This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

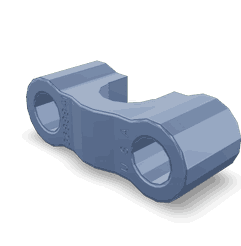

The Cummins 3688841 Tube Clamp is a component designed for securing and connecting tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems, contributing to the overall performance and reliability of the vehicle 4.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing in automotive and industrial applications. They function by providing a tight seal around the tubing, ensuring that fluids or gases are transported efficiently without leaks. Tube clamps are versatile and can be used in a variety of systems, including fuel lines, hydraulic systems, and cooling systems 1.

Purpose of the 3688841 Tube Clamp in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by securing tubing connections in various systems. It is applied in systems such as fuel delivery, hydraulic controls, and cooling circuits. By ensuring a secure and leak-free connection, the clamp contributes to the efficient operation of these systems, which is vital for the truck’s performance and safety 2.

Key Features of the 3688841 Tube Clamp

The design and construction of this part include features that enhance its performance and durability. It is made from materials that resist corrosion and wear, ensuring longevity in demanding truck environments. The clamping mechanism is designed to provide a strong and consistent grip on the tubing, which is crucial for maintaining the integrity of the connection 3.

Benefits of Using the 3688841 Tube Clamp

This part offers several advantages. It provides improved security of tube connections, which is important for preventing leaks and ensuring the efficient transport of fluids or gases. The clamp is also designed for ease of installation and removal, which simplifies maintenance procedures. Its long-term reliability in demanding truck environments makes it a valuable component for commercial truck operators 4.

Installation and Usage Guidelines

Proper installation of this part involves several steps. First, the tubing should be prepared by ensuring it is clean and free of any obstructions. The clamp is then positioned around the tubing, and the tightening procedure is performed to achieve a secure fit. It is important to follow the manufacturer’s guidelines to ensure the clamp is installed correctly and functions as intended 1.

Troubleshooting Common Issues

Common problems with tube clamps may include leaks or improper sealing. These issues can often be addressed by inspecting the clamp for damage or wear, ensuring it is properly tightened, and checking the condition of the tubing. If necessary, the clamp may need to be replaced to restore the integrity of the connection 2.

Maintenance Tips for Longevity

To prolong the life of the 3688841 Tube Clamp, regular maintenance practices should be followed. This includes routine inspections to check for signs of wear or damage, cleaning the clamp and tubing to remove any buildup, and replacing the clamp when it shows signs of significant wear or if it fails to provide a secure connection 3.

Cummins: A Brief Overview

Cummins Inc. is a company with a long history of providing quality products to the commercial vehicle industry. The company offers a wide range of components and systems, with a strong reputation for innovation and commitment to quality. Cummins’ products, including the 3688841 Tube Clamp, are designed to meet the demanding requirements of commercial truck applications 4.

Compatibility with Cummins Engines

This part is compatible with various Cummins engines, ensuring that the cooling and fuel lines are securely fastened. This is crucial for maintaining optimal engine performance and preventing leaks. The compatibility includes:

- ISX12 Series: ISX12 CM2350 X102, ISX12/ISX11.9 CM2250

- ISX15 Series: ISX15 CM2250, ISX15 CM2250 SN, ISX15 CM2350 X101

- QSK19 Series: QSK19 CM2350 K144G

- QSX11.9 Series: QSX11.9 CM2250 ECF

- QSX15 Series: QSX15 CM2250, QSX15 CM2250 ECF, QSX15 CM2350 X105

- X15 Series: X15 CM2350 X116B, X15 CM2350 X123B, X15 CM2450 X134B

Role of 3688841 in Engine Systems

This part is an essential component in the secure and efficient operation of various engine systems. It plays a significant role in maintaining the integrity of injector plumbing by ensuring that the connections between tubes and fittings remain tight and leak-free. This is particularly important in high-performance engines where precision and reliability are paramount 4.

In the context of injector plumbing, the 3688841 Tube Clamp is used to connect fuel lines to injectors. This connection must withstand high pressures and temperatures, making the clamp’s role vital in preventing fuel leaks, which can lead to performance issues or even safety hazards. The clamp ensures that the fuel delivery system operates smoothly, allowing the injectors to deliver the precise amount of fuel required for optimal engine performance 2.

Additionally, the 3688841 Tube Clamp is utilized in various parts of the plumbing system where secure connections are necessary. Whether connecting hoses to fittings or securing tubes to manifolds, the clamp provides a reliable solution that enhances the overall durability and efficiency of the engine system. Its application extends to both fuel and coolant systems, where maintaining a sealed and stable connection is essential for the engine’s consistent operation 3.

Conclusion

The 3688841 Tube Clamp is a fundamental component in ensuring that the injector plumbing and other critical parts of the engine system function correctly. Its reliable performance contributes to the overall efficiency and safety of the engine, making it an indispensable part in the maintenance and upgrade of engine systems 4.

-

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ ↩ -

Williams, Daniel. Generalized Vehicle Dynamics. SAE International, 2022.

↩ ↩ ↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ ↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.