The Cummins 2871292 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as the alternator, water pump, and air conditioning compressor. Proper belt tension is essential for the optimal performance and longevity of these components 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It functions by applying consistent pressure to the belt, which helps in reducing slippage and wear. Maintaining proper belt tension is important for ensuring that the belts drive their respective components efficiently, which in turn contributes to the overall performance and reliability of the engine 2.

Purpose of the Cummins 2871292 Belt Tensioner

The Cummins 2871292 Belt Tensioner plays a role in the operation of a truck by maintaining optimal belt tension. This ensures that power is transmitted efficiently from the engine to various accessories. By keeping the belts properly tensioned, it helps in reducing the risk of belt slippage, which can lead to inefficient operation and increased wear on both the belts and the components they drive 3.

Key Features

The Cummins 2871292 Belt Tensioner is characterized by its robust design and the use of high-quality materials. These features contribute to its performance and durability. The tensioner is engineered to withstand the demanding conditions found in commercial truck engines, ensuring reliable operation over time. Its design includes provisions for easy installation and maintenance, which are important considerations for fleet managers and technicians.

Benefits of Using the Cummins 2871292 Belt Tensioner

Using the Cummins 2871292 Belt Tensioner offers several advantages. It contributes to improved engine performance by ensuring that belts operate at the correct tension. This results in reduced wear on the belts and the components they drive, leading to enhanced reliability and longevity of the engine system. Additionally, proper belt tension helps in minimizing noise and vibration, which can be indicative of belt slippage or misalignment.

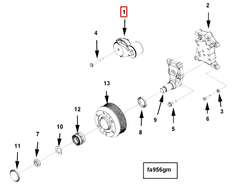

Installation Process

Installing the Cummins 2871292 Belt Tensioner involves several steps to ensure correct fitting. It is important to use the appropriate tools and follow the manufacturer’s guidelines. The process includes removing the old tensioner, if applicable, and positioning the new tensioner in its place. Careful attention should be paid to aligning the tensioner correctly and securing it in place to ensure it functions as intended.

Maintenance and Troubleshooting

Maintaining the Cummins 2871292 Belt Tensioner involves regular inspection to check for signs of wear or failure. It is important to look for indications such as cracks, excessive wear, or noise during operation, which may suggest the need for replacement or adjustment. Troubleshooting common issues, such as belt slippage or tensioner noise, often involves checking the tensioner’s alignment and condition, and making adjustments or replacements as necessary.

Common Issues and Solutions

Frequent problems associated with belt tensioners include noise, slippage, and premature wear. These issues can often be addressed by ensuring the tensioner is correctly installed and maintained. Solutions may involve adjusting the tensioner, replacing worn belts, or addressing alignment issues. Preventive measures include regular inspections and maintenance to identify and address potential issues before they lead to more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history is marked by innovation and a focus on meeting the needs of its customers. The Cummins 2871292 Belt Tensioner is part of its extensive product line, designed to meet the high standards expected in commercial truck applications.

Belt Tensioner Part 2871292 Compatibility with Cummins Engines

The Belt Tensioner part number 2871292, manufactured by Cummins, is a critical component in maintaining the proper tension of the engine’s serpentine belt. This part is designed to ensure that the belt operates efficiently and reliably across a range of Cummins engine models. Below is a detailed description of its compatibility with various Cummins engines:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The Belt Tensioner part 2871292 is compatible with the ISX series engines, which include the ISX CM570, ISX CM870, ISX CM871, ISX12/ISX11.9 CM2250, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The Belt Tensioner part 2871292 is also compatible with the QSX series engines, including the QSX11.9 CM2250 ECF, QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105. These engines are designed for high-performance applications and are often equipped with advanced emission control features.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The Belt Tensioner part 2871292 fits the X15 series engines, which include the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B. These engines are engineered for durability and efficiency, making them suitable for a variety of demanding applications.

By ensuring that the Belt Tensioner part 2871292 is correctly installed, engine owners can maintain optimal belt tension, which is crucial for the efficient operation of the engine’s ancillary components, such as the alternator, water pump, and air conditioning compressor.

Role of Part 2871292 Belt Tensioner in Engine Systems

The part 2871292 Belt Tensioner is integral to maintaining the proper function and efficiency of various engine components. It ensures that the belts driving these components are kept at the correct tension, which is essential for their optimal performance.

Interaction with Fan Drive

The fan drive is a component responsible for controlling the speed of the engine cooling fan. It adjusts the fan speed based on the engine’s temperature, ensuring efficient cooling without unnecessary power consumption. The belt tensioner plays a significant role here by maintaining the appropriate tension on the belt that drives the fan. This ensures that the fan drive operates smoothly and effectively, preventing slippage that could lead to inefficient cooling or increased wear on the belt.

Contribution to Fan Drive Mounting

The fan drive mounting is the structure that secures the fan drive to the engine. Proper belt tension is vital for the stability and reliability of this mounting. The belt tensioner ensures that the belt remains taut, which reduces the strain on the fan drive mounting. This not only enhances the durability of the mounting but also ensures that the fan drive remains securely in place, contributing to the overall stability and performance of the engine cooling system.

Conclusion

The Cummins 2871292 Belt Tensioner is a critical component in the maintenance and efficiency of commercial truck engines. By ensuring proper belt tension, this Cummins part contributes to the reliable operation of engine-driven accessories, enhances engine performance, and extends the longevity of both the belts and the components they drive. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.