This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

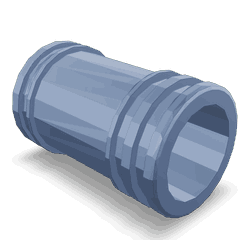

The Cummins 3175267 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the cooling system of commercial trucks. Its role is significant in maintaining optimal engine temperature, which is vital for the performance and longevity of the vehicle.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit within the cooling system that allows coolant to flow between the engine and the radiator. This tube operates by channeling coolant from the engine, where it absorbs heat, to the radiator, where the heat is dissipated into the air. This continuous circulation helps to regulate engine temperature and prevent overheating 1.

Purpose of the 3175267 Water Transfer Tube

The Cummins 3175267 Water Transfer Tube is integral to the truck’s cooling system. It enables the movement of coolant between the engine and radiator, ensuring that heat generated by the engine is effectively transferred away. This process is fundamental to maintaining engine temperature within safe operating limits, thereby supporting engine efficiency and durability 2.

Key Features

The Cummins 3175267 Water Transfer Tube is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures typical of commercial truck engines. The tube’s design includes features that enhance coolant flow and reduce the risk of leaks, contributing to its performance and durability 3.

Benefits

The Cummins 3175267 Water Transfer Tube offers several advantages. It provides improved coolant flow, which enhances the efficiency of the cooling system. This results in better engine protection against overheating, especially under demanding conditions. Additionally, the tube’s design and materials contribute to increased reliability and longevity, reducing the need for frequent replacements.

Installation Process

Installing the Cummins 3175267 Water Transfer Tube involves several steps to ensure a secure and effective fit. Preparatory steps include cleaning the installation area and ensuring all mating surfaces are free of debris. The installation requires specific tools, and following the manufacturer’s guidelines is recommended to achieve the best results. Proper alignment and securing of the tube are critical to prevent leaks and ensure efficient coolant flow.

Common Issues and Troubleshooting

Water Transfer Tubes can encounter issues such as leaks or blockages. These problems can arise from wear and tear, improper installation, or debris within the cooling system. Troubleshooting methods include inspecting the tube for signs of damage or wear, checking for proper alignment and secure fitting, and ensuring the cooling system is free of contaminants. Addressing these issues promptly can prevent more severe engine problems.

Maintenance Tips

Regular maintenance of the Cummins 3175267 Water Transfer Tube is important for its longevity and efficient operation. This includes periodic inspections for signs of wear, leaks, or blockages. Cleaning the tube and the surrounding area can prevent the buildup of debris that might obstruct coolant flow. Following the manufacturer’s recommended maintenance schedule can help ensure the tube continues to function effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and performance is evident in its engine components, including the Cummins 3175267 Water Transfer Tube.

Water Transfer Tube (Part 3175267) in Cummins Engines

The Water Transfer Tube, identified by the part number 3175267, is a critical component in several Cummins engine models. This part is integral to the engine’s cooling system, facilitating the transfer of coolant between different parts of the engine to maintain optimal operating temperatures.

K38 Engines

In the K38 engine series, the Water Transfer Tube ensures efficient coolant flow, which is essential for maintaining engine performance and longevity. This part is designed to withstand the high pressures and temperatures typical of diesel engines, providing a reliable pathway for coolant circulation.

K50 Engines

Similarly, in the K50 engine series, the Water Transfer Tube plays a pivotal role in the engine’s cooling mechanism. The design of this part in the K50 series is optimized to handle the specific demands of this engine model, ensuring that the coolant is distributed evenly and effectively throughout the engine.

Common Features Across Models

While the specific design and placement of the Water Transfer Tube may vary slightly between different engine models, its fundamental purpose remains consistent. It is engineered to provide a durable and leak-proof connection, critical for the engine’s overall cooling efficiency. The material used in the construction of this part is selected for its ability to resist corrosion and degradation, ensuring long-term reliability and performance.

By integrating this part into their engine designs, Cummins ensures that their engines can operate efficiently under a wide range of conditions, maintaining the integrity of the cooling system and protecting the engine from overheating.

Role of Part 3175267 Water Transfer Tube in Engine Systems

The Water Transfer Tube (Part 3175267) is an essential component in the efficient operation of various engine systems, particularly in turbocharged and intercooled setups. Its primary function is to facilitate the movement of coolant between different parts of the engine, ensuring optimal temperature regulation and performance.

Integration with the Aftercooler

In turbocharged engines, the Aftercooler plays a significant role in cooling the compressed air before it enters the combustion chamber. The Water Transfer Tube connects to the Aftercooler and the Aftercooler Kit, allowing coolant to flow through the aftercooler core. This process reduces the temperature of the compressed air, increasing its density and ultimately enhancing engine performance.

Connection to the Intake Manifold

The Intake Manifold is another critical component where the Water Transfer Tube finds its application. By connecting to the intake manifold, the tube ensures that the incoming air-fuel mixture is at an optimal temperature. This connection is particularly important in high-performance engines where even minor temperature variations can affect combustion efficiency and power output.

Role in the Plumbing System

The Water Transfer Tube is a vital part of the engine’s Plumbing system. It acts as a conduit for coolant, linking various components such as the Water Inlet Connection and other coolant passages. This ensures a consistent flow of coolant throughout the engine, maintaining uniform temperature across different parts.

Contribution to Performance Parts

When considering Performance Parts and Performance Part Kits, the Water Transfer Tube is often included to enhance the cooling efficiency of modified engines. In high-performance applications, the increased stress on engine components necessitates robust cooling solutions. The tube’s role in these kits is to provide reliable coolant transfer, supporting the enhanced performance and durability of the engine.

Interaction with the Camshaft and PDC

Although the Camshaft and PDC (Powertrain Control Module) are not directly connected to the Water Transfer Tube, the tube’s efficient coolant transfer indirectly supports these components. By maintaining optimal engine temperatures, the tube helps in reducing thermal stress on the camshaft and ensures that the PDC receives accurate temperature readings for effective engine management.

Conclusion

In summary, the Water Transfer Tube (Part 3175267) is a fundamental component in the coolant system of modern engines. Its role in connecting and facilitating coolant flow between critical components like the aftercooler, intake manifold, and various plumbing connections ensures that the engine operates within its optimal temperature range, thereby supporting both performance and reliability.

-

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.