This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Belt Tensioner 3638012 by Cummins is a component designed to ensure the proper functioning of drive belts in commercial trucks. Its role is significant in maintaining the efficiency and reliability of the truck’s engine system. This tensioner is part of Cummins’ commitment to providing high-quality parts that enhance the performance and longevity of commercial vehicles.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to maintain the correct tension on drive belts. These belts are responsible for driving various engine accessories such as the alternator, water pump, and air conditioning compressor. Proper tension is essential for the efficient transfer of power and to prevent belt slippage, which can lead to decreased performance and potential damage to the engine components. Regular maintenance of belt tension is therefore important for the overall health of the engine system 1.

Purpose of the 3638012 Belt Tensioner

The 3638012 Belt Tensioner plays a role in the operation of a truck by maintaining the correct tension on the drive belts. This ensures that the belts run smoothly and efficiently, which is vital for the proper functioning of engine accessories. By keeping the belts at the optimal tension, the tensioner helps to reduce wear and tear, prevent slippage, and ensure consistent performance of the engine system.

Key Features

The 3638012 Belt Tensioner is designed with several features that enhance its performance. It is constructed from durable materials to withstand the rigors of commercial truck operation. The design includes a spring-loaded mechanism that automatically adjusts the tension on the belts as they stretch or wear over time. This self-adjusting feature ensures that the belts remain at the correct tension without the need for manual adjustment.

Benefits of Using the 3638012 Belt Tensioner

Using the 3638012 Belt Tensioner provides several advantages. It contributes to improved engine performance by ensuring that the drive belts operate efficiently. This can lead to better fuel efficiency and reduced strain on the engine. Additionally, the tensioner helps to reduce wear on the belts, which can extend their lifespan and reduce the frequency of replacements. The enhanced reliability of the engine system is another benefit, as proper belt tension is crucial for the consistent operation of engine accessories 2.

Installation and Compatibility

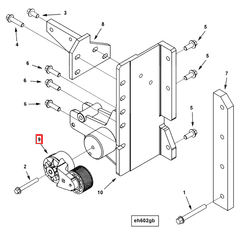

Proper installation of the 3638012 Belt Tensioner is important to ensure its effective operation. It is designed to be compatible with specific truck models, and installation should follow the manufacturer’s guidelines to ensure correct fitment and function. Attention to any specific requirements or considerations for different truck models is necessary to maintain the integrity of the engine system.

Troubleshooting Common Issues

Common problems associated with belt tensioners include noise, slippage, or failure. These issues can often be traced back to improper tension, wear, or damage to the tensioner or belts. Troubleshooting steps may involve checking the tensioner for signs of wear, ensuring that the belts are correctly aligned and not damaged, and verifying that the tensioner is functioning as intended. Addressing these issues promptly can help to maintain the performance and reliability of the engine system.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3638012 Belt Tensioner. This includes periodic inspection of the tensioner and belts for signs of wear or damage, ensuring that the belts are properly tensioned, and replacing any worn or damaged components as necessary. Adhering to these maintenance tips can help to prevent issues and ensure the continued efficient operation of the engine system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to excellence is reflected in its parts, such as the 3638012 Belt Tensioner, which are engineered to enhance the performance and reliability of commercial trucks.

Belt Tensioner Part 3638012 Compatibility with Cummins Engines

The Belt Tensioner part number 3638012, manufactured by Cummins, is designed to fit a variety of their engine models. This part is crucial for maintaining the proper tension of the engine’s belt, ensuring efficient power transmission and reducing wear on the belt and associated components.

ISX15 Series

- ISX15 CM2250

- ISX15 CM2350 X101

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

QSK Series

- QSK45 CM500

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK78 CM500

QST Series

- QST30 CM2350 T101

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

Role of Part 3638012 Belt Tensioner in Engine Systems

The part 3638012 Belt Tensioner is an essential component in maintaining the proper function and efficiency of various engine systems. It ensures that the belts driving key components are kept at the correct tension, which is vital for their performance and longevity.

Interaction with the Drive System

In the drive system, the Belt Tensioner works in conjunction with the drive belts to maintain consistent tension. This is important for the efficient transfer of power from the engine to auxiliary components. Without proper tension, belts can slip, leading to reduced efficiency and potential damage to the drive system.

Ensuring Alternator Efficiency

The alternator relies on a drive belt to function correctly. The Belt Tensioner plays a significant role here by keeping the belt taut. This ensures that the alternator receives a steady and sufficient amount of power to generate electricity for the vehicle’s electrical systems. Inconsistent tension can lead to alternator inefficiencies, affecting the vehicle’s overall electrical performance.

Fan System Integration

The engine cooling fan is another component driven by a belt. The Belt Tensioner ensures that the belt driving the fan maintains the correct tension. This is important for the fan’s ability to effectively cool the engine, preventing overheating and ensuring optimal engine performance.

Mounting and Stability

The mounting of the Belt Tensioner is designed to provide stability and reduce vibrations. This is important for the longevity of the belts and the components they drive. A well-mounted tensioner contributes to a smoother operation of the engine systems, reducing wear and tear on both the belts and the driven components.

Comprehensive System Support

Overall, the Belt Tensioner supports a range of engine systems by ensuring that all drive belts are maintained at the optimal tension. This not only enhances the performance of individual components like the alternator and fan but also contributes to the overall efficiency and reliability of the engine system.

Conclusion

The 3638012 Belt Tensioner by Cummins is a critical component in the maintenance and efficiency of commercial truck engine systems. Its design and features ensure that drive belts are kept at the optimal tension, contributing to the reliable operation of engine accessories and the overall performance of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.