This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

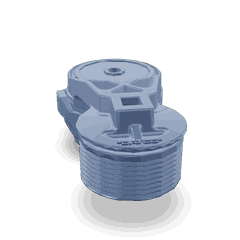

The Cummins 5333481 Belt Tensioner is a component designed to maintain the proper tension of belts within the engine system of commercial trucks. Its role is significant as it ensures that the belts driving various engine components operate efficiently and reliably. Proper tensioning is vital for the optimal performance and longevity of the belts, which in turn supports the overall functionality of the truck’s engine 1.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in engine systems to keep belts at the correct tension. It typically consists of a spring-loaded arm that applies pressure to the belt, ensuring it remains snug against the pulleys it drives. Maintaining proper belt tension is important because it prevents slippage, reduces wear, and ensures that the driven components, such as the alternator, water pump, and air conditioning compressor, operate correctly 2.

Purpose of the 5333481 Belt Tensioner

The Cummins 5333481 Belt Tensioner is specifically designed to maintain optimal belt tension in commercial truck engines. By keeping the belts properly tensioned, it plays a role in ensuring that the various engine components driven by these belts function efficiently. This includes maintaining the correct operation of the alternator for electrical system support, the water pump for cooling, and other auxiliary components 3.

Key Features

The Cummins 5333481 Belt Tensioner features a robust design that incorporates high-quality materials to enhance its performance and durability. Its construction includes precision-machined components to ensure accurate tensioning, and it is built to withstand the demanding conditions found in commercial truck engines. Additionally, the tensioner may include unique characteristics such as a self-adjusting mechanism to maintain consistent belt tension throughout the engine’s operation 4.

Benefits of Using the 5333481 Belt Tensioner

Utilizing the Cummins 5333481 Belt Tensioner offers several advantages. It contributes to improved engine efficiency by ensuring that belts operate without slippage, which can lead to energy loss. Reduced wear on belts is another benefit, as proper tensioning minimizes friction and heat generation. Furthermore, the enhanced durability of the tensioner itself means fewer replacements and lower maintenance costs over time.

Installation Process

Installing the Cummins 5333481 Belt Tensioner requires careful attention to detail. The process involves removing the old tensioner, if present, and ensuring the engine compartment is clean and free of debris. The new tensioner should be aligned with the mounting points and secured according to the manufacturer’s specifications. Tools such as wrenches and socket sets may be required, and it is important to follow the installation instructions provided by Cummins to ensure proper fitment and function.

Troubleshooting Common Issues

Common problems associated with belt tensioners include noise, slippage, and premature wear. Noise can often be attributed to a loose or worn tensioner, while slippage may indicate incorrect tension or a worn belt. Premature wear could be due to improper installation or environmental factors. Troubleshooting steps may involve inspecting the tensioner and belts for signs of wear, ensuring the tensioner is correctly installed, and adjusting the tension as necessary.

Maintenance Tips

Regular maintenance of the Cummins 5333481 Belt Tensioner is key to ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage, ensuring the tensioner operates smoothly, and verifying that the belts remain properly tensioned. Replacement guidelines should be followed to address any issues before they lead to more significant problems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Belt Tensioner 5333481 Compatibility with Cummins Engines

The Belt Tensioner part number 5333481, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the belt and related components.

Compatibility with Specific Engine Models

-

6C8.3: The Belt Tensioner 5333481 is compatible with the 6C8.3 engine, ensuring that the belt tension is maintained correctly, which is essential for the engine’s smooth operation.

-

C GAS PLUS CM556: This part fits the C GAS PLUS CM556 engine, providing the necessary tension to the belt system.

-

G5.9 and G5.9 CM558: Both the G5.9 and G5.9 CM558 engines are compatible with the Belt Tensioner 5333481, ensuring optimal performance and longevity of the belt.

-

ISL9 CM2150 SN and ISL9.5 CM2880 L138: The Belt Tensioner 5333481 is suitable for the ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines, maintaining the correct tension for the serpentine belt.

-

L8.9, L8.9 CM2670 L134C, and L8.9G CMOH2.0 L125B: These engines, including the L8.9, L8.9 CM2670 L134C, and L8.9G CMOH2.0 L125B, are compatible with the Belt Tensioner 5333481, ensuring the belt system operates efficiently.

-

QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850): The Belt Tensioner 5333481 fits the QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850) engines, providing the necessary tension to the belt system.

By ensuring the correct tension of the serpentine belt, the Belt Tensioner 5333481 helps maintain the efficiency and longevity of these Cummins engines.

Role of Part 5333481 Belt Tensioner in Engine Systems

In engine systems, the part 5333481 Belt Tensioner is instrumental in maintaining the proper tension of the drive belt. This ensures efficient operation of various components connected to the belt.

The Belt Tensioner works in conjunction with the Alternator Drive to keep the belt taut, which is essential for the alternator to function correctly. A properly tensioned belt allows the alternator to generate electricity efficiently, powering the vehicle’s electrical systems and recharging the battery.

Additionally, the Belt Tensioner plays a significant role in the overall Drive system of the engine. It ensures that the belt does not slip or become loose, which could lead to inefficient power transmission to other engine components.

The tensioner also interacts with the Tensioner mechanism to automatically adjust the belt tension as needed. This dynamic adjustment helps in accommodating changes in belt wear and thermal expansion, maintaining optimal performance over time.

In summary, the part 5333481 Belt Tensioner is a key component in ensuring that the drive belt remains properly tensioned, thereby supporting the efficient operation of the alternator and other driven components in the engine system.

Conclusion

The Cummins 5333481 Belt Tensioner is a critical component in maintaining the efficiency and reliability of commercial truck engines. By ensuring proper belt tension, it supports the optimal operation of various engine components, contributing to overall engine performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.