This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3685226 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for technicians and fleet managers who aim to maintain optimal truck performance.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure and connect tubing systems in various automotive and industrial applications. They function by compressing the tubing against a fixed surface, creating a secure connection that can withstand pressure and vibration. Tube clamps are integral in systems where fluid transfer is necessary, such as fuel lines, hydraulic systems, and coolant circuits 1.

Purpose of the Cummins 3685226 Tube Clamp

This Cummins part is specifically designed to play a role in the operation of commercial trucks. It is applied in various truck systems where secure and reliable connections of tubing are required. This clamp ensures that the tubing systems remain intact under operational stresses, contributing to the safe and efficient functioning of the truck.

Key Features

This part is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials that offer resistance to corrosion and wear. The design includes elements that allow for easy installation and adjustment, ensuring a secure fit on the tubing. Additionally, the clamp may feature unique attributes such as a locking mechanism to prevent loosening over time.

Benefits of Using the Cummins 3685226 Tube Clamp

Utilizing this Cummins part offers several advantages. It contributes to improved safety by ensuring secure connections in critical systems. The design of the clamp allows for ease of installation, reducing downtime during maintenance routines. Its durability ensures long-term reliability, and its efficiency in securing tubing systems can lead to more streamlined maintenance processes 2.

Installation Process

Installing this part requires following a step-by-step process to ensure a secure fit. The necessary tools may include a wrench for tightening and a screwdriver for any adjustment mechanisms. Best practices involve ensuring the tubing is clean and free of debris before installation, aligning the clamp correctly, and tightening to the manufacturer’s specified torque to achieve the desired compression without overtightening.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or improper fitting, can often be traced back to installation errors or wear and tear. Troubleshooting steps may include inspecting the clamp and tubing for damage, ensuring the clamp is correctly aligned and tightened, and replacing any worn components. Regular checks during maintenance routines can help identify and address these issues before they lead to more significant problems 3.

Maintenance Tips

To ensure the longevity and reliable performance of this part, regular maintenance is recommended. This includes routine inspections for signs of wear or corrosion, ensuring the clamp remains securely tightened, and replacing the clamp if it shows signs of significant wear or if the tubing system undergoes modifications. Adhering to these maintenance tips can help prevent unexpected failures and extend the service life of the clamp.

Compatibility and Applications

This part is designed for use within specific commercial truck systems. Its applications may vary depending on the truck model and the systems in which it is installed. Compatibility with other components or systems should be considered when selecting or replacing tube clamps to ensure optimal performance and integration within the truck’s tubing systems.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the commercial truck and engine industry, Cummins is committed to delivering reliable and efficient products that meet the needs of its customers worldwide.

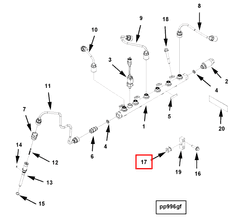

Role of Part 3685226 Tube Clamp in Injector Plumbing

This part is integral to the secure and efficient operation of injector plumbing within engine systems. It ensures that the fuel lines are firmly attached to the injectors, preventing any potential leaks that could compromise engine performance.

In the context of injector plumbing, the Tube Clamp maintains a tight seal around the fuel lines, which is essential for consistent fuel delivery to the injectors. This consistent delivery ensures that the injectors receive the precise amount of fuel needed for optimal combustion, directly influencing the engine’s efficiency and power output 4.

Additionally, the Tube Clamp helps in managing the high pressures present in modern fuel systems. By securely clamping the fuel lines, it prevents any undue stress on the connections, which could lead to failures under pressure. This reliability is particularly important in high-performance engines where fuel delivery precision is paramount.

The Tube Clamp also plays a role in the overall maintenance and serviceability of the injector system. Its design allows for easy disconnection and reconnection of the fuel lines, facilitating quicker and more efficient maintenance procedures. This is beneficial during routine inspections or when modifications to the fuel system are required.

Conclusion

In summary, the Cummins 3685226 Tube Clamp is a key component in ensuring the integrity and performance of injector plumbing, contributing to the overall reliability and efficiency of engine systems.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.