This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

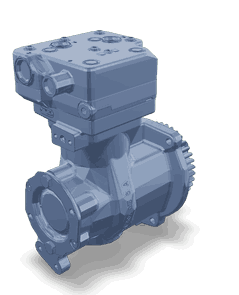

The Cummins 4318216 Air Compressor is a component designed for use in commercial trucks. It serves to generate and maintain the compressed air necessary for various truck systems. Its role is significant in ensuring the efficient and safe operation of commercial vehicles, particularly in relation to braking, suspension, and other pneumatic systems 1.

Basic Concepts of Air Compressors

Air compressors are mechanical devices that convert power into potential energy stored in pressurized air. They operate by drawing in air, compressing it, and storing it in a tank until needed. In commercial trucking, air compressors are vital for powering the braking system, suspension, and other pneumatic controls. They ensure that these systems function correctly under varying load and operational conditions 2.

Role of the Cummins 4318216 Air Compressor in Truck Operation

This Cummins part plays a specific role in the operation of a commercial truck. It provides the compressed air required for the braking system, which is crucial for safe vehicle operation. Additionally, it supports the air suspension system, contributing to ride comfort and vehicle stability. The compressor also powers other pneumatic systems on the truck, ensuring they operate efficiently 3.

Key Features

The Cummins 4318216 is characterized by several key features. Its design is robust, built to withstand the demanding conditions of commercial truck operations. The compressor is known for its efficiency, providing reliable performance with minimal energy consumption. It incorporates technological advancements that enhance its durability and operational effectiveness.

Benefits of Using the Cummins 4318216 Air Compressor

Using this part offers several benefits. It contributes to improved truck performance by ensuring that pneumatic systems operate efficiently. The compressor’s reliability reduces the likelihood of system failures, enhancing safety. Its efficiency also leads to lower operational costs, making it a valuable component for commercial truck fleets.

Installation and Integration

Proper installation and integration of the Cummins 4318216 into a commercial truck are important for optimal performance. This process involves ensuring that the compressor is correctly mounted, connected to the truck’s air system, and that all electrical connections are secure. Consideration should be given to the truck’s specific requirements and the compressor’s compatibility with existing systems.

Maintenance and Troubleshooting

Maintaining the Cummins 4318216 is important for its longevity and performance. Regular checks, cleaning, and lubrication are recommended to prevent buildup and ensure smooth operation. Troubleshooting common issues, such as leaks or unusual noises, can often be addressed through routine maintenance practices, ensuring the compressor continues to function effectively.

Performance and Efficiency

The performance and efficiency of the Cummins 4318216 have a direct impact on fuel consumption, operational costs, and overall truck performance. Its efficient operation helps in reducing unnecessary fuel usage, contributing to lower operational costs. The compressor’s reliable performance ensures that truck systems operate as intended, enhancing overall vehicle efficiency.

Safety Considerations

When using the Cummins 4318216, safety considerations are paramount. Proper handling and operation of the compressor are important to prevent accidents. Emergency procedures should be in place for situations where the compressor malfunctions or if there is a sudden loss of air pressure. Adhering to safety guidelines ensures the safe operation of the truck and the protection of its occupants.

Environmental Impact

The environmental impact of using the Cummins 4318216 is an important consideration. Its efficiency in compressing air contributes to reducing emissions by ensuring that truck systems operate optimally with minimal energy waste. This efficiency is a step towards more sustainable trucking operations, aligning with broader environmental goals.

Cummins Corporation Overview

Cummins Corporation, the manufacturer of the 4318216, has a long-standing history in the automotive and commercial vehicle industry. The company is known for its commitment to innovation and quality, providing solutions that enhance the performance and efficiency of vehicles. Cummins’ role in the industry is characterized by its dedication to advancing technology and meeting the needs of its customers.

Cummins AIR COMPRESSOR Part 4318216 Compatibility

The Cummins AIR COMPRESSOR part number 4318216 is designed to fit seamlessly with several models of Cummins engines, ensuring optimal performance and reliability. This part is specifically engineered to work with the ISX CM570, ISX CM870, and ISX CM871 engines.

For the ISX CM570 and ISX CM870 engines, the AIR COMPRESSOR part 4318216 is a critical component that ensures the engine’s air intake system functions efficiently. Its design allows for effective air compression, which is essential for maintaining the engine’s power output and overall performance.

Similarly, the ISX CM871 engine benefits from the AIR COMPRESSOR part 4318216, which is tailored to meet the specific demands of this engine model. This part ensures that the air intake system operates smoothly, contributing to the engine’s reliability and longevity.

By using the Cummins AIR COMPRESSOR part 4318216, owners of these engines can expect enhanced performance and durability, making it a valuable addition to their maintenance and repair routines.

Role of Part 4318216 Air Compressor in Engine Systems

The air compressor, identified by part number 4318216, is an integral component within various engine systems, facilitating the delivery of pressurized air essential for multiple functions. Its primary role is to compress ambient air, which is then utilized in several key processes.

Fuel Injection Systems

In fuel injection systems, the air compressor supplies pressurized air that mixes with fuel before entering the combustion chamber. This pressurized air enhances the atomization of fuel, leading to a more efficient and complete combustion process. The improved air-fuel mixture results in better engine performance and reduced emissions.

Turbocharging and Supercharging

When integrated into turbocharged or supercharged engines, the air compressor works in tandem with the turbocharger or supercharger to increase the volume of air entering the engine. This additional air allows for more fuel to be burned, thereby boosting engine power output. The compressor ensures that the increased airflow is at the optimal pressure, maintaining engine efficiency and performance.

Pneumatic Systems

In pneumatic systems, the air compressor provides the necessary pressurized air to operate various components such as brakes, clutches, and actuators. The consistent and reliable supply of compressed air ensures that these systems function smoothly and respond promptly to operator commands.

Cabin Pressurization

For engines powering aircraft, the air compressor plays a vital role in cabin pressurization. It supplies compressed air to the environmental control system, which regulates the pressure and temperature within the cabin. This ensures a comfortable and safe environment for passengers and crew during flight.

Aftertreatment Systems

In modern engines equipped with aftertreatment systems, the air compressor contributes to the efficiency of components like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems. Pressurized air aids in the regeneration process of the DPF and ensures that the SCR system effectively reduces nitrogen oxides (NOx) emissions.

Cooling Systems

The air compressor also assists in engine cooling by providing pressurized air to the intercoolers in turbocharged engines. This helps in reducing the temperature of the compressed air before it enters the combustion chamber, enhancing engine efficiency and preventing overheating.

Conclusion

In summary, the air compressor (part 4318216) is a versatile component that enhances the performance, efficiency, and reliability of various engine systems through the provision of pressurized air. Its integration into fuel injection, turbocharging, pneumatic, cabin pressurization, aftertreatment, and cooling systems underscores its critical role in modern engine technology.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.