This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

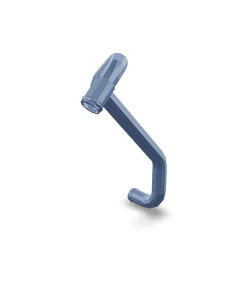

The Cummins 3065130 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of heavy-duty trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the engine.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of the engine cooling system. Its function is to ensure that coolant is evenly distributed, which helps in dissipating heat generated by the engine. This process is crucial for maintaining engine temperature within safe operating limits, thereby preventing overheating and potential engine damage 1.

Purpose of the Cummins 3065130 Water Transfer Tube

The Cummins 3065130 Water Transfer Tube specifically serves to transfer coolant between the engine and the radiator. This transfer is integral to the cooling system’s operation, as it ensures that the coolant absorbs heat from the engine and then releases it into the atmosphere via the radiator. This continuous cycle helps in regulating engine temperature effectively.

Key Features

The Cummins 3065130 Water Transfer Tube is constructed from durable materials that can withstand the high temperatures and pressures within the engine cooling system. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance its durability under demanding conditions.

Benefits

The use of the Cummins 3065130 Water Transfer Tube offers several benefits. It provides improved coolant flow, which enhances the efficiency of the cooling system. This results in better engine protection against overheating. Furthermore, its robust construction increases the reliability of the cooling system, especially in heavy-duty applications where the engine is subjected to rigorous use 2.

Installation Process

Installing the Cummins 3065130 Water Transfer Tube requires careful preparation. The engine cooling system should be drained of old coolant, and any old gaskets or seals should be removed. The tube should be installed according to the manufacturer’s instructions, ensuring that all connections are tight and secure. Using the appropriate tools and following a step-by-step process will help in achieving a proper installation.

Maintenance Tips

To ensure the optimal performance of the Cummins 3065130 Water Transfer Tube, regular maintenance is recommended. This includes inspecting the tube for any signs of wear or damage, checking for leaks, and ensuring that all connections remain tight. Cleaning the tube and its connections as part of routine coolant system maintenance will help in preventing buildup that could impede coolant flow.

Troubleshooting Common Issues

Common issues with Water Transfer Tubes may include leaks or blockages. If a leak is detected, it is important to identify the source and repair or replace the affected section. Blockages can be addressed by flushing the cooling system to remove any debris or contaminants that may be obstructing coolant flow. Regular inspections can help in identifying and resolving these issues promptly.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for producing high-quality engine components and systems. With a history of innovation and commitment to excellence, Cummins has built a reputation for reliability and performance in the heavy-duty truck sector. Their components, including the 3065130 Water Transfer Tube, are designed to meet the demanding requirements of modern engines 3.

Compatibility with Cummins Engines

The Water Transfer Tube, identified by the part number 3065130, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the transfer of coolant between different sections of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

N14 CELECT Engine

In the N14 CELECT engine, the Water Transfer Tube (3065130) plays a pivotal role in the engine’s cooling system. It connects the water pump to the radiator, allowing coolant to flow from the pump to the radiator where it is cooled before being recirculated back into the engine. This tube is integral to the engine’s ability to manage heat effectively, thereby enhancing performance and longevity.

N14 MECHANICAL Engine

Similarly, in the N14 MECHANICAL engine, the Water Transfer Tube (3065130) is essential for the proper functioning of the cooling system. It ensures that coolant is efficiently circulated from the water pump to the radiator, where it is cooled before being returned to the engine. This component is crucial for maintaining the engine’s operational temperature and preventing overheating, which can lead to significant engine damage.

Grouping of Engines

Both the N14 CELECT and N14 MECHANICAL engines rely on the Water Transfer Tube (3065130) for effective cooling. The design and placement of this tube are tailored to fit these specific engine models, ensuring compatibility and optimal performance. The tube’s role in facilitating the flow of coolant is vital for both engine types, highlighting the importance of using the correct part for maintenance and repairs.

Role in Engine Systems

The Water Transfer Tube, identified by part number 3065130, is integral to the efficient operation of various engine systems. This component facilitates the movement of coolant between different sections of the engine, ensuring consistent temperature regulation and optimal performance.

Integration with the Intake Manifold

The intake manifold is a key component in the engine’s air induction system, responsible for distributing air evenly to each cylinder. The Water Transfer Tube works in conjunction with the intake manifold to maintain a stable temperature environment. By circulating coolant through the manifold, the tube helps prevent overheating, which can lead to warped components and reduced engine efficiency.

Function in Coolant Circulation

In engine systems, the Water Transfer Tube is part of a network of tubes and passages designed to circulate coolant effectively. It connects to other water transfer tubes, creating a continuous loop that ensures coolant reaches all critical areas of the engine block and cylinder heads. This systematic circulation is essential for dissipating heat generated during combustion, thereby protecting sensitive engine components from thermal stress.

Enhancing Engine Reliability

By ensuring that coolant is evenly distributed, the Water Transfer Tube contributes to the overall reliability of the engine. Consistent coolant flow prevents hot spots, which can cause uneven expansion and contraction of metal parts, leading to mechanical failures. The tube’s role in maintaining a uniform temperature across the engine enhances longevity and performance.

Supporting Efficient Combustion

Efficient combustion within an engine relies on precise temperature control. The Water Transfer Tube aids in this by helping to maintain the optimal operating temperature for the engine. This not only improves fuel efficiency but also reduces emissions by ensuring that the combustion process is as complete as possible.

Conclusion

In summary, the Water Transfer Tube (part 3065130) plays a significant role in the thermal management of engine systems, working alongside the intake manifold and other coolant pathways to ensure the engine operates within its designed temperature range. Regular maintenance and proper installation are crucial for the optimal performance and longevity of this component.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.