This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

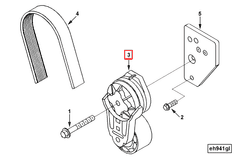

The Cummins 3917440 Belt Tensioner is a component designed to maintain the proper tension on drive belts within commercial truck engines. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as alternators, water pumps, and air conditioning compressors 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep drive belts at the correct tension. It functions by applying consistent pressure to the belt, which helps in reducing slippage and wear. Maintaining proper belt tension is important for the efficient transfer of power from the engine to the driven accessories, ensuring they operate within their designed parameters 2.

Purpose of the Cummins 3917440 Belt Tensioner

This Cummins part plays a role in the operation of a truck by maintaining the correct tension on drive belts. This ensures that the belts remain in optimal contact with the pulleys they drive, which is important for the reliable operation of engine accessories. Proper tensioning helps in minimizing belt slippage, reducing wear, and enhancing the overall performance and longevity of the drive belt system 1.

Key Features

The 3917440 is characterized by several design elements and materials that enhance its performance. It is constructed using durable materials that can withstand the high temperatures and dynamic loads present in a truck engine environment. The design incorporates features that allow for easy adjustment and maintenance, ensuring that the belt tension can be fine-tuned as needed.

Benefits of Using the Cummins 3917440 Belt Tensioner

Using this part offers several advantages. It contributes to improved belt life by ensuring consistent tension, which reduces the risk of premature wear and failure. Enhanced engine performance is another benefit, as properly tensioned belts can transfer power more efficiently. Additionally, the design of the tensioner can lead to reduced maintenance requirements, as it is built to operate reliably under demanding conditions 1.

Installation Process

Installing the 3917440 involves several steps. First, the old tensioner, if present, should be removed. This may require loosening bolts and disconnecting any electrical connections. The new tensioner is then positioned in place, ensuring that it aligns correctly with the belt and pulleys. Tools such as wrenches and possibly a belt tensioning tool may be required. It is important to follow the manufacturer’s instructions closely to ensure proper installation.

Troubleshooting Common Issues

Common problems associated with belt tensioners include noise, belt slippage, and wear. Noise can often be traced to a loose or worn tensioner, while slippage may indicate incorrect tension or a worn belt. Wear on the tensioner or belt can lead to decreased performance and eventual failure. Troubleshooting steps may involve inspecting the tensioner and belt for signs of wear, adjusting the tension as needed, or replacing worn components 2.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and efficient operation of the 3917440. This includes periodic inspection of the tensioner and belts for signs of wear or damage, ensuring that the belt tension is correct, and replacing belts according to the manufacturer’s recommendations or when signs of wear are evident. Keeping the tensioner and surrounding components clean can also contribute to its reliable operation 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of commercial applications.

Belt Tensioner 3917440 Compatibility with Cummins Engines

The Belt Tensioner part number 3917440, manufactured by Cummins, is designed to fit a variety of their engines. This part is integral in maintaining the correct tension on the engine’s serpentine belt, ensuring optimal performance and longevity of the belt and associated components.

Cummins 4B3.9 Engines

The 3917440 Belt Tensioner is compatible with the Cummins 4B3.9 engines. This engine model is known for its reliability and efficiency, often used in various industrial applications.

Cummins 6B5.9 Engines

Similarly, the 3917440 Belt Tensioner is suitable for the Cummins 6B5.9 engines. These engines are widely recognized for their robust performance and are commonly found in heavy-duty applications.

Cummins 6C8.3 Engines

The 3917440 Belt Tensioner also fits the Cummins 6C8.3 engines. These engines are designed for high-performance applications, providing the necessary power and efficiency for demanding tasks.

Cummins B5.9 G Engines

The Belt Tensioner part number 3917440 is also compatible with the Cummins B5.9 G engines. These engines are engineered for durability and are often used in various industrial and agricultural settings.

Cummins B5.9 GAS PLUS CM556 Engines

The 3917440 Belt Tensioner is designed to fit the Cummins B5.9 GAS PLUS CM556 engines. These engines are known for their advanced technology and efficiency, making them suitable for a wide range of applications.

Cummins C8.3 G Engines

The 3917440 Belt Tensioner is also compatible with the Cummins C8.3 G engines. These engines are built for performance and are often used in heavy-duty applications.

Cummins G8.3 Engines

The 3917440 Belt Tensioner fits the Cummins G8.3 engines. These engines are designed for high-performance and are commonly used in demanding industrial environments.

Cummins ISB CM550 Engines

The Belt Tensioner part number 3917440 is suitable for the Cummins ISB CM550 engines. These engines are known for their reliability and efficiency, making them a popular choice for various applications.

Cummins ISC CM554 Engines

The 3917440 Belt Tensioner is also compatible with the Cummins ISC CM554 engines. These engines are engineered for durability and are often used in heavy-duty applications.

Cummins ISL CM554 Engines

The 3917440 Belt Tensioner fits the Cummins ISL CM554 engines. These engines are designed for high-performance and are commonly used in demanding industrial environments.

Cummins QSB5.9 44 CM550 Engines

The Belt Tensioner part number 3917440 is also compatible with the Cummins QSB5.9 44 CM550 engines. These engines are known for their reliability and efficiency, making them suitable for a wide range of applications.

Cummins QSC8.3 CM554 Engines

The 3917440 Belt Tensioner is designed to fit the Cummins QSC8.3 CM554 engines. These engines are engineered for durability and are often used in heavy-duty applications.

Cummins QSL9 CM554 Engines

The 3917440 Belt Tensioner fits the Cummins QSL9 CM554 engines. These engines are designed for high-performance and are commonly used in demanding industrial environments.

Role of Part 3917440 Belt Tensioner in Engine Systems

The part 3917440 Belt Tensioner is integral to the efficient operation of several engine components, ensuring optimal performance and longevity.

Interaction with the Alternator

At the alternator location, the Belt Tensioner maintains the necessary tension on the drive belt that connects to the alternator pulley. This ensures consistent power generation and battery charging, preventing slippage that could lead to inefficient operation or complete failure of the alternator.

Drive System Efficiency

Within the drive system, the Belt Tensioner plays a key role by keeping the drive belt properly tensioned. This is essential for the smooth transfer of power from the engine to various auxiliary components. Proper tensioning reduces wear and tear on the belt, enhancing the overall efficiency and reliability of the drive system.

Water Pump Drive

The Belt Tensioner also ensures that the drive belt connected to the water pump pulley is adequately tensioned. This is vital for the water pump’s operation, as it relies on the belt to drive the pump impeller. Consistent tension helps maintain proper coolant circulation, which is essential for engine cooling and preventing overheating.

Pulley Alignment and Performance

By maintaining the correct tension on the belts that interact with various pulleys, the Belt Tensioner aids in aligning these components correctly. This alignment is necessary for the efficient operation of the pulleys, which in turn ensures that components like the alternator and water pump function without undue stress or premature wear.

Conclusion

In summary, the part 3917440 Belt Tensioner is a key component in maintaining the integrity and performance of the engine’s auxiliary systems, ensuring that all interconnected parts operate harmoniously and efficiently.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.