This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

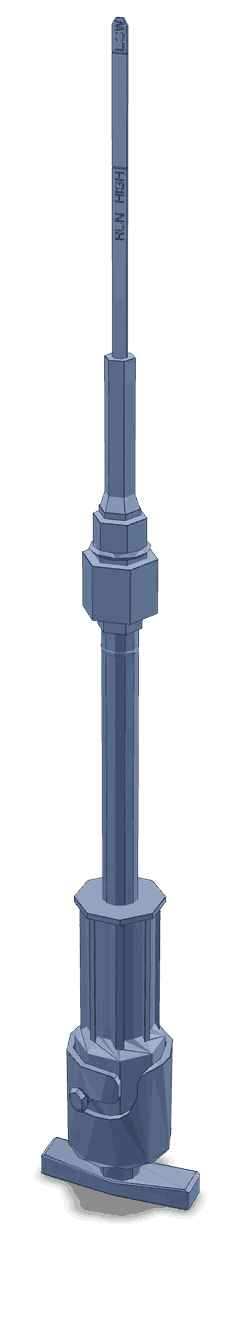

The Cummins 4380996 Oil Level Gauge is a specialized component designed for use in commercial trucks. Its purpose is to monitor the oil levels within the engine, providing data that aids in the maintenance and operation of these vehicles. Accurate oil level monitoring is significant for ensuring the engine operates efficiently and has a prolonged service life.

Basic Concepts of Oil Level Gauges

An oil level gauge is a device that measures the amount of oil present in an engine. It functions by utilizing a float or sensor that moves in response to the oil level, translating this movement into a readable measurement. The importance of an oil level gauge in engine maintenance cannot be overstated, as it ensures that the engine is neither overfilled nor underfilled with oil. Proper oil levels are vital for lubrication, cooling, and overall engine health. The technology used in these gauges often includes mechanical floats, electronic sensors, or a combination of both, depending on the design and application 1.

Purpose of the Cummins 4380996 Oil Level Gauge

This Cummins part plays a role in the operation of a truck by providing real-time information on the engine’s oil levels. This gauge assists in monitoring oil levels to ensure that the engine maintains optimal performance and longevity. By keeping the oil levels within the recommended range, the gauge helps prevent engine wear, overheating, and potential damage due to insufficient lubrication.

Key Features

The Cummins 4380996 Oil Level Gauge is characterized by several key features that enhance its functionality. Its design incorporates durable materials that can withstand the harsh environments typical of commercial truck operations. The gauge may include a clear viewing window for easy reading, a robust housing to protect internal components, and precise calibration for accurate measurements. Additionally, any unique technological aspects, such as electronic sensors for enhanced accuracy or wireless connectivity for remote monitoring, would be highlighted as part of its feature set.

Benefits of Using the Cummins 4380996 Oil Level Gauge

Incorporating this part into truck maintenance routines offers several advantages. It contributes to improved engine performance by ensuring that the engine is properly lubricated. This, in turn, can lead to extended engine life, as consistent oil levels help reduce wear and tear on engine components. Furthermore, accurate oil level monitoring enhances safety by preventing situations where the engine could seize due to low oil levels or suffer from reduced efficiency due to overfilling.

Installation and Usage

Proper installation and usage of the Cummins 4380996 Oil Level Gauge involve several steps to ensure it integrates seamlessly into the truck’s system. The installation process typically includes mounting the gauge in a location that is easily accessible for readings, connecting it to the engine’s oil system, and calibrating it according to the manufacturer’s specifications. Best practices for usage involve regularly checking the oil levels as part of routine maintenance checks and responding promptly to any indications of low or high oil levels.

Troubleshooting and Maintenance

Common issues with the Cummins 4380996 Oil Level Gauge may include inaccurate readings, gauge malfunctions, or physical damage. Troubleshooting steps can involve checking the gauge’s connections, recalibrating the gauge, or inspecting it for any signs of wear or damage. Maintenance tips to ensure the gauge remains accurate and reliable over time include keeping the gauge clean, protecting it from physical damage, and performing regular calibration checks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, known for its commitment to quality and innovation in automotive components. The company’s dedication to advancing technology and improving efficiency is evident in its product offerings, including the Cummins 4380996 Oil Level Gauge 2.

Cummins Oil Level Gauge 4380996 Compatibility

The Cummins Oil Level Gauge, part number 4380996, is designed to provide accurate readings of the oil level, ensuring that the engine operates within optimal parameters.

Engine Compatibility

-

QSK78 Series

- The QSK78 series engines, known for their robust performance and reliability, integrate the Oil Level Gauge 4380996 seamlessly. This part ensures that operators can monitor oil levels effectively, preventing potential engine damage due to low oil conditions.

-

CM500 Series

- The CM500 series engines, which are widely used in various industrial applications, also benefit from the precise oil level monitoring provided by the 4380996 Oil Level Gauge. This compatibility ensures that the engine’s oil levels are consistently monitored, contributing to the longevity and efficiency of the engine.

Installation and Functionality

The installation of the Oil Level Gauge 4380996 in these engines is straightforward, designed to fit snugly into the specified mounting points. This ensures that the gauge provides accurate and reliable readings, which are crucial for the maintenance and performance of the engines.

Role of Part 4380996 Oil Level Gauge in Engine Systems

This part is an essential component in maintaining the operational integrity of engine systems. It is strategically positioned to monitor the oil level within the engine, ensuring that it remains within the optimal range for efficient performance.

Integration with Engine Components

-

Oil Pan: The gauge is typically connected to the oil pan, where it measures the oil level. This connection allows for real-time monitoring of the oil volume, which is vital for preventing engine damage due to low oil levels.

-

Oil Pump: By maintaining the correct oil level, the gauge indirectly supports the oil pump’s function. Adequate oil levels ensure that the pump can circulate oil effectively throughout the engine, lubricating moving parts and reducing friction.

-

Oil Filter: Consistent oil levels, as monitored by the gauge, contribute to the efficient operation of the oil filter. Proper lubrication ensures that the filter can capture contaminants without becoming clogged prematurely.

-

Crankshaft and Camshaft: The gauge plays a role in protecting these critical components by ensuring that there is sufficient oil to lubricate their surfaces. This lubrication is essential for the smooth operation and longevity of these parts.

-

Pistons and Cylinders: Adequate oil levels, as indicated by the gauge, are necessary for maintaining the lubrication between pistons and cylinder walls. This reduces wear and tear, enhancing engine efficiency and durability.

-

Valve Train: The gauge helps in maintaining oil levels that are crucial for the lubrication of the valve train components. Proper lubrication prevents excessive wear on valves and lifters, ensuring consistent engine performance.

-

Sensors and ECU: Modern engines often integrate the oil level gauge with sensors that communicate with the Engine Control Unit (ECU). This integration allows for automated alerts and adjustments, enhancing overall engine management.

Conclusion

In summary, the Cummins 4380996 Oil Level Gauge is a key component in the engine system, ensuring that all moving parts are adequately lubricated and that the engine operates within safe parameters. Its role in monitoring oil levels directly impacts the longevity and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.