This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

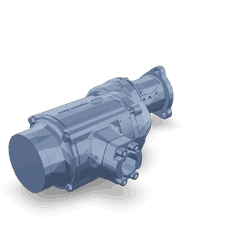

The Cummins 4332176 Air Starting Motor is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the start-up of large diesel engines using compressed air, a method that is both efficient and reliable. This motor is significant in the operation of heavy-duty trucks as it ensures that engines can be started quickly and smoothly, even under challenging conditions.

Basic Concepts of Air Starting Motors

An air starting motor is a device that uses compressed air to turn over a diesel engine during the start-up process. Unlike traditional electric starters, air starting motors rely on the force of compressed air to initiate engine rotation. This system operates on the principle that compressed air, when released, expands and creates a force that can be harnessed to turn the engine’s crankshaft. In the context of heavy-duty trucks, this method is particularly effective for starting large diesel engines, which require a significant amount of torque to overcome the inertia of their heavy components 1.

Purpose of the Cummins 4332176 Air Starting Motor

The Cummins 4332176 Air Starting Motor plays a role in the operation of a truck by initiating engine start-up using compressed air. When the start signal is given, the motor engages with the flywheel of the engine, using the force of compressed air to turn it over. This action allows the engine to reach the necessary speed for combustion to occur, thereby starting the engine. The use of compressed air ensures that the engine can be started reliably, even in conditions where an electric starter might struggle, such as in cold weather or when the battery is weak 2.

Key Features

The Cummins 4332176 Air Starting Motor is characterized by several key features that enhance its performance and reliability. Its design is robust, with a focus on durability to withstand the harsh conditions often encountered in heavy-duty truck operations. The motor is constructed using high-quality materials that are resistant to wear and corrosion, ensuring long-term operation. Additionally, it features a precise engineering design that allows for efficient use of compressed air, maximizing the force applied to the engine’s flywheel.

Benefits

Using the Cummins 4332176 Air Starting Motor offers several advantages. It provides improved starting reliability, ensuring that the engine can be started under a wide range of conditions. This reliability reduces the wear on the engine, as the air starting motor applies a consistent and controlled force to the flywheel, minimizing the risk of damage. Furthermore, the motor enhances the overall performance of the truck, allowing for quicker and more efficient start-ups, which is particularly beneficial in heavy-duty applications.

Installation and Integration

When installing the Cummins 4332176 Air Starting Motor, it is important to consider its compatibility with the truck’s existing starting system and other components. Proper integration ensures that the motor functions efficiently and effectively. Guidelines for installation include ensuring that the motor is securely mounted and that all connections to the compressed air system are properly sealed to prevent leaks. It is also important to verify that the motor is correctly aligned with the engine’s flywheel to ensure smooth engagement during start-up.

Troubleshooting and Maintenance

Common issues with the Cummins 4332176 Air Starting Motor may include leaks in the compressed air system, wear on the motor’s components, or electrical issues with the start signal. Troubleshooting steps involve checking for leaks, inspecting the motor for signs of wear, and ensuring that the electrical connections are secure and functioning correctly. Regular maintenance practices, such as cleaning the motor and checking for wear on moving parts, can help ensure optimal performance and longevity.

Performance in Various Conditions

The Cummins 4332176 Air Starting Motor is designed to perform reliably under a variety of operating conditions. It is capable of starting engines in extreme temperatures, both hot and cold, and at high altitudes where the air is thinner. Its robust design and efficient use of compressed air make it well-suited for heavy-duty applications, where reliability and performance are paramount.

Comparison with Other Starting Systems

When compared to other starting systems, such as electric starters, the Cummins 4332176 Air Starting Motor offers distinct advantages. While electric starters are common and widely used, they may struggle in extreme conditions or when the battery is weak. Air starting motors, on the other hand, provide a more consistent and reliable starting force, making them ideal for heavy-duty applications. However, they require a compressed air system, which adds complexity to the truck’s design.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and efficiency of vehicles and equipment.

Air Starting Motor 4332176 Compatibility with Cummins Engines

The Air Starting Motor 4332176, manufactured by Cummins, is a critical component in the starting systems of several Cummins engine models. This part is specifically designed to work seamlessly with the QSK95 series engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113 variants.

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Air Starting Motor 4332176 is engineered to provide reliable and efficient starting power. It is designed to withstand the demanding conditions these engines operate under, ensuring consistent performance and longevity.

In these engines, the Air Starting Motor 4332176 interfaces with the engine’s air intake system, utilizing compressed air to initiate the engine’s starting sequence. This design minimizes wear on the engine’s battery and starter motor, extending the overall lifespan of these critical components.

The compatibility of the Air Starting Motor 4332176 with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines is a testament to Cummins’ commitment to providing high-quality, reliable parts that enhance engine performance and durability.

Role of Part 4332176 Air Starting Motor in Engine Systems

The part 4332176 Air Starting Motor is an essential component in the operation of various engine systems, particularly in marine and industrial applications where air start systems are prevalent. This motor is designed to convert pneumatic energy into mechanical energy, facilitating the initial rotation of the engine’s crankshaft.

Integration with Engine Components

-

Crankshaft: The Air Starting Motor directly engages with the crankshaft, providing the necessary torque to initiate engine rotation. This engagement is typically achieved through a gear or direct coupling mechanism, ensuring a smooth and efficient start-up process.

-

Cylinders: As the crankshaft rotates, the pistons within the cylinders begin their compression stroke. The Air Starting Motor ensures that the engine reaches the required rotational speed to commence combustion, which is vital for the engine’s operation.

-

Valve Train: The rotation of the crankshaft also influences the valve train, opening and closing the intake and exhaust valves in synchronization with the piston movement. This coordination is essential for the proper intake of air and fuel and the expulsion of exhaust gases.

-

Flywheel: The Air Starting Motor contributes to building the rotational inertia of the flywheel. This inertia helps maintain engine momentum during the start-up phase, aiding in a stable and consistent engine operation once the combustion process begins.

-

Lubricating System: During the start-up phase, the rotation induced by the Air Starting Motor helps circulate lubricants throughout the engine. This circulation is important for reducing friction between moving parts and ensuring the engine components are adequately protected from wear.

-

Exhaust System: As the engine starts, the Air Starting Motor assists in the initial expulsion of exhaust gases through the exhaust system. This process is important for clearing the cylinders and preparing the engine for continuous operation.

-

Control Systems: Modern engines often incorporate electronic control units (ECUs) that monitor and regulate the start-up process. The Air Starting Motor works in conjunction with these control systems to ensure a precise and controlled engine start, enhancing overall performance and reliability.

In summary, the part 4332176 Air Starting Motor plays a significant role in the coordinated function of various engine components, ensuring a smooth and efficient start-up process. Its integration with the crankshaft, cylinders, valve train, flywheel, lubricating system, exhaust system, and control systems underscores its importance in the overall engine operation.

Conclusion

The Cummins 4332176 Air Starting Motor is a critical component for the reliable and efficient start-up of heavy-duty diesel engines. Its robust design, efficient use of compressed air, and compatibility with Cummins engines make it an invaluable part of the engine system. By understanding its role and benefits, operators and maintenance personnel can ensure optimal performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.