3071228

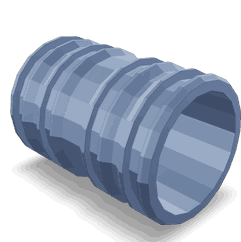

Water Transfer Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Water Transfer Tubes

Water transfer tubes are essential components in engine systems, responsible for circulating coolant to maintain optimal operating temperatures. These tubes prevent engine overheating, which can cause severe damage and reduced efficiency. In heavy-duty engines like those from Cummins, water transfer tubes are crucial due to the higher stress and demands on these engines 1.

Cummins, a leader in the diesel engine industry since 1919, is renowned for its quality and innovation. Their commitment to excellence is evident in every component they produce, including the water transfer tube part #3071228 2.

Basic Concepts of Water Transfer Tubes

Water transfer tubes direct coolant from the engine block to the cylinder head and other critical components, dissipating heat generated during combustion. This circulation is vital for maintaining engine performance and longevity. These tubes are typically made from durable materials like high-grade aluminum or copper, offering excellent thermal conductivity and corrosion resistance 3.

Purpose and Role of the Cummins Water Transfer Tube Part #3071228

The Cummins water transfer tube part #3071228 is designed to integrate seamlessly with Cummins engines’ cooling systems. This part ensures efficient coolant flow, preventing overheating and maintaining engine temperature and performance. Proper coolant management is vital for the reliable and efficient operation of commercial trucks 4.

Troubleshooting and Maintenance of the Cummins Water Transfer Tube Part #3071228

Recognizing signs of a failing water transfer tube, such as coolant leaks, engine overheating, and reduced performance, is crucial for maintaining engine health. Potential causes of failure include corrosion, physical damage, or wear and tear.

Regular inspection and maintenance are recommended to extend the life of the water transfer tube. This includes checking for leaks, ensuring secure connections, and verifying that the coolant system is free of contaminants. Proactive maintenance can help identify issues before they lead to more significant problems.

For troubleshooting, inspect the tube for visible damage or leaks, check the integrity of connections and fittings, and follow Cummins’ recommended procedures for repair or replacement to ensure efficient engine operation.

Expert Insights and Best Practices

Industry experts emphasize the importance of regular maintenance and timely replacements of water transfer tubes. Proactive maintenance can significantly reduce the risk of engine failure and extend engine lifespan.

For fleet operators, integrating water transfer tube maintenance into regular service schedules is crucial to avoid unexpected downtime and ensure trucks remain operational, contributing to overall fleet efficiency.

Cummins’ Commitment to Quality and Innovation

Cummins’ manufacturing approach is characterized by stringent quality control processes and a commitment to innovation. Their water transfer tubes are produced using advanced technologies and materials to ensure durability and performance. Cummins continually invests in research and development to enhance the reliability and efficiency of their components.

Customer support and resources are readily available for Cummins parts, including the water transfer tube part #3071228. Technical support, educational materials, and training programs are provided to help technicians and fleet operators maintain their equipment effectively.

Water Transfer Tube (Part 3071228) Compatibility with Cummins Engines

The Water Transfer Tube, identified by the part number 3071228, is a critical component in the cooling system of various Cummins engines. This part facilitates the transfer of coolant between different sections of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

G855

The G855 engine utilizes the Water Transfer Tube, which is integral to the engine’s cooling system, ensuring proper coolant flow to prevent overheating and maintain engine efficiency.

N14 CELECT PLUS and N14 MECHANICAL

Both the N14 CELECT PLUS and N14 MECHANICAL engines are equipped with the Water Transfer Tube. This component is essential for the proper functioning of the engine’s cooling system, providing a reliable pathway for coolant circulation. The design of the Water Transfer Tube ensures it fits seamlessly into the architecture of these engines, contributing to their overall performance and longevity.

QSN14 CM876 N103 and QSNT14 CM876 N102

The Water Transfer Tube is also compatible with the QSN14 CM876 N103 and QSNT14 CM876 N102 engines. These engines benefit from the precise engineering of the Water Transfer Tube, which ensures efficient coolant transfer and helps maintain the engine’s operational integrity. The design of this part is tailored to fit these specific engine models, providing a robust solution for coolant management.

Role of Part 3071228 Water Transfer Tube in Engine Systems

The part 3071228 Water Transfer Tube is essential for the efficient operation of engine systems, particularly in the context of the rocker lever and water manifold.

In the engine system, the rocker lever plays a significant role in the valve operation mechanism. It amplifies the motion from the camshaft to open and close the engine’s valves. The Water Transfer Tube, part 3071228, ensures that the rocker lever and other components remain at optimal operating temperatures. It facilitates the circulation of coolant, preventing overheating and ensuring smooth operation.

The water manifold is another component where the Water Transfer Tube is integral. The water manifold is responsible for distributing coolant to various parts of the engine. The Water Transfer Tube connects to the water manifold, allowing for a consistent flow of coolant. This connection is vital for maintaining uniform temperatures across the engine, which is necessary for efficient performance and longevity of the engine components.

Conclusion

The Cummins water transfer tube part #3071228 is a vital component in maintaining the performance and reliability of Cummins engines. Proper maintenance and timely troubleshooting are essential to ensure the efficient operation of commercial trucks. By following best practices and leveraging Cummins’ resources, mechanics and engineers can help ensure their engines remain in optimal condition, contributing to the overall success of their operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.