This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

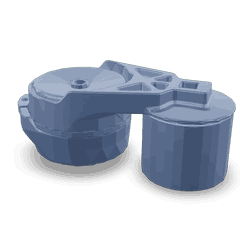

The Cummins 3691281 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant in ensuring the efficient operation of various engine components that rely on belt-driven systems.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep belts at the correct tension. It operates by applying consistent pressure to the belt, which helps in reducing slippage and wear. Proper tension ensures that belts drive components like the alternator, water pump, and air conditioning compressor effectively 1.

Purpose of the Cummins 3691281 Belt Tensioner

The Cummins 3691281 Belt Tensioner plays a role in the operation of a truck by maintaining optimal belt tension for various engine components. This ensures that belts operate efficiently without excessive slippage or wear, contributing to the overall reliability and performance of the engine system 2.

Key Features

The Cummins 3691281 Belt Tensioner is characterized by several key features that enhance its performance and durability. These include a robust design, the use of high-quality materials, and unique characteristics that ensure it can withstand the demanding conditions of commercial truck applications 3.

Benefits of Using the Cummins 3691281 Belt Tensioner

Using the Cummins 3691281 Belt Tensioner offers several advantages. These include improved engine efficiency due to reduced belt slippage, decreased wear on belts leading to longer service intervals, and enhanced reliability in demanding truck applications. Its design contributes to the overall performance and longevity of the engine system.

Installation Process

Installing the Cummins 3691281 Belt Tensioner requires following a step-by-step process to ensure correct fitment and function. This includes preparing the engine compartment, aligning the tensioner with the belt and pulleys, and securing it in place. Specific considerations may include ensuring the tensioner is properly aligned and that all fasteners are tightened to the manufacturer’s specifications.

Troubleshooting Common Issues

Common problems associated with belt tensioners include noise, slippage, or premature wear. Troubleshooting these issues may involve inspecting the tensioner for signs of damage or wear, checking the belt for proper tension and condition, and ensuring all components are correctly aligned and secured. Solutions may range from adjusting the tensioner to replacing worn components.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3691281 Belt Tensioner, routine maintenance practices are recommended. This includes regular inspection of the tensioner and belts for signs of wear or damage, and following manufacturer guidelines for replacement intervals. Proper maintenance contributes to the efficient operation of the engine system.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to producing high-quality components for commercial vehicles. With a history of innovation and reliability, Cummins components are widely used in the commercial trucking industry, contributing to the performance and durability of trucks worldwide.

Role of Part 3691281 Belt Tensioner in Engine Systems

The Part 3691281 Belt Tensioner is an essential component in maintaining the proper function of various engine-driven accessories. It ensures that the belts driving these accessories are kept at the correct tension, which is vital for their efficient operation.

Interaction with the Drive System

In the engine’s drive system, the Belt Tensioner works in conjunction with the drive belt to maintain consistent tension. This is important for the smooth transfer of power from the engine to components such as the alternator and the fan. Proper tension prevents slippage, which can lead to inefficient power transmission and potential damage to the belt or the driven components.

Ensuring Alternator Efficiency

The alternator is a key component that relies on the drive belt for operation. The Belt Tensioner ensures that the belt remains taut as it wraps around the alternator pulley. This tautness is necessary for the alternator to generate electricity efficiently. Without proper tension, the alternator may not spin at the required speed, leading to inadequate charging of the battery and potential electrical system failures.

Fan Operation and Cooling System

The engine-driven fan, which helps in cooling the engine by drawing air through the radiator, also depends on the drive belt. The Belt Tensioner plays a role in keeping the belt properly tensioned on the fan pulley. This ensures that the fan operates at the correct speed, providing adequate cooling to prevent the engine from overheating.

Secure Mounting for Stability

The mounting points for the Belt Tensioner are designed to provide a stable and secure attachment to the engine. This stability is important for maintaining the correct alignment and tension of the belt across all pulleys it engages with. Proper mounting ensures that the tensioner can effectively perform its role without undue stress or movement, which could otherwise lead to belt wear or failure.

Summary of Component Interaction

In summary, the Part 3691281 Belt Tensioner is integral to the operation of the drive system, ensuring that components like the alternator and fan receive consistent and efficient power transmission via the drive belt. Its role in maintaining belt tension is fundamental to the reliable operation of these engine-driven accessories.

Conclusion

The Cummins 3691281 Belt Tensioner is a vital component in the engine systems of commercial trucks, ensuring the efficient operation of belt-driven accessories. Its robust design, high-quality materials, and proper maintenance contribute to the overall performance and reliability of the engine system.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 (6th ed.). Oxford University Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.