This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

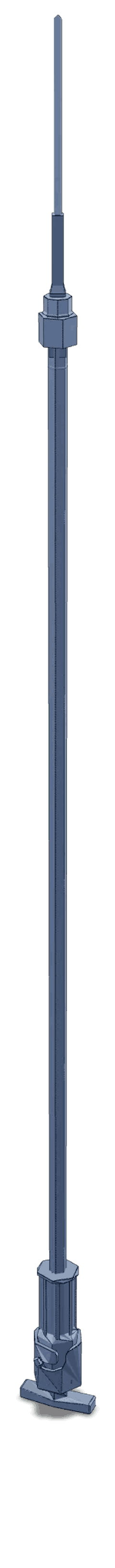

The Cummins 4007930 Dipstick is a specialized tool designed for use in heavy-duty trucks equipped with Cummins engines. Its primary function is to facilitate the accurate measurement of engine oil levels, which is vital for maintaining the engine’s performance and longevity. Regular monitoring of oil levels helps ensure that the engine operates within optimal parameters, reducing the risk of damage due to insufficient lubrication 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential component in an engine’s lubrication system. It operates by being inserted into the engine’s oil sump, where it comes into contact with the oil. Once removed, the oil level can be read from the markings on the dipstick, providing an indication of whether the oil level is within the acceptable range. This information is critical for assessing the engine’s condition and determining if an oil change or top-up is necessary 2.

Purpose of the Cummins 4007930 Dipstick

The Cummins 4007930 Dipstick is specifically engineered to meet the demanding requirements of heavy-duty truck engines. It plays a role in the maintenance routine by allowing technicians to check the oil level with precision. This ensures that the engine is adequately lubricated, which is fundamental for its efficient operation and durability. The dipstick’s design caters to the unique characteristics of Cummins engines, providing reliable readings that are essential for preventive maintenance 3.

Key Features

This Cummins part is constructed from high-quality materials to withstand the harsh conditions present in heavy-duty truck engines. Its design includes a robust handle for easy gripping and a long, durable shaft that can reach the oil sump without bending. The dipstick is marked with clear, easy-to-read indicators for minimum and maximum oil levels, ensuring accurate readings. Additionally, its construction is resistant to corrosion and high temperatures, enhancing its longevity and reliability in demanding environments 4.

Benefits of Using the Cummins 4007930 Dipstick

Utilizing the Cummins 4007930 Dipstick offers several advantages. Its precise markings contribute to accurate oil level readings, which are crucial for maintaining engine health. The ease of use, combined with its durable construction, ensures that it can withstand frequent use without degradation. Furthermore, by facilitating regular and accurate oil level checks, the dipstick contributes to the overall longevity of the engine by ensuring it remains properly lubricated 5.

Troubleshooting and Maintenance Suggestions

Common issues with dipsticks may include inaccurate readings due to wear or contamination. To address these problems, it is advisable to inspect the dipstick regularly for signs of damage or buildup. Cleaning the dipstick with a suitable solvent can remove contaminants that may affect its accuracy. Additionally, ensuring that the dipstick is fully seated when taking readings can help avoid errors. Regular maintenance of the dipstick contributes to its longevity and the accuracy of oil level readings 6.

Installation and Usage Instructions

To install and use the Cummins 4007930 Dipstick, first, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, usually found near the engine’s center. Pull the dipstick out completely, wipe it clean with a lint-free cloth, reinsert it fully, and then remove it again to check the oil level. The oil should be between the minimum and maximum marks. If the level is low, add the recommended type of oil until it reaches the appropriate level 7.

Safety Considerations

When using the Cummins 4007930 Dipstick, it is important to follow safety guidelines to prevent injury or damage to the engine. Always ensure the engine is off and cool before checking the oil level to avoid burns. Use caution when handling the dipstick to prevent oil spills, which can be slippery and hazardous. Additionally, dispose of used oil and cleaning materials according to local environmental regulations to minimize environmental impact 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the production of diesel engines and related components. The company’s commitment to innovation, quality, and customer satisfaction has made it a preferred choice for heavy-duty applications, including trucks and industrial equipment 9.

Cummins Engine Dipstick Part 4007930

The Cummins part 4007930, a Dipstick, is an essential component for maintaining the operational integrity of certain Cummins engines. This part is integral to the maintenance and monitoring processes of the engines, ensuring that the oil levels are checked regularly to prevent any operational issues 10.

Application in Cummins Engines

The Dipstick part 4007930 is designed to fit seamlessly into the following Cummins engines:

- QSK78

- CM500

These engines are known for their robust performance and reliability, often used in heavy-duty applications. The dipstick’s role in these engines is crucial for ensuring that the oil levels are maintained within the optimal range, which is vital for the engine’s longevity and efficiency 11.

Importance of the Dipstick

Regular checks using the dipstick are a fundamental part of engine maintenance. The dipstick allows for a quick and easy assessment of the oil level, ensuring that the engine is neither overfilled nor underfilled. This simple yet critical task helps in preventing potential engine damage and ensures that the engine operates smoothly 12.

Compatibility and Fitment

The design of the Cummins Dipstick part 4007930 ensures a precise fit in the specified engines. This compatibility is achieved through meticulous engineering and quality control processes, ensuring that the dipstick functions effectively and reliably in its intended applications 13.

Maintenance and Usage

For operators and maintenance personnel, using the dipstick part 4007930 is straightforward. It involves pulling the dipstick out, wiping it clean, reinserting it fully, and then pulling it out again to check the oil level. This process should be performed regularly as part of the engine’s maintenance schedule 14.

Ensuring Proper Function

To ensure the dipstick functions correctly, it is important to use the correct part number and to follow the manufacturer’s guidelines for maintenance. This includes checking the dipstick for any signs of wear or damage and replacing it if necessary to maintain the accuracy of oil level readings 15.

Role of Part 4007930 Dipstick in Engine Systems

The part 4007930 dipstick is an essential component in the engine system, specifically designed to interact with the oil level gauge and the location of the oil reservoir.

Interaction with Oil Level Gauge

The dipstick serves as a direct interface between the oil reservoir and the oil level gauge. When inserted into the oil filler tube, the dipstick collects a sample of the engine oil. Upon removal, the oil level can be visually assessed against the marked gauge on the dipstick. This interaction ensures that the oil level gauge provides accurate readings, allowing for precise monitoring of the oil level within the engine 16.

Placement and Functionality at the Oil Reservoir Location

Positioned at the oil reservoir location, the dipstick allows for easy access to the engine oil. Its strategic placement ensures that it can effectively reach the oil within the reservoir, providing a reliable method for checking the oil level without the need for more invasive procedures. This placement is vital for maintaining the engine’s lubrication system, as it enables regular checks and timely top-ups, preventing oil starvation and potential engine damage 17.

Conclusion

In summary, the Cummins 4007930 Dipstick plays a significant role in the engine system by facilitating accurate oil level measurements and ensuring the oil reservoir is easily accessible for maintenance purposes. Regular use of this part contributes to the longevity and efficient operation of Cummins engines, underscoring its importance in preventive maintenance routines 18.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021555, Master Repair Manual.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021555, Master Repair Manual.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021555, Master Repair Manual.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021555, Master Repair Manual.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.