3069053

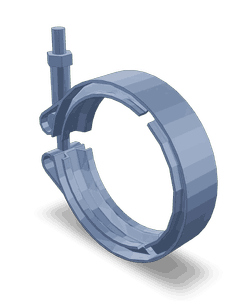

V Band Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to V Band Clamps

V band clamps are essential in various industrial and automotive applications due to their ability to create a tight seal between two surfaces. These clamps feature a V-shaped band that, when tightened, applies pressure to the surfaces it clamps, effectively preventing leaks and ensuring a secure fit. The design of V band clamps facilitates easy assembly and disassembly, making them particularly suitable for high-pressure environments 1.

The Role of Cummins 3069053 V Band Clamp in Engines

The Cummins 3069053 V band clamp is specifically designed for use in commercial truck engines. Its main function is to secure and seal critical components such as exhaust manifolds, turbochargers, and other parts where a reliable and leak-proof connection is essential. By maintaining a tight seal, this Cummins part ensures that the engine operates efficiently and safely, minimizing the risk of leaks that could lead to performance issues or damage 2.

How Cummins 3069053 V Band Clamp Works

The operation of the Cummins 3069053 V band clamp is both simple and effective. The V-shaped band is positioned around the components that need to be sealed, and a bolt and nut system is used to tighten the clamp. As the bolt is tightened, the V band applies pressure to the surfaces it clamps, creating a seal that prevents the passage of fluids or gases. This mechanism is vital for maintaining the integrity of the engine’s exhaust system and other components that require a secure connection 3.

Troubleshooting and Maintenance

Proper maintenance of the Cummins 3069053 V band clamp is crucial to ensure its longevity and effectiveness. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. If any issues are detected, the clamp should be replaced promptly to prevent leaks or other problems.

In the event of a leak, the first step is to identify the source. This may involve removing the clamp and inspecting the surfaces it seals. If the surfaces are damaged or worn, they should be replaced before reinstalling the clamp. Additionally, ensuring that the bolt and nut system is properly tightened is essential to maintaining a secure seal 4.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components, known for its commitment to quality and innovation. The company’s products are used in a wide range of applications, from commercial trucks to industrial machinery. Cummins’ expertise in engine technology ensures that its components, including the 3069053 V band clamp, are designed to meet the highest standards of performance and reliability 5.

Expert Insights and Best Practices

For engineers and mechanics working with the Cummins 3069053 V band clamp, it is important to follow best practices to ensure optimal performance. This includes using the correct torque specifications when tightening the clamp, inspecting the surfaces it seals for damage or wear, and replacing any damaged components before reassembling. Additionally, staying up-to-date with the latest maintenance guidelines and troubleshooting techniques can help prevent issues and extend the life of the clamp 6.

V Band Clamp 3069053 Compatibility with Cummins Engines

The V Band Clamp part number 3069053, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring a secure and reliable seal in various applications. Below is a detailed breakdown of the engines that this part is compatible with:

4B3.9, 6B5.9, 6C8.3, B5.9 CM2670 B166C, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, C8.3 G, G8.3, G855, G855 CM558, GTA855 CM558 (CM2358) G101, ISB CM550, ISB5.9 CM2880 B127, ISB5.9G CM2180, ISBE CM2150, ISBE4 CM850, ISC CM554, ISL CM554, ISL9 CM2150 SN, ISL9.5 CM2880 L138, ISM CM570

These engines, while differing in specifications and applications, share common design elements that allow the V Band Clamp 3069053 to fit seamlessly. The clamp is engineered to provide a tight and durable seal, crucial for maintaining the integrity of the engine’s systems. Its compatibility with these engines ensures that it can be used in various configurations, from industrial to heavy-duty applications.

L10 CELECT, L10 GAS, L8.9

The V Band Clamp 3069053 is also compatible with the L10 CELECT, L10 GAS, and L8.9 engines. These engines, while part of a different series, benefit from the clamp’s ability to create a reliable seal, essential for preventing leaks and ensuring optimal performance.

The V Band Clamp 3069053’s versatility and compatibility with a wide range of Cummins engines make it a valuable component for maintaining and repairing these engines. Its design ensures that it can be used across different engine models, providing a consistent and reliable solution for sealing needs 7.

Role of Part 3069053 V Band Clamp in Engine Systems

The Part 3069053 V Band Clamp is instrumental in ensuring secure and efficient connections across various components within engine systems. Its application spans multiple critical junctions, enhancing the overall performance and reliability of the engine.

Turbocharger Connections

In turbocharger arrangements, the V Band Clamp is employed to connect the turbocharger to the engine air intake and the turbine compressor outlet. This secure fitting ensures that the airflow is maintained without leaks, which is essential for optimal turbocharger performance. The clamp’s design allows for easy installation and removal, facilitating maintenance and upgrades.

Air Intake and Air Cleaner Connections

The V Band Clamp plays a significant role in connecting the air intake to the air cleaner. This connection is vital for filtering incoming air before it enters the engine, ensuring that contaminants are removed and the engine operates efficiently. The clamp’s robust design withstands the vibrations and pressures inherent in the air intake system.

Air Crossover and Air Transfer Connections

For engines with multiple cylinders, the V Band Clamp is used in air crossover and air transfer connections. These connections allow for balanced air distribution across the engine, which is essential for uniform combustion and performance. The clamp ensures that these connections remain tight and leak-free, maintaining the integrity of the air supply system.

Hose and Plumbing Connections

In the engine’s plumbing system, the V Band Clamp is utilized to connect various hoses that transport air and other fluids. These connections must be secure to prevent leaks and ensure that the engine receives a consistent supply of necessary components. The clamp’s versatility allows it to be used in a wide range of hose diameters and materials.

Mounting and Intake Connections

The V Band Clamp is also crucial in mounting and intake connections, where it secures components to the engine frame and other structural elements. This ensures that the engine’s components remain in place under operating conditions, contributing to the engine’s stability and performance. The clamp’s ease of use makes it a preferred choice for both initial installation and subsequent maintenance.

Conclusion

By understanding the basic concepts, purpose, and maintenance of the Cummins 3069053 V band clamp, engineers, mechanics, truck drivers, and fleet operators can ensure that their commercial trucks operate efficiently and reliably. This comprehensive guide provides the necessary information to make informed decisions and maintain the integrity of critical engine components.

-

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4332747.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4332747.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4332747.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4332747.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.