3691282

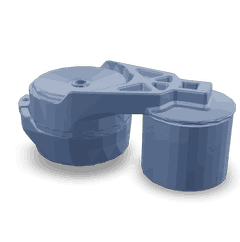

Belt Tensioner

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3691282 Belt Tensioner is designed to maintain the proper tension of the serpentine belt in commercial trucks, ensuring efficient operation and reliability of the truck’s engine system.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in engine systems to keep the serpentine belt at the correct tension. It applies consistent pressure to the belt, facilitating the smooth operation of driven accessories such as the alternator, water pump, and air conditioning compressor. Proper belt tension prevents slippage, reduces wear on both the belt and pulleys, and ensures efficient power transfer within the engine system 1.

Role of the 3691282 Belt Tensioner in Truck Operation

This Cummins part ensures that the serpentine belt remains taut, which is necessary for the effective operation of driven accessories. The tensioner automatically adjusts to maintain the correct tension, accommodating changes in belt length due to temperature variations and wear 2.

Key Features of the 3691282 Belt Tensioner

The 3691282 is typically made from high-strength materials to withstand the rigors of commercial truck operation. Its mechanism involves a spring-loaded arm that applies consistent pressure to the belt. Unique attributes may include a dampening system to reduce vibrations and noise, contributing to a smoother operation 3.

Benefits of Using the 3691282 Belt Tensioner

The advantages provided by this part include improved efficiency in the accessory drive system, reduced wear on belts and pulleys due to consistent tension, and enhanced reliability. These benefits contribute to the overall performance and longevity of the truck’s engine system.

Troubleshooting Common Issues with Belt Tensioners

Identifying and addressing common problems associated with belt tensioners involves recognizing symptoms such as unusual noises, visible belt wear, or accessories failing to operate correctly. Diagnostic procedures may include inspecting the tensioner for signs of damage, testing the spring mechanism for proper function, and checking the belt for proper tension. Potential solutions range from simple adjustments to replacement of the tensioner or belt.

Maintenance Tips for the 3691282 Belt Tensioner

To ensure optimal performance and longevity of the 3691282, regular inspection routines are recommended. This includes checking for signs of wear or damage, ensuring the spring mechanism operates correctly, and verifying that the belt tension is within the manufacturer’s specifications. Lubrication guidelines may vary, but keeping moving parts clean and free of debris is generally beneficial. Replacement intervals depend on the operating conditions and should be in accordance with the manufacturer’s recommendations or based on the condition of the part.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications.

Belt Tensioner Part 3691282 Compatibility with Cummins Engines

The Belt Tensioner part number 3691282, manufactured by Cummins, is designed to fit a range of Cummins engines. This part plays a role in maintaining the tension of the engine’s serpentine belt, ensuring optimal performance and longevity of the belt and related components.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

This Belt Tensioner is engineered to ensure that the serpentine belt remains properly tensioned, preventing slippage and maintaining the efficiency of the engine’s ancillary systems. Proper installation and maintenance of this component are essential for the longevity and performance of the engine.

Role of Part 3691282 Belt Tensioner in Engine Systems

The 3691282 is an integral component in maintaining the efficiency and reliability of engine systems by ensuring the proper tension of the drive belt. This, in turn, facilitates the seamless operation of various engine-driven accessories.

Interaction with the Drive System

In engine systems, the drive belt is responsible for transferring power from the crankshaft to essential components such as the alternator, water pump, and power steering pump. The Belt Tensioner, part 3691282, plays a significant role here by maintaining the correct tension on the drive belt. This ensures that the belt does not slip or become overly tight, which could lead to inefficient power transfer or premature wear of the belt and pulleys.

Contribution to Fan Operation

The engine cooling fan is another component that relies on the drive belt for operation. The Belt Tensioner ensures that the belt remains properly tensioned as it wraps around the fan pulley. This is particularly important under varying engine loads and speeds, as the tension needs to be consistent to prevent the belt from jumping off the pulley or causing excessive noise and vibration.

Overall System Integration

By maintaining the appropriate tension, the Belt Tensioner contributes to the smooth and efficient operation of the entire engine system. It helps in reducing the stress on the drive belt and pulleys, thereby enhancing the longevity of these components. Additionally, proper belt tension ensures that the engine-driven accessories receive a consistent power supply, which is essential for their optimal performance.

Conclusion

The Cummins 3691282 Belt Tensioner is a critical component for maintaining the efficiency and reliability of commercial truck engine systems. By ensuring the proper tension of the serpentine belt, it facilitates the smooth operation of driven accessories and contributes to the overall performance and longevity of the engine system. Regular maintenance and proper installation are essential for maximizing the benefits of this part.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.