where it is needed.

Role in Cooling Systems

Once the raw water is pumped through the Water Transfer Tube, it is typically routed to the engine’s cooling system. This system may include components such as the heat exchanger, where the raw water absorbs heat from the engine’s coolant. The Water Transfer Tube ensures that the raw water reaches the heat exchanger at the correct pressure and flow rate, optimizing the heat exchange process.

Connection to Other Components

Beyond the heat exchanger, the Water Transfer Tube may also supply raw water to other engine components that require cooling, such as the turbocharger or the aftercooler. In these applications, the tube ensures that a consistent flow of cool water is maintained, which is vital for the efficient operation and longevity of these components.

Importance in Maintenance and Efficiency

The Water Transfer Tube plays a significant role in the overall maintenance and efficiency of the engine system. By ensuring a reliable and uninterrupted flow of raw water, it helps to prevent overheating and potential damage to engine components. Regular inspection and maintenance of the tube are recommended to ensure it remains in optimal condition, contributing to the engine’s performance and durability.

Conclusion

The Cummins 3060827 Water Transfer Tube is a critical component in the cooling systems of heavy-duty trucks and marine/industrial engines. Its role in facilitating efficient coolant and raw water flow ensures that engines operate within optimal temperature ranges, thereby enhancing performance, reliability, and longevity. Proper installation, regular maintenance, and understanding its integration within the engine system are essential for maximizing the benefits of this part.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.